Seam-loc 24, Caution – Metal Sales Seam-Loc 24 Manual User Manual

Page 16

PSL-16

SEAM-LOC 24

®

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

d

esign

/ i

nsTallaTion

C

onsideraTions

(

ConT

)

CAUTION

Do not run the seamer off the end of the panel. If the seamer is run off the end of the roof it

could cause injury to personnel and damage the roof or the seamer (see seamer instructions

enclosed in the case for additional information about the proper handling of the seamer).

SEAMING PANELS

(CONT.)

At completion of seaming, repack tool and return to:

Seamer Tools, Inc.

8265 Highway 178 Olive Branch, MS 38654.

Phone No. (662) 895-1222, Fax No. (662) 890-4775.

STEP 3 - Electric Seaming:

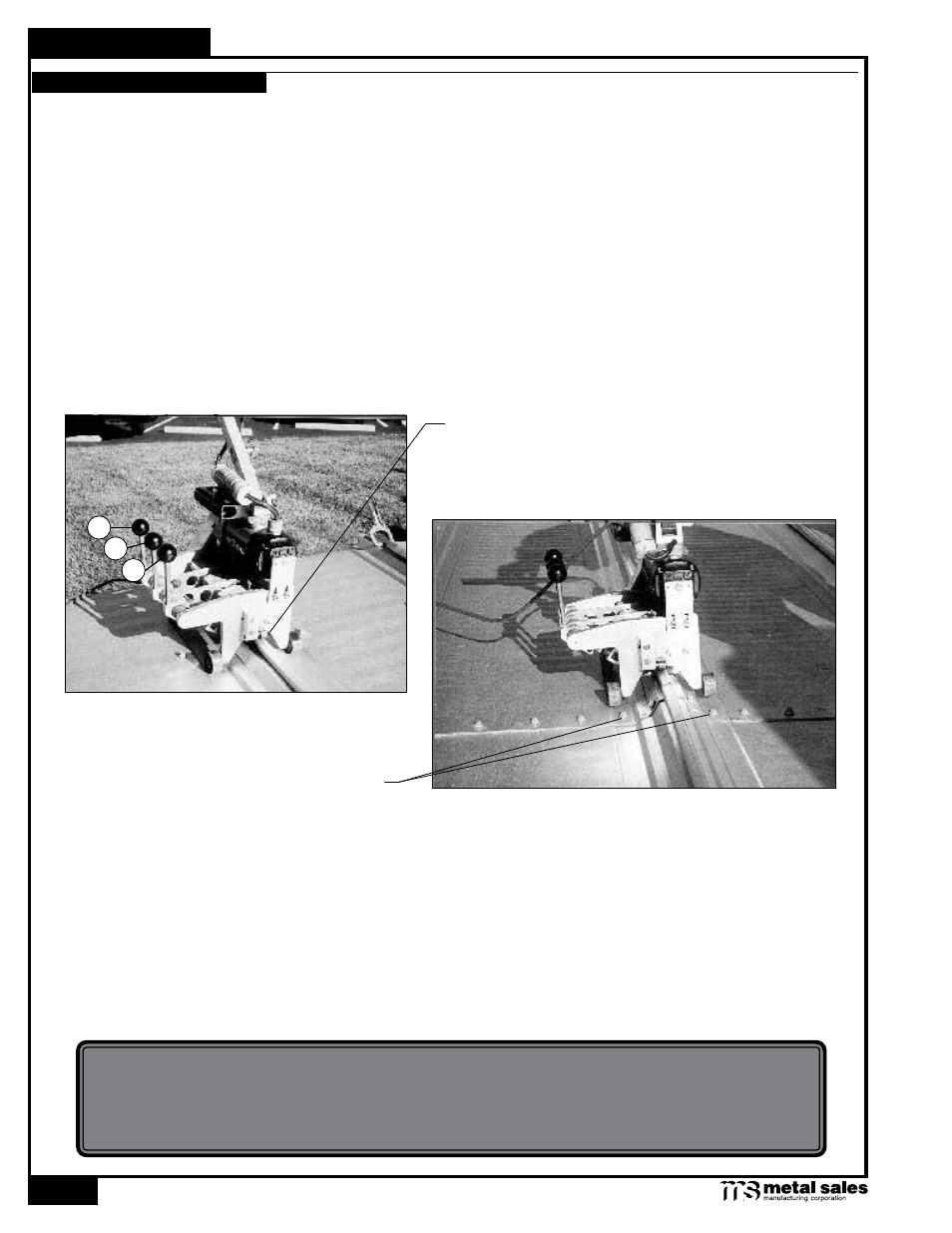

A. Place the electric seamer in position at the start end of the panel and engage the three handles to the fully locked position.

Pull the handles in order of #1, #2, and #3 (See Photo 3A). Make sure the forming rolls are on the open side of the panel rib.

Start the electric seamer and let run for 2 feet. Stop electric seamer and check seam. Continue if seam is correct.

B. Stop electric seamer before endlap screws in panel at endlap condition (See Photo 3B). Failure to stop before these screws

will cause electric seamer wheels to hit screws and disengage electric seamer. Disengage the electric seamer from the panel and

hand crimp endlap condition and 8-10 inches past endlap per Step 1 and Step 2. Move electric seamer to other side of endlap and

continue seaming.

C. Disengage the electric seamer from the panel and move it to the start of the next panel rib.

NOTE: The Seam-Loc 24 electric seamer is a single direction machine. If panels are installed from left to right (looking

from eave to ridge), electric seamer will run down slope from ridge to eave. If panels where installed on a gable building

from one side of the building to the other, the seamer will start at the ridge on one side of the building and start at the

eave on the other side of the building.

Panel ends, panel endlap conditions or any other areas, that the electric seamer did not seam will need to be hand crimped to

complete seam as outlined in Step 1 and 2.

NOTE: Do NOT hand crimp per Step 2 at any panel clips.

NOTE: Keep the forming rolls on the seamer CLEAN

3

2

1

Roller bearing will ride on top of panel rib.

Photo 3A Electric Seaming

Photo 3B Electric Seaming at Endlap

Stop seamer at Endlap screws.