Seam-loc 24, Ul 580 w – Metal Sales Seam-Loc 24 Manual User Manual

Page 7

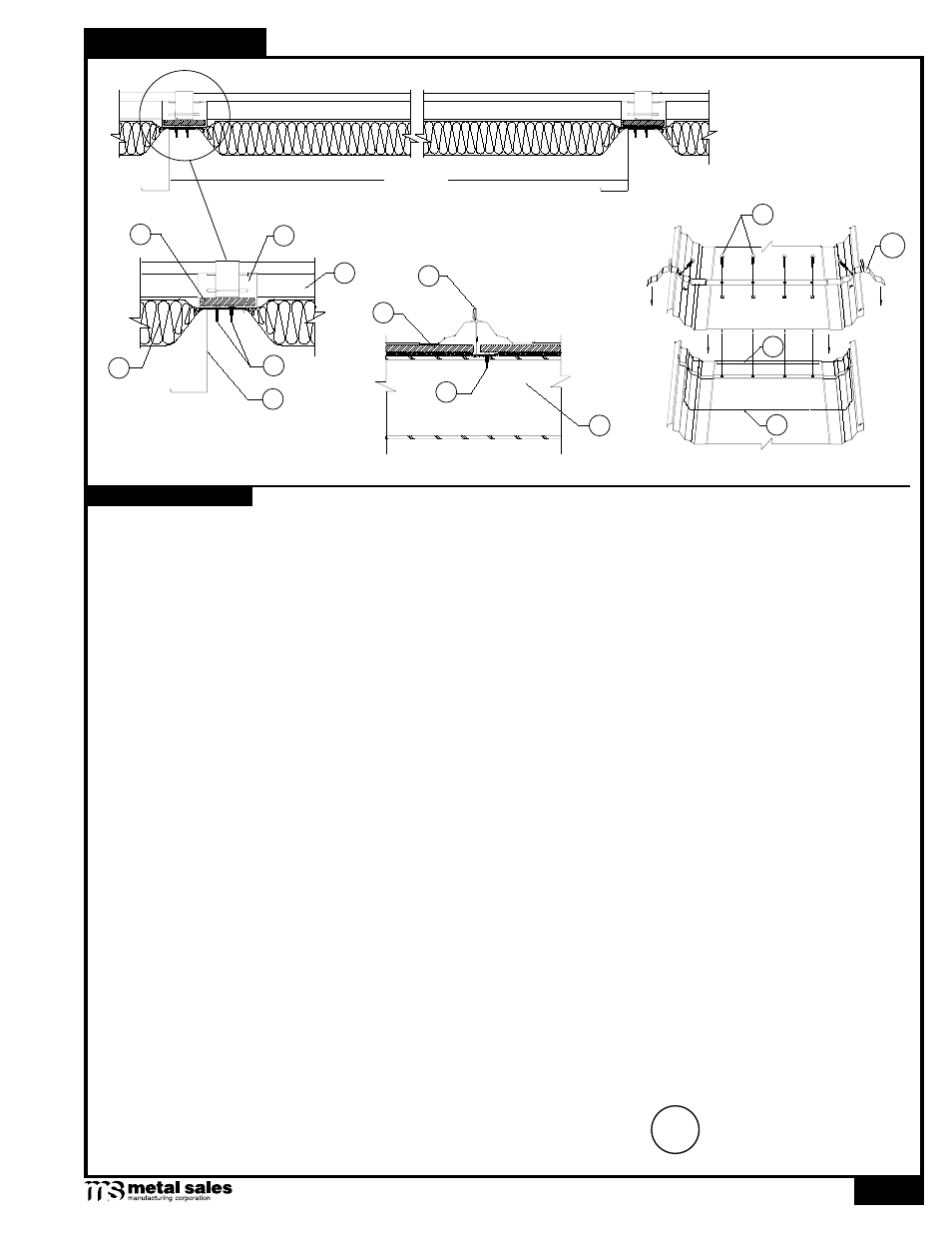

Construction No. 197

February 14, 2001

Wind Uplift - Class 90

Fire Not Investigated

1. Metal Roof Deck Panels* No. 24 MSG min thickness coated steel. Panels continuous over two or more spans. End

laps to occur over purlins with panels overlapped 3 in. Adjacent panels to be continuously seamed with an electric seamer

with seaming operation to include roof deck fasteners (Item 2). A line of sealant may be used at panel end-laps and side

joints.

METAL SALES MANUFACTURING CORPORATION - “Seam-Loc 24”

2. Roof Deck Fasteners* (Panel clips) Two part assembly consisting of a base and a tab. Base 5 in. wide, fabricated from

No. 14 MSG thick coated steel. Tab fabricated from min No. 22 MSG thick coated steel. Height of clip to vary depending

on insulation thickness or type and use of thermal spacer. Clips located at sides of roof deck panels.

METAL SALES MANUFACTURING CORPORATION - “Seam-Loc 24 Panel Clip”

3. Fasteners (Screws) Fasteners used for panel clip to purlin attachment to be No. 14 by 1-1/2 in. long self-drilling, self-

tapping, hex-washer-head plated steel screws with a separate washer. Two screws per panel clip to be used. Fasteners

used at the end lap section to be No. 12-14 by 1-1/4 in. long self-drilling, self-tapping, hex-head, plated steel screws with

a separate 5/8 in. OD steel washer and a neoprene sealing washer. One screw located in each 1-1/2 in. flat area adjacent

to panel ribs driven through panels to end lap back up plate. Four screws used in panel flat area spaced 4 in. OC driven

through cinch strap and panels into back up plate. One screw driven through cinch strap at side of panel ribs into back up

plate. A total of eight screws to be used.

4. Insulation Any compressible blanket type, 4 in. max thickness before compression.

5. Thermal Spacer (Optional) Used over purlins between panel clips; 1 in. thick, 3 in. wide, cut to fit between panel clips.

Fabricated from beaded plastic.

5A. Foamed Plastic (Rigid Insulation) Not Shown - Optional - Not used when thermal spacer (Item 5) is used. Maximum

1 in. thick. Supplied in 4 ft. wide sheets. Butt joints to occur over purlins.

6. Purlins No. 16 MSG min thickness. (50,000 psi minimum yield strength). Spacing 60 in. OC.

7. End-Lap Back-Up Plate *(Optional) Length 20 in., with ends formed to the general profile of the panel side ribs. Width

to be 9-1/4 in. A 14 in. long by 1 in. long by 1 in. wide return formed along on edge of the plate. Fabricated from 0.047 in.

thick coated steel.

METAL SALES MANUFACTURING CORPORATION - “Seam-Loc 24 Compression Plate”

7A. Cinch Strap *(Optional) Used over the panels, to be 1 in. wide, formed of 0.089 in. thick aluminum to the general

profile of the panel, with both ends formed to fit over the panel ribs.

METAL SALES MANUFACTURING CORPORATION - “Seam-Loc Cinch Strap”

8. Lateral Bracing (Not Shown) - As required.

Refer to General Information, Roof Deck Construction for items not evaluated.

*Bearing the UL Classification Mark

PSL-7

SEAM-LOC 24

®

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

Ul 580 w

ind

U

PlifT

i

nformaTion

SEAM-LOC 24

1

3

2

5

6

1

3

4

7A

5

6

60" MAX

7

7

3

Underwriters Laboratories Inc.

®

UL

®

LISTED