Procedure – MTS 318 Load Unit User Manual

Page 101

Routine Maintenance Overview Checklist

318 Load Unit

Maintenance

101

Procedure

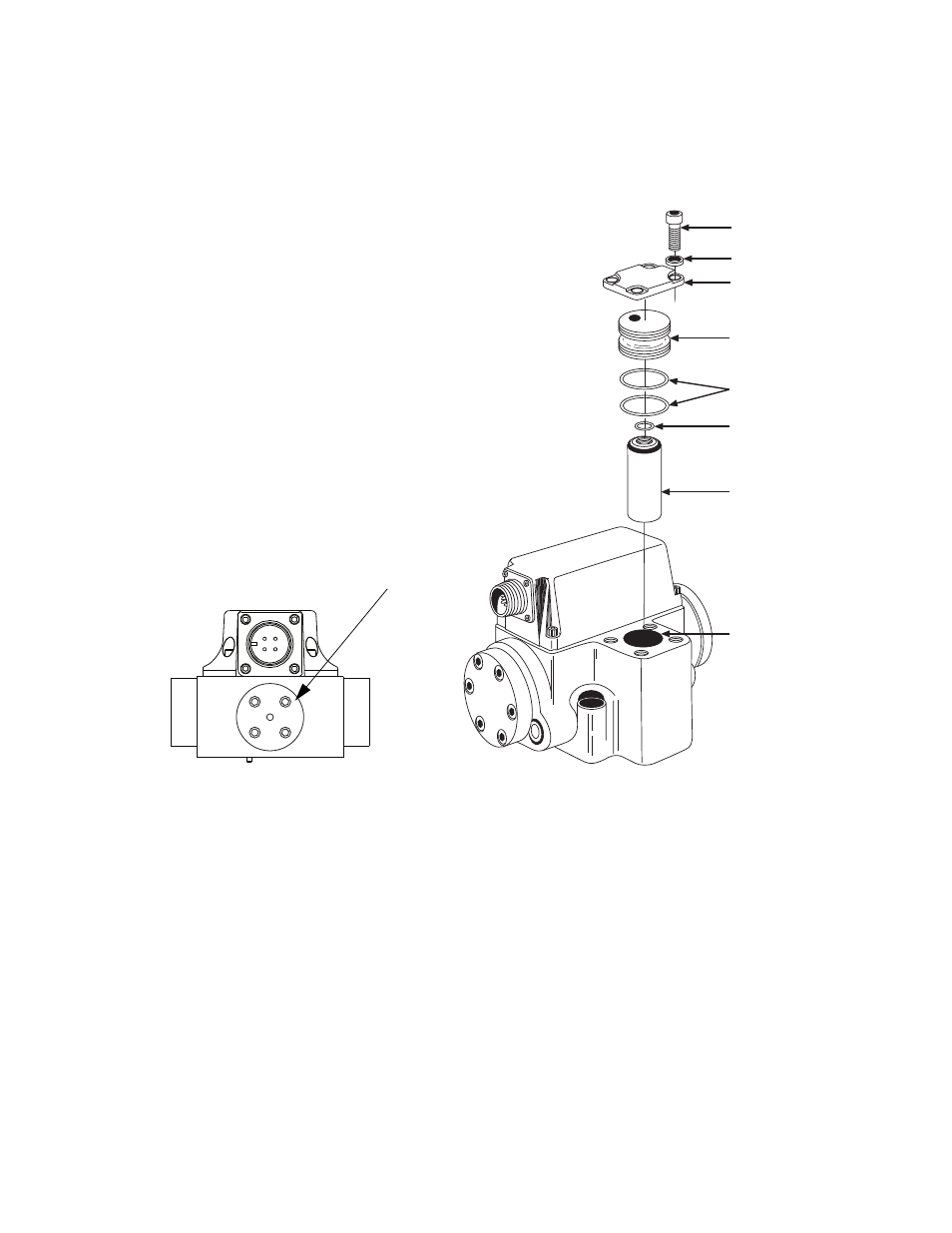

To replace the filter element, perform the following procedure. Care should be

exercised to prevent dirt or other contaminants from entering the servovalve

body, filter passages, or manifold/actuator ports. Refer to the following figure

during the procedure.

10. Ensure that system hydraulic pressure has been reduced to zero before

proceeding. To do this, turn off the hydraulic power unit and exercise the

actuator until it stops moving. Turn off electrical power to the controller.

For the Series 252.2x/4x Servovalve proceed as follows:

Note

This procedure only applies to revision G of the servovalve.

A. Remove the four socket head screws and washers that secure the filter

cover plug.

B. Thread one of the socket head screws, removed in Step A, into the filter

cover plug and pull it out of the filter housing.

C. Remove the filter disk.

1

4

3

2

Socket Head

Screws (4)

Filter Cover

Plate

Filter Plug

Filter Plug

O-Rings

Filter O-Ring

Filter

Filter Housing

Filter Cover

Model 252.2x/.4x Filter Location

(Revision G only)

Model 252.3x Filter Assembly