Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 22

PAGE 22

SP684 SuRFACE ShARK SuRFACE PLANER

Before installing the drum on the driveshaft, make

a close, visual inspection of the entire assembly.

Determine that all flails and spacer washers are

properly secured on the rods and that no loose flail

or spacer washer has slipped its position during

assembly. Flails and spacer washers can fall off

the rods during assembly and become dislodged

and unnoticed. When the loaded drum begins

rotating at high speeds, these components can

fly off the drum causing property damage and/or

personal injury.

INSTALLING A LOADED DRUM ON THE

DRIVESHAFT

Application: SP684 SURFACE SHARK

Tools required:

1 each, 3/4 inch wrench or equivalent

1 each, torque wrench, 85 ft lbs (115 Nm) capacity

with 3/4 inch socket

1) If the Surface Planer is powered by an engine,

disconnect the spark plug wire. If powered by an

electric motor, properly disconnect the extension cord

or Surface Planer from the power source.

2) Rotate the height adjustment lever located on the

operator handle counterclockwise to raise the Surface

Planer to its maximum height position above the work

surface.

3) using the wrench, remove the four (4) 1/2 inch

diameter x 1 inch long capscrews and flat washers

securing the drum access plate to the main frame.

4) Remove the drum access plate from the driveshaft.

5) Clean and remove any excessive material build-up

from the threaded bosses and surrounding areas.

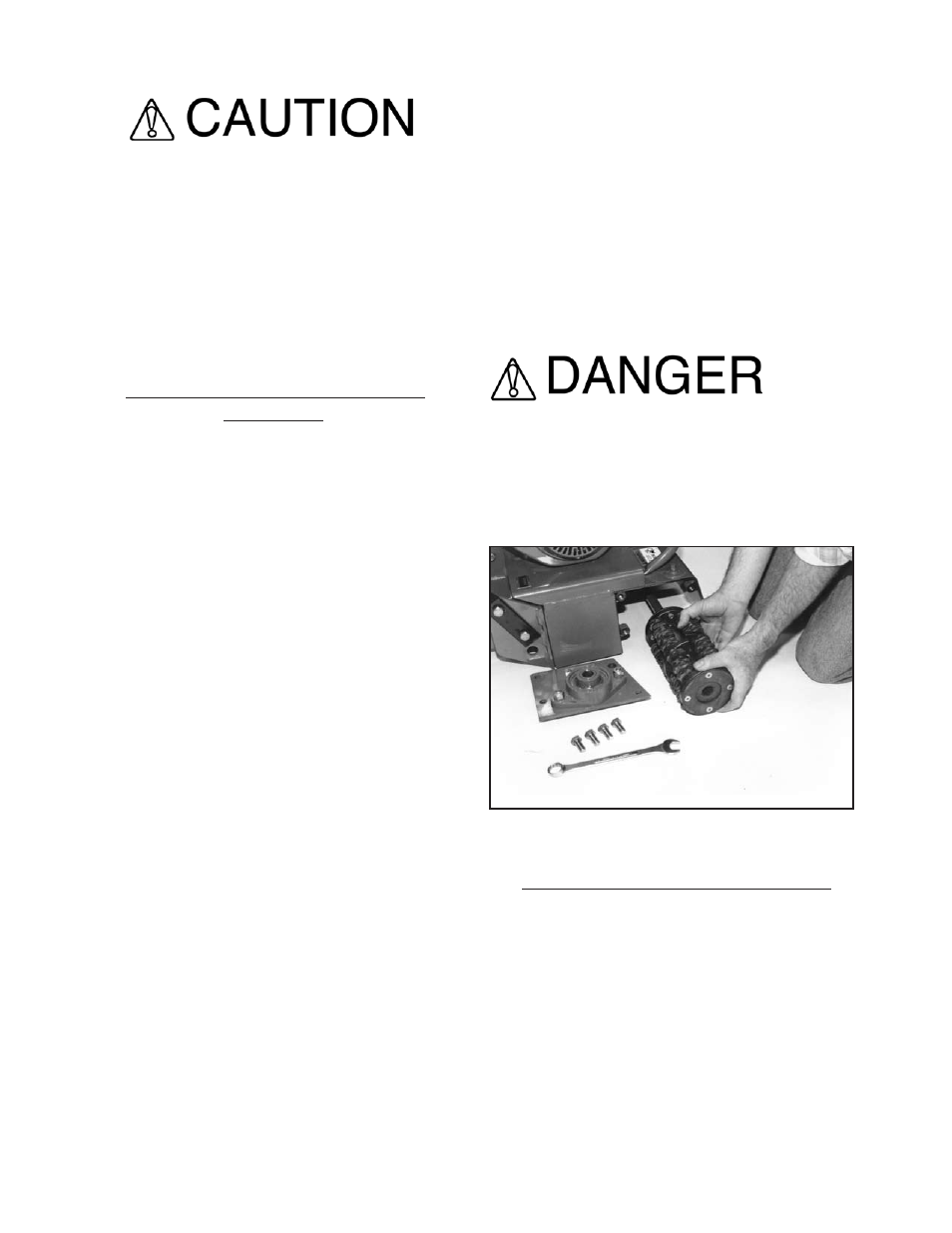

6) Install the loaded flail drum on the driveshaft. If

utilizing the milling flails or other flail configurations that

are unidirectional, determine that the flails are facing

the direction of rotation. FIGuRE 21.

7) Install the drum access plate on the driveshaft. The

left, vertical side of the access plate should align tight

against the main frame.

8) Install the four 1/2 inch diameter x 1 inch long

capscrews and washers. Capscrews should install with

a minimal amount of resistance and related, alignment

problems. Torque the capscrews to 85 ft lbs (115

N.m). No lockwashers or similar devices are required.

9) If the Surface Planer is powered by an engine,

reconnect the engine spark plug wire. If powered

by an electric motor and the machine is to be used

immediately, reconnect the extension cord or Surface

Planer to the power source. Determine that the oN/

oFF switch located on the operator handle is in the

oFF position.

UNEXPECTED MACHINE START UP CAN RESULT

IN PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

10) Removing a loaded drum from the driveshaft is

accomplished by reversing the above steps.

FIGuRE 21

TRANSPORTING THE SURFACE PLANER

Application: SP684 SURFACE SHARK

The Surface Planer has an operational weight that

prohibits one person from loading and/or unloading it

alone by conventional, physical efforts.