Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 32

PAGE 32

SP684 SuRFACE ShARK SuRFACE PLANER

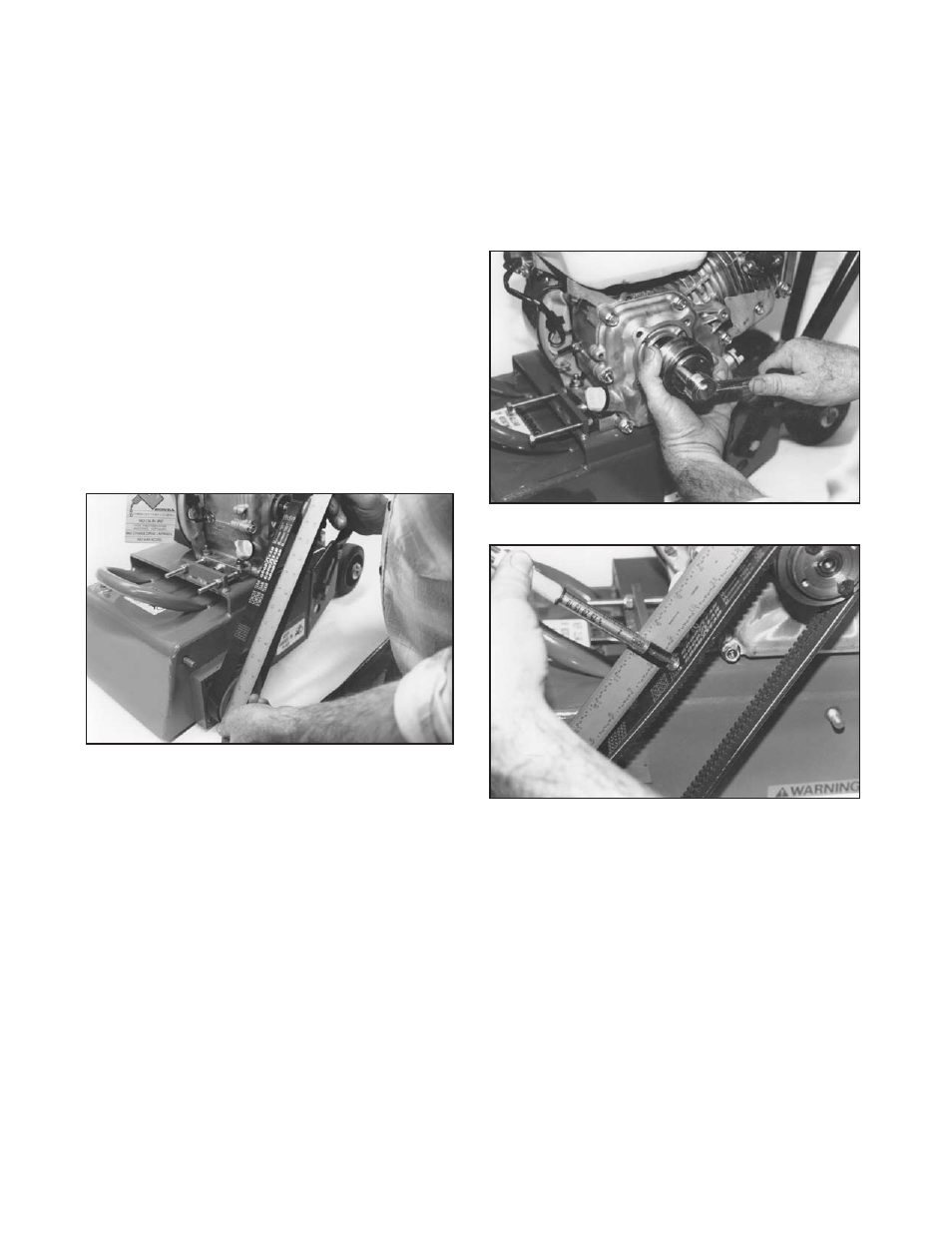

If engine crankshaft/electric motor pulley alignment

needs to be adjusted, proceed as follows:

a) using the 7/16 inch wrench, remove the two 1/4 inch

diameter cap screws from the engine pulley bushing.

b) Insert the cap screws into the tapped holes in the

bushing flange. Tighten progressively until the bushing

disengages from the pulley.

c) Insert the 1/4 inch diameter cap screws into the

tapped holes in the pulley. Tighten progressively until

the bushing applies tension to the pulley.

d) using the straightedge for reference alignment

purposes, tap the engine/electric motor pulley/bushing

into proper position.

e) Tighten the 1/4 inch diameter cap screws

progressively with the torque wrench to 95 inch

pounds. FIGuRE 33.

FIGuRE 32

f) Recheck alignment as outlined per the beginning of

Step 8.

9) Apply increased belt tension by progressively

tightening the take-up cap screws against the engine

crankcase/electric motor thrust plate.

a) Recheck v-belt alignment.

b) Check belt tension with the spring scale or belt

tension tool midway between the engine/electric motor

and driveshaft pulleys. belt deflection should measure

approximately 3/16 inch (4.8 mm) at 3-7/8 to 5-1/2

pounds (1.8 to 2.5 kg) force. FIGuRE 34.

c) If belt tension and alignment is within specifications,

torque the engine/electric motor attachment cap screws

to 20 ft lbs (27 Nm.)

d) Recheck v-belt tension and alignment.

10) Install the belt guard to the main frame. Install the

flat washers and self-locking hexagon nuts. Torque

the nuts to 35 ft lbs (47 Nm.). Determine that all

safety related decals affixed to the belt guard are fully

readable. If any decal is not fully readable, replace with

a factory approved, replacement part only.

FIGuRE 33

FIGuRE 34

11) If the Surface Planer is powered by an engine,

reconnect the engine spark plug wire. If powered

by an electric motor and the machine is to be used

immediately, reconnect the extension cord or Surface

Planer to the power source. Determine that the oN/

oFF switch located on the operator handle is in the

oFF position.