Troubleshooting – Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 40

PAGE 40

SP684 SuRFACE ShARK SuRFACE PLANER

FIGuRE 50

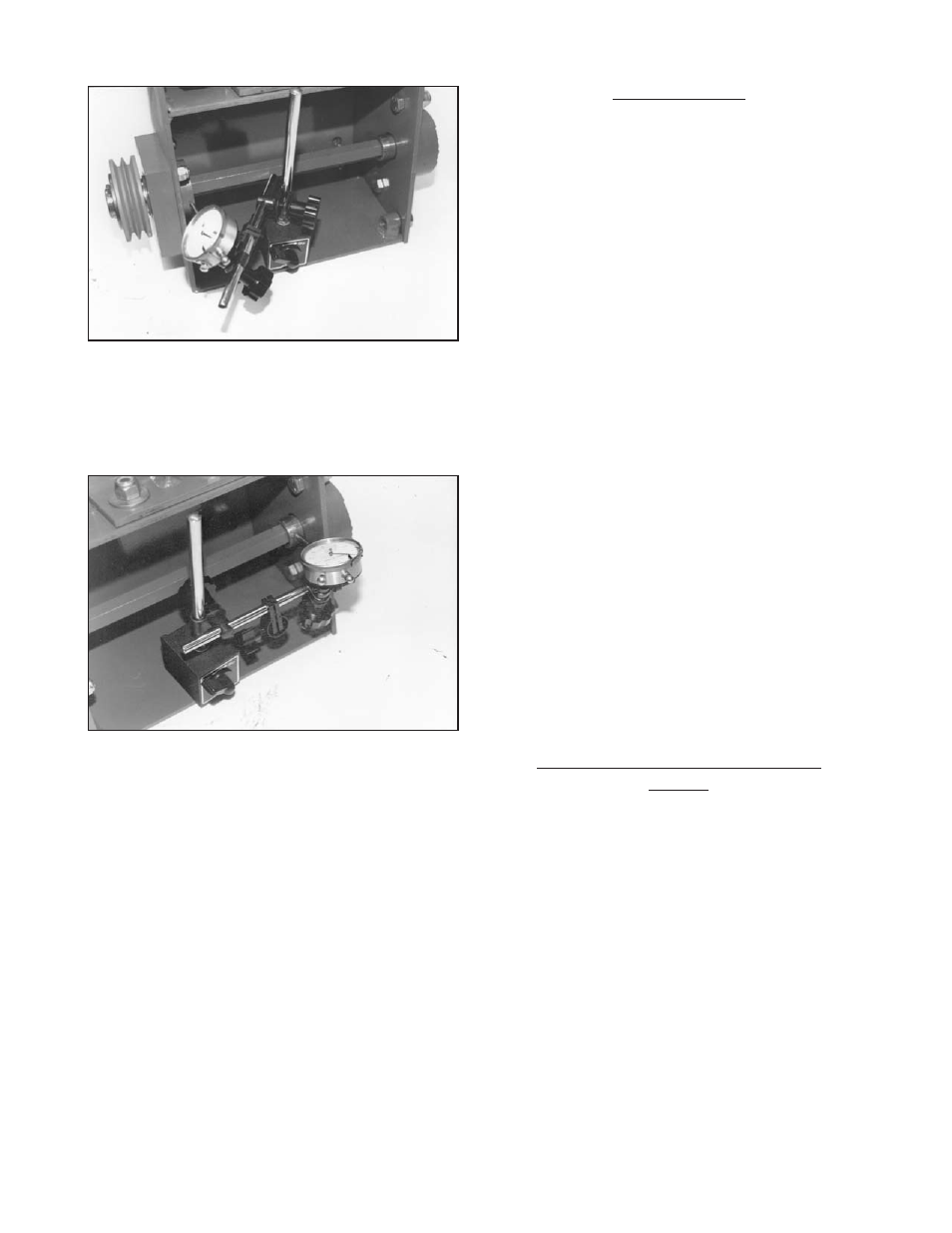

b) Position the dial indicator to measure run out on

the internal hexagon bushing of the outboard bearing.

Maximum run out (as measured by the dial indicator

gauge) is + - .015 inches (.381 mm). FIGuRE 51.

FIGuRE 51

6) Run out measurements that exceed these limits

may suggest that the driveshaft is bent. A bent

driveshaft will accelerate bearing wear and failure while

contributing to uneven flail cutting action. under certain

circumstances, a bent driveshaft can be removed and

straightened in an arbor press. See the SERvICE

section for specific information pertaining to replacing

the driveshaft. If the straightened driveshaft still exceeds

the established run out limits after re-assembly, it must

be replaced with a factory approved, replacement

part.

ENGINE SERVICE

Application: SP684 SURFACE SHARK

Consult the material supplied by the engine

manufacturer for specific service and maintenance

information regarding:

1) muffler

2) spark plug

3) air filter system

4) carburetor adjustment

5) ignition system

6) short and long term storage

7) maximum governed engine speed

8) emission standards

Keep this information stored with the operator Manual

for the Surface Planer so it will always be available for

use when the engine requires service or maintenance.

A properly maintained engine will add considerably to

the service life and overall productivity of the Surface

Planer.

because the planing process produces high levels

of random vibration, it is essential that the maximum

governed engine speed be checked at regular,

established intervals. Excessive engine speed can

produce vibration induced forces that can dramatically

affect component service life. Stress related cracking

and resulting failure to mufflers, blower shrouds,

belt guards and other components can result from

excessive engine speed.

TROUBLESHOOTING

ENGINE

Application: SP684 SURFACE SHARK

ENGINE FAILS To START

Ignition switch in oFF or cut off position. Place switch

in the oN position or move throttle control lever to the

ignition operational position.

Incorrect carburetor/fuel injection system adjustment.

See Service section.

Air filter blocked. See SERvICE section.

Ignition wire to spark plug loose or disconnected.

Re-connect.

Fuel supply exhausted. Refill the fuel tank.