Mk-1600 operation – MK Diamond MK-1600 Series User Manual

Page 19

19

MK-1600 OPERATION

Standard Operation

The MK-1600 is intended for industrial applications and operated by experienced professionals. The

operator must be aware of the machine’s capabilities and limitations. It is the operators responsibility

to use this machine under safe working conditions and conform with federal, state and local codes or

regulations pertaining to safety, air, pollution, noise etc...

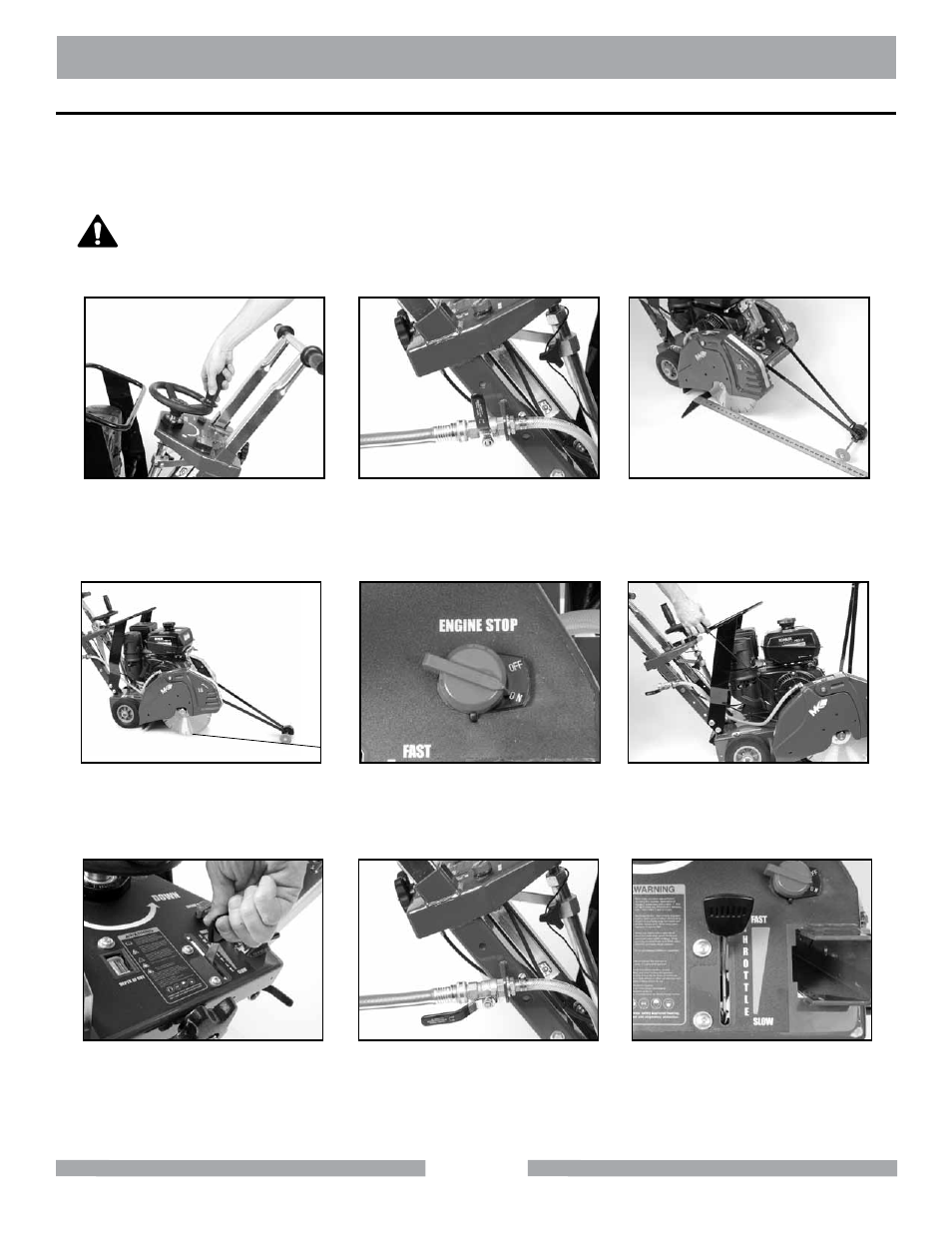

(A)

Use the Depth Control Wheel to

raise the blade clear of the floor.

(B)

Attach the cooling supply

hose to the Cooling Inlet, if

wet cutting.

(C)

Lower the Pointer. Using a Straight-

edge, align the Pointer to the Blade

see “Front Pointer Alignment.”

(E)

Place Engine Master Switch in

the “ON” Position.

(D)

Layout and mark the area to

be cut using a chalk-line. Align

Pointer and Blade to chalk-line.

(F)

Start the Saw using the Engine Start

procedure in the engine manual.

Prior to operation of this machine the operator must determine the existence and

location of any subsurface features that may be hazardous or could damage the

equipment, (i.e. electric cable, natural gas line etc...)

CAUTION

(G)

With the engine running adjust

the throttle approximately half-

way.

(H)

For Wet Cutting, open Cooling

Supply Valve. Verify proper cool-

ing flow and adjust the water flow

on the Blade to a desired amount.

(I)

Move the throttle all the way for-

ward to “Fast” position.