Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 38

PAGE 38

SP684 SuRFACE ShARK SuRFACE PLANER

threaded area before applying the lubricant. Do not

lubricate the threads with any type of grease material.

Grease will attract foreign material accumulations that

can accelerate component wear. Place the rubber boot

in its original location and tighten the retaining clamp.

Do not operate the Surface Planer without the protective

rubber boot in its intended location. operation without

the rubber boot or a boot in an improper position will

accelerate component wear by allowing materials

to accumulate in the screw thread area of the crank

handle.

ALIGNING THE CASTER WHEELS

Application: SP684 SURFACE SHARK

Tools Required:

1 each, 16 inch minimum length straightedge

2 each, 3/4 inch wrenches

1 each, torque wrench, 85 ft lbs (115 Nm.) capacity

with 3/4 inch socket

1 each, 6 inch scale

Proper front and rear caster wheel alignment is essential

to produce an even cutting action by the flails. With

use, caster bearings and axles will eventually wear.

Excessive caster bearing and axle wear can contribute

to an uneven cutting action. In addition, a sharp blow

delivered to the Surface Planer (eg; being dropped to

the surface from off a truck) can also affect the caster

wheel alignment.

Caster wheels are aligned during assembly with

the use of a specially designed alignment jig.

However, satisfactory results can also be achieved

in the field by following steps:

1) Position the Surface Planer on a suitable work

surface. If the Surface Planer is powered by an engine

and the engine is not to be removed, fuel and oil must

be first drained from the fuel tank and crankcase. If

powered by an electric motor, disconnect the extension

cord or Surface Planer from the power source. The

normal position for aligning the caster wheels is with

the main frame perpendicular to the work surface.

Support the unit with proper blocking.

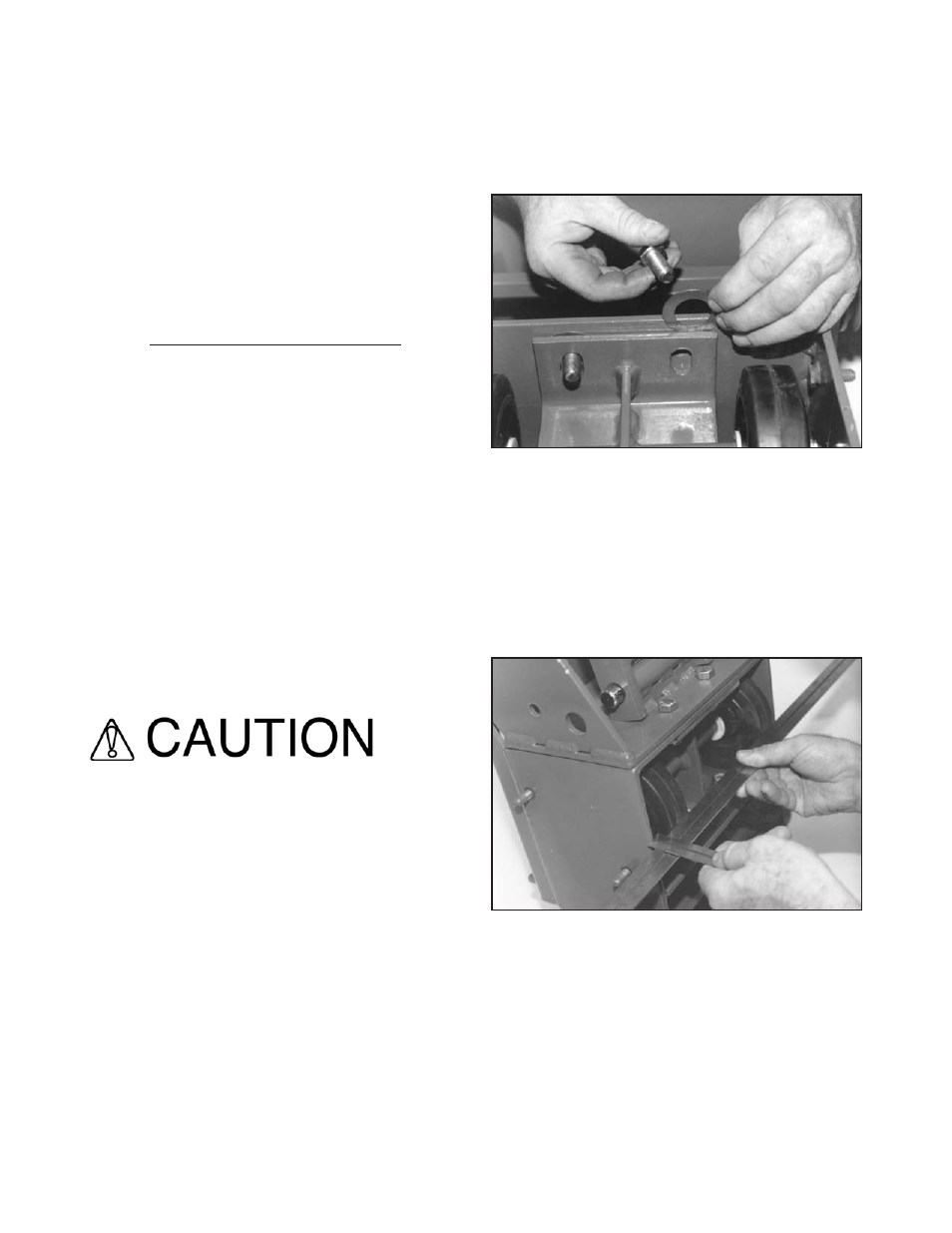

2) Shim washers of .015 inch (.381 mm) thickness

are sometimes utilized when fastening the front axle

assembly to the main frame. Install washers as

required. FIGuRE 46. The fasteners that attach the front

axle assembly should be tightened until slight tension

is applied. Always position the 1/2 inch flat washers

against the slots provided in the axle assembly.

FIGuRE 46

3) Position the front casters so that their faces extend

approximately 7/16 inch (11.1 mm) beyond the bottom

surface of the main frame. Caster wheels have a slight

curvature on their faces. The measurement should be

taken at the high point of the curvature, FIGuRE 47.

4) Push the rear casters towards the main frame until

the upper limit stop is encountered. FIGuRE 48.

FIGuRE 47

5) Place the straightedge between the front and rear

casters on the high point of the face curvature. Adjust

the front casters so that the gap between the straight-

edge and the bottom of the main frame is identical. This

gap figure is approximately 1/8 to 1/4 inch (3.17 to