Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 21

SP684 SuRFACE ShARK SuRFACE PLANER

PAGE 21

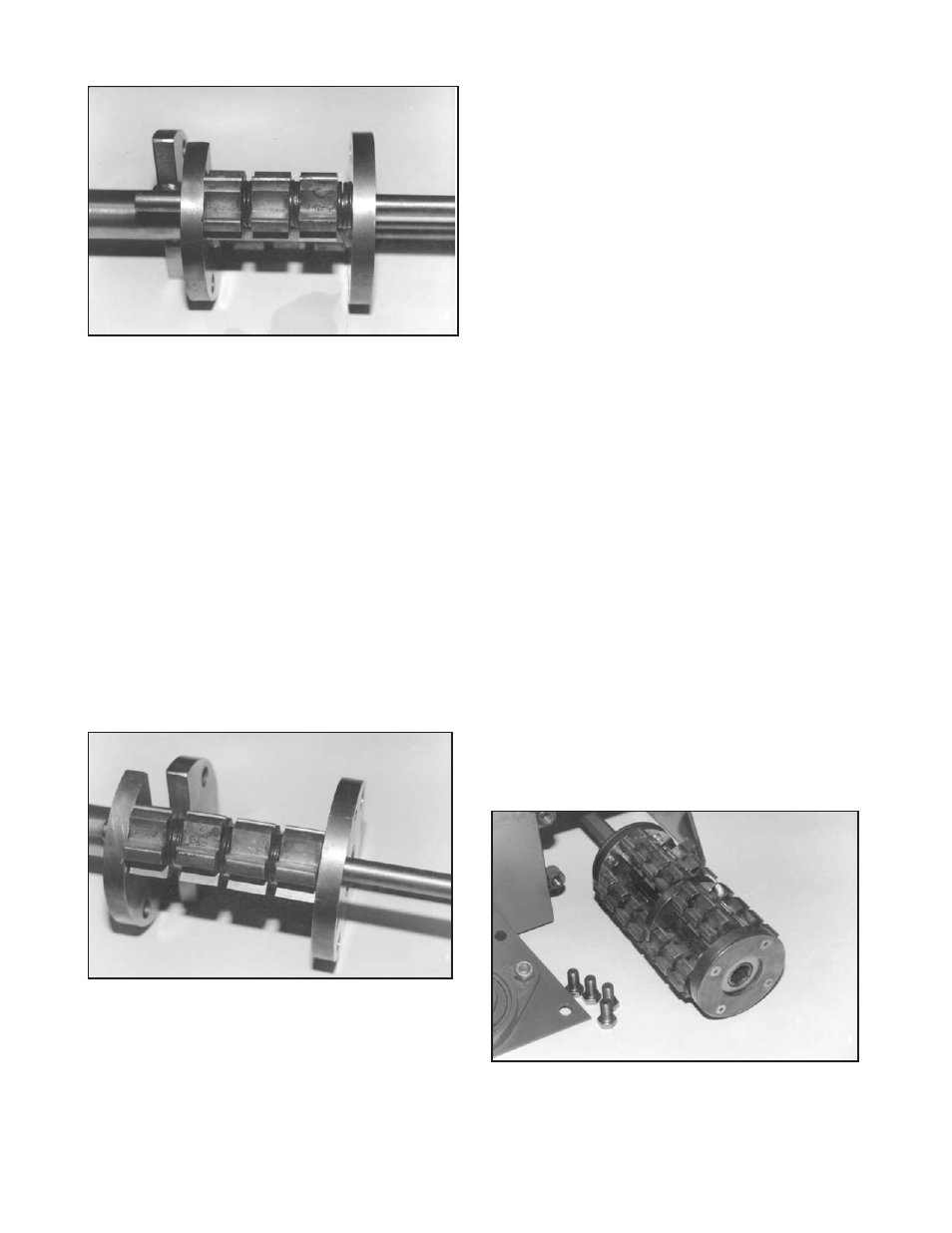

FIGuRE 18

2) Install a flail next to the outside side plate of the wide

section. Next, install two spacer washers. Follow with a

flail and two spacer washers. Install another milling flail

followed by three spacer washers. Finally, install the

remaining flail and one spacer washer. The tungsten

carbide inserts must be installed to form the same,

continuous planing surface as in Step 1. FIGuRE 19.

3) Milling flails can also be installed on the drum

without the use of spacer washers.

General Notes Regarding the Installation of Flails:

1) because of variance in material thicknesses and

manufacturing tolerances, the specified number of

spacer washers may not always fit within the narrow

and wide sections. If this occurs, grinding a spacer

washer to reduce its thickness is an option.

FIGuRE 19

Exercise caution when grinding a spacer washer to

reduce its thickness. Wear safety eye wear and other,

appropriate safety apparel to minimize the potential for

personal injury.

2) Flails require sufficient free play to allow them to

properly impact the work surface material. If the flails

fit too tight on the drum, inconsistent material removal

and accelerated flail wear will result. The formation of

rust between the flail and spacer washer surfaces will

affect proper free play. Excessive free play can also

accelerate the wear of flails and rods. As a general

rule, flails should be free to rotate by hand after

being installed on the drum. If this is not possible,

the flails should be disassembled and additional free

play provided by reducing the thickness of a spacer

washer.

3) All flails are bi-directional in design with the exception

of the milling flail. That is, there is no forward or reverse

orientation on the drum. Fail service life can sometimes

be extended by reversing their orientation on the

driveshaft. The effect is similar to rotating tires on an

automobile.

4) As the name implies, the tungsten carbide inserts

of the milling flail cut the work surface material with an

action very similar to that of a machine tool cutting steel.

The brittleness of the tungsten carbide insert requires

that it be fully supported to minimize breakage. This

requires a substantial flail body to provide the necessary

support. The resulting configuration makes the milling

flail one directional in design. This limitation requires

the operator to install a loaded drum on the driveshaft

with the tungsten carbide inserts facing the direction

of rotation. FIGuRE 20. If the tungsten carbide inserts

face opposite to the direction of rotation, improper

milling action and accelerated flail wear will occur.

FIGuRE 20