Seam-loc 24 – Metal Sales Seam-Loc 24 Manual User Manual

Page 15

PSL-15

SEAM-LOC 24

®

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

d

esign

/ i

nsTallaTion

C

onsideraTions

(

ConT

)

SEAMING PANELS

Note: The Seam-Loc 24 panel system requires the use of a mechanical seamer for proper installation. The mechanical

seamer runs from ridge to eave with Seam-Loc 24 panels laid from left to right. This necessary seamer is designed to seam

the panel clips and the vertical legs of the panel together for weathertightness and resistance to wind uplift loads.

Rental or purchase of the Seam-Loc 24 mechanical seamer and hand crimpers for field seaming are the responsibility

of the installer. Mechanical seamers and hand crimpers can be aquired from Seamer Tools, Inc.

Phone No. (662) 895-1222.

Read the field manual that is enclosed in the case with the seamer. The operator should adhere to all instructions for

proper use of the seamer. Failure to follow the required instructions may result in damage to the panel and/or seamer.

Metal Sales Manufacturing Corporation will not be responsible for damage incurred by improper use of the seamer.

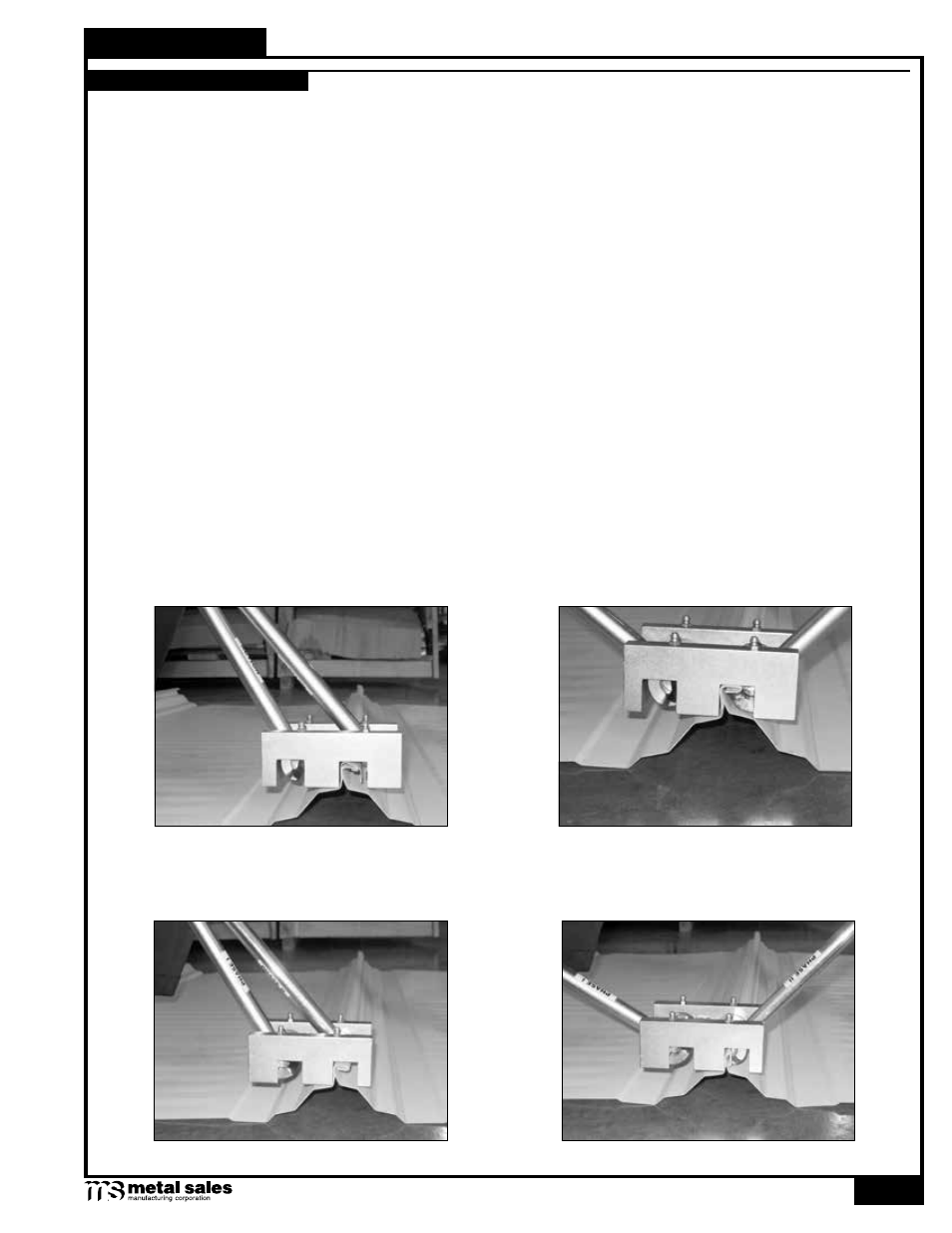

STEP 2 - Required hand Crimping only at the START END of the panel to be seamed:

Place the “Phase 2” slot onto the open side of the panel rib at the very end of the panel to be seamed, and engage the handle to

a fully closed condition as shown. Hand crimp only the first 3-4 inches. Do not use “Phase 2” slot at a clip condition prior to

using the Electric Seamer.

Preparation Notes:

1. Check to insure all components are in the shipping container: Electric Seamer, Handle Assembly, and Hand Crimper.

2. Run sufficient power to the roof to operate the seamer. Follow OSHA and local electrical codes.

3. Clean and remove all construction debris to avoid damage.

4. Panels MUST be hand crimped 6-8 inches per Step 1 at the start end of each panel row and endlaps. Metal Sales

recommends panels be seamed as soon as possible to prevent wind damage.

5. If panels are installed from left to right (looking from eave to ridge), electric seamer will run down slope from ridge to eave.

6. Read instructions completely and then check roof system for proper installation. Prior to seaming panels check all seams

making sure they are properly engaged. All dirt, debris, and excess sealant should be removed from flat part of panel and

seams

.

STEP 1 - Required Hand Crimping Before Seaming:

Begin at the seaming start end of the panel. Place the “Phase 1” slot of the hand crimper over the panel rib with the “Phase 1”

handle on the open side of the panel rib. Engage the tool to a fully closed position. Hand crimp the first 6-8 inches. In high wind

situations, Step 1 can be done at clip locations to hold panels in place until electric seamer is used. Make sure hand crimper

does not flatten rib of panel. Step 1 should also be applied at all endlap conditions.

NOTE: Step 1 should be applied at each panel clip location if you are NOT going to run the mechanical seamer after you apply

each panel. Metal Sales recommends that panel ribs be mechanically seamed before the end of each working day.