Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 17

SP684 SuRFACE ShARK SuRFACE PLANER

PAGE 17

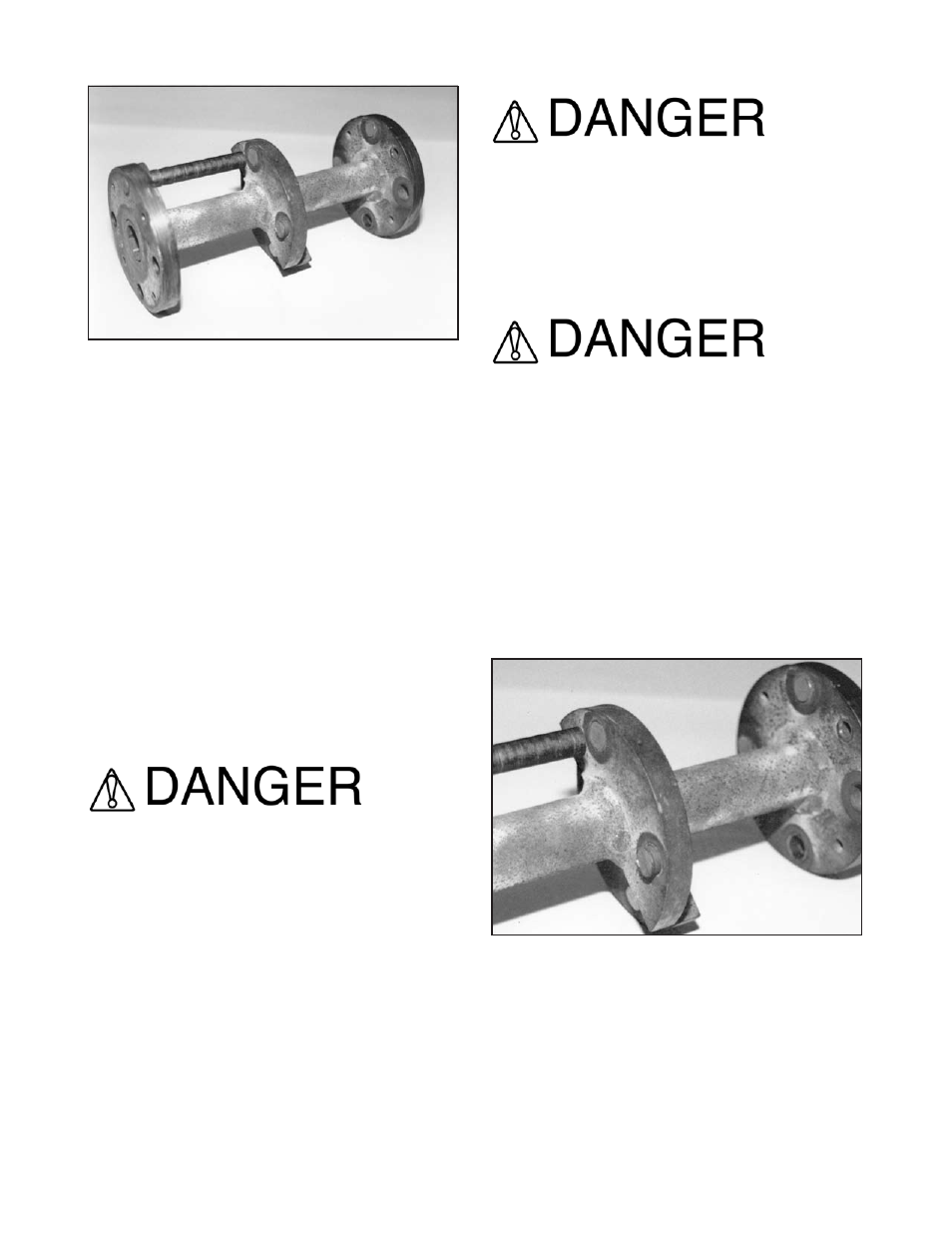

FIGuRE 8

2) Mixing both worn and new flails on the drum. Proper

flail action against the work surface material requires

that the flails be of the same, approximate dimensions.

Flails with various inside and outside dimensions will

not impact the work surface material with the same

intensity and deliver the same results. Flail rod wear

is directly proportional to the amount of force it must

supply against each, individual flail. When a rod can

no longer supply adequate force against the flails,

it will break, allowing the flails to be hurdled against

the inside of the Surface Planer frame. The more

aggressive flails require greater forces to keep them

contained on the rod. These forces, in turn, create

faster and/or uneven rod wear rates.

because flail drum rods are a critical component of the

actual planing process, it is important that each rod

be inspected on a regular basis to determine proper

structural integrity.

INSPECT EACH FLAIL DRUM ROD ON A

REGULAR INTERVAL TO DETERMINE PROPER

STRUCTURAL INTEGRITY. USAGE RATES

AND OTHER OPERATING PARAMETERS WILL

DETERMINE PROPER INTERVAL RATES. IF

THERE IS ANY QUESTION REGARDING THE

VISUAL STRUCTURAL INTEGRITY OF A DRUM

ROD, PROPERLY DISCARD AND REPLACE IT

WITH AN APPROVED, FACTORY REPLACEMENT

PART ONLY.

THE MINIMUM ALLOWABLE DRUM ROD

DIAMETER IS 3/8 INCH AS MEASURED ALONG

ANY PART OF ITS CIRCUMFERENCE AND/OR

LENGTH. ANY DRUM ROD NOT MEETING THIS

MINIMUM DIMENSION STANDARD SHOULD BE

PROPERLY DISCARDED AND REPLACED WITH

AN APPROVED, FACTORY REPLACEMENT PART

ONLY.

UNDER NO CIRCUMSTANCE IS WELDING AND/OR

ANY OTHER TYPE OF METAL BUILD-UP PROCESS

ALLOWED TO BE PERFORMED ON A WORN DRUM

ROD. TYPICAL MAINTENANCE TECHNIQUES

CAN ALTER THE ORIGINAL HEAT TREATMENT

PROCESS AND COMPROMISE THE STRUCTURAL

INTEGRITY, RESULTING IN PROPERTY DAMAGE

AND/OR PERSONAL INJURY.

on occasion, it may be necessary to remove severely

worn drum rods from the flail drum by the use of a band

saw or similar device. FIGuRE 9. Proper preventative

maintenance and operational procedures will minimize

these occurrences.

FIGuRE 9