Mk-1600 maintenance – MK Diamond MK-1600 Series User Manual

Page 24

24

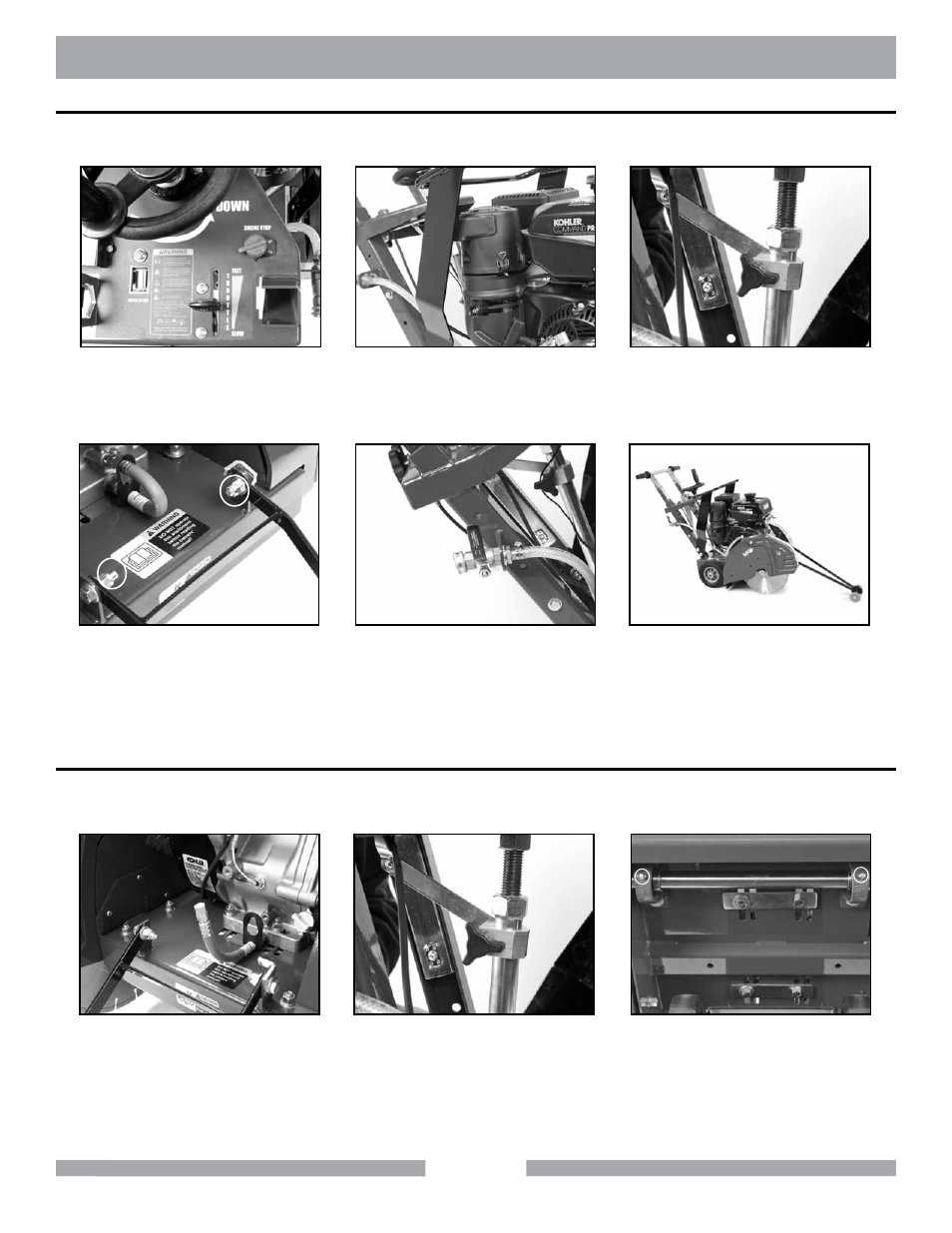

MK-1600 MAINTENANCE

Maintenance Following Use

The following maintenance should be performed following each use.

(A)

Shut down the Engine. Let saw

cool before proceeding.

(B)

Check Air Filter

(See Engine Manual).

(C)

Lubricate the Grease Fitting.

(D)

Lubricate the pivot point of the

Pointer.

(E)

Lubricate the Cooling

Supply Valve.

(F)

Verify the tightness of all bolts

and screws. Clean the saw (ex-

cept the engine) with soap and

water.

Weekly (50 hours) and Monthly (200 hours)

The following should be performed monthly. Items should be lubricated using waterproof grease.

(A)

Change engine oil every 100

hours. Refer to Engine Manual

for details.

(B)

Lubricate the Depth Control

Screw (Monthly).

(C)

Lubricate the Blade Shaft Bear-

ings (Monthly).

See also other documents in the category MK Diamond Power saws:

- MK-770 (41 pages)

- MK-770 EXP (46 pages)

- MK-660 (44 pages)

- MK-470 (12 pages)

- MK-377 (36 pages)

- MK-370 (36 pages)

- MK-370 EXP (52 pages)

- MK-170 (36 pages)

- MK-145 (32 pages)

- MK-145 220 Volt (32 pages)

- MK-101 (52 pages)

- MK-101 (56 pages)

- MK-101-24 (52 pages)

- MK-101-24 (56 pages)

- MK-101 Pro / Pro24 (56 pages)

- MK-101 Tracker (45 pages)

- MK-101Pro24 JCS (60 pages)

- MK-101 JCS Rental (51 pages)

- MK-101 Lowes (56 pages)

- MK-101 Lowes (52 pages)

- MK-100 (44 pages)

- MK-100 (52 pages)

- MK-100 Tracker (46 pages)

- MK-100 JCS (49 pages)

- TX-3 (52 pages)

- Saw Tent (2 pages)

- MK-112 (28 pages)

- MK-1070 (22 pages)

- MK-212 (52 pages)

- MK-1590 (36 pages)

- MKDX Profile Milling Machine (40 pages)

- MK-EZ Profile Milling Machine (36 pages)

- MK-1503SS (24 pages)

- MK-1080 (44 pages)

- MK-1080 (1 page)

- MK-1080 (3 pages)

- MK-1280 Gas Saw (48 pages)

- MK-1280 Electric Saw (40 pages)

- MK-1280 Rolling Cart (4 pages)

- MK-1270 (Shindaiwa) (28 pages)

- MK-2000 Electric Saws (52 pages)

- MK-2000 Gas (60 pages)

- MK-5005S (56 pages)

- MK-5000 Gas Saws (56 pages)

- BX-3 (36 pages)