Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 19

SP684 SuRFACE ShARK SuRFACE PLANER

PAGE 19

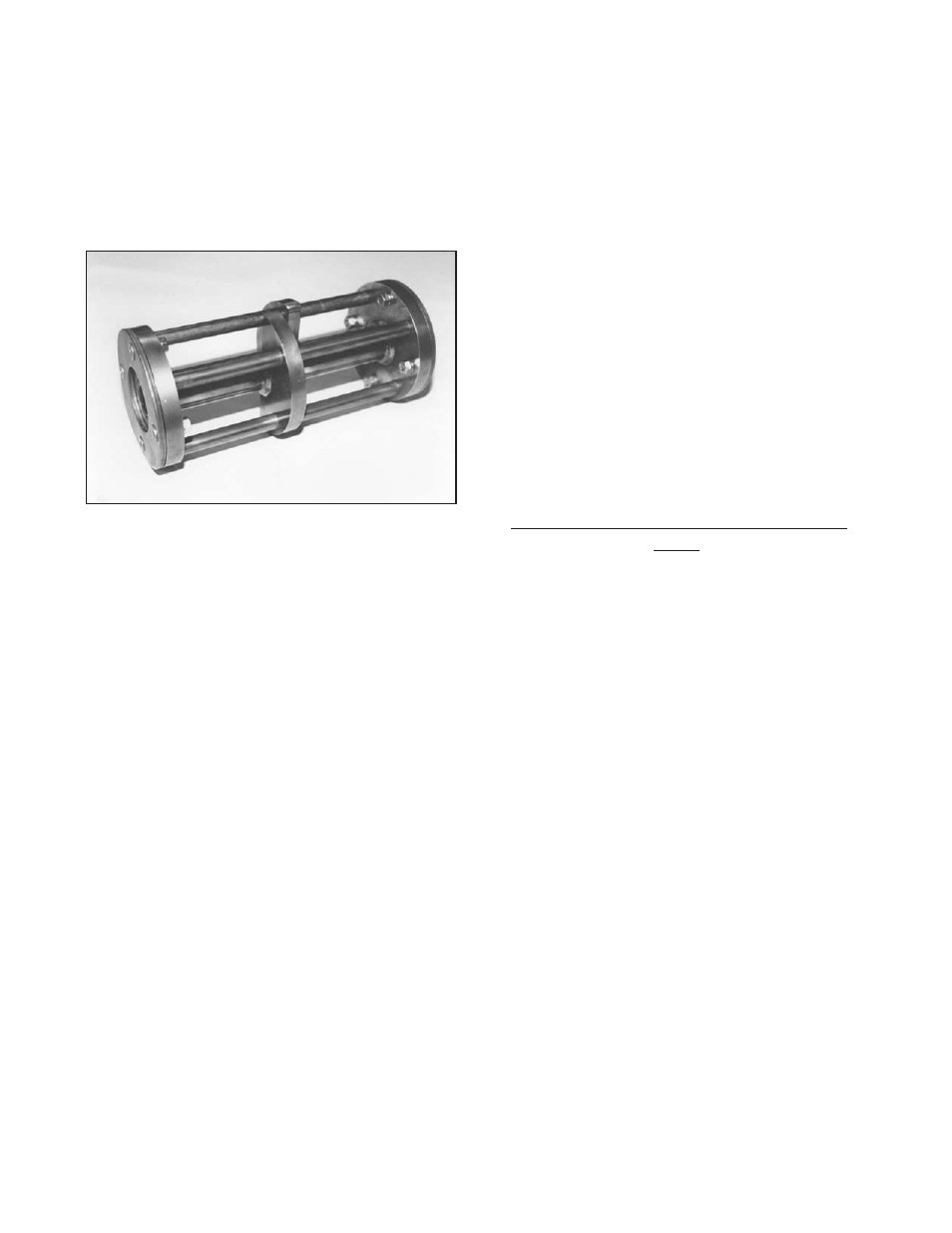

The most widely used drum is of the two section

design. FIGuRE 13. It incorporates two half sectioned

side plates that are positioned on the center shaft to

facilitate optimum flail spacing. The half side plate

sections also provide additional stability and structural

rigidity for the drum rods. The two section drum can

accommodate the use of all flail designs while meeting

the most demanding job applications.

FIGuRE 13

General Notes Regarding Flail Drums:

1) Flail drum rods are held in position by end caps and

related fasteners. The end caps are heat treated to

extend their service life.

2) The countersunk Allen head capscrews are retained

to the flail drum by both self locking, hexagon head

nuts and lock washers. The lock washers provide

additional redundancy while eliminating open, exposed

threads that can become worn or damaged from field

use. A countersunk Allen head capscrew was chosen

over a conventional hexagon head capscrew to

eliminate anticipated wear. Component wear would

substantially increase the difficulty of disassembling

drum components in the field. before removing

these capscrews, clean the internal hexagon with an

appropriate tool to help facilitate their removal.

3) Flail rods are not intended to rotate in the drum

assembly while the Surface Planer is in operation.

Severe operation can cause the drum plates to wear

and elongate. Drum rods are also subject to wear and

elongation. If the total amount of wear is not severe,

various types of high strength, anaerobic adhesives

can be utilized to secure the rods to the drum. Severe

component wear is always an immediate reason to

reject either the rods and/or drum and replace with

factory approved, replacement parts.

4) Regularly inspect the drum for excessive wear and

signs of fatigue. Random vibration caused by the

planing process is difficult, if not impossible, to fully

predict. Component service life is impossible to predict.

Work surface materials, operator techniques and

general maintenance are also contributing factors that

will limit the service life of the drum and/or components.

If there is any question regarding the structural integrity

of a drum or any component, properly discard and

replace with factory approved, replacement parts.

5) It is advisable to always have a minimum of

one spare, loaded drum available to increase job

site productivity and reduce down time. Replacing

worn flails is a job that can require from only a few,

short minutes to even hours for extremely worn and

damaged components. Replacing a drum on the

driveshaft can usually be accomplished in a matter

of a few minutes. It is a common practice to replace

worn flails during normal, unproductive time and keep

a number of loaded, replacement drums on the job site

to speed production rates.

INSTALLING FLAILS ON THE TWO SECTION

DRUM

All flails are assembled on the two section drum in

sequence patterns with the spacer washers. Spacer

washers provide for an overlapping effect of the flails

that produces consistent material removal from the

work surface.

Normal Installation Procedure (fine finish) for all

1/8 Inch Nominal Thickness Flails:

1) Install a flail next to the outside side plate of the

narrow section. Next, install a spacer washer. Follow

with a flail and continue the sequence until the section

is full. FIGuRE 14.