Marshalltown SP684 SURFACE SHARK Surface Planer User Manual

Page 39

SP684 SuRFACE ShARK SuRFACE PLANER

PAGE 39

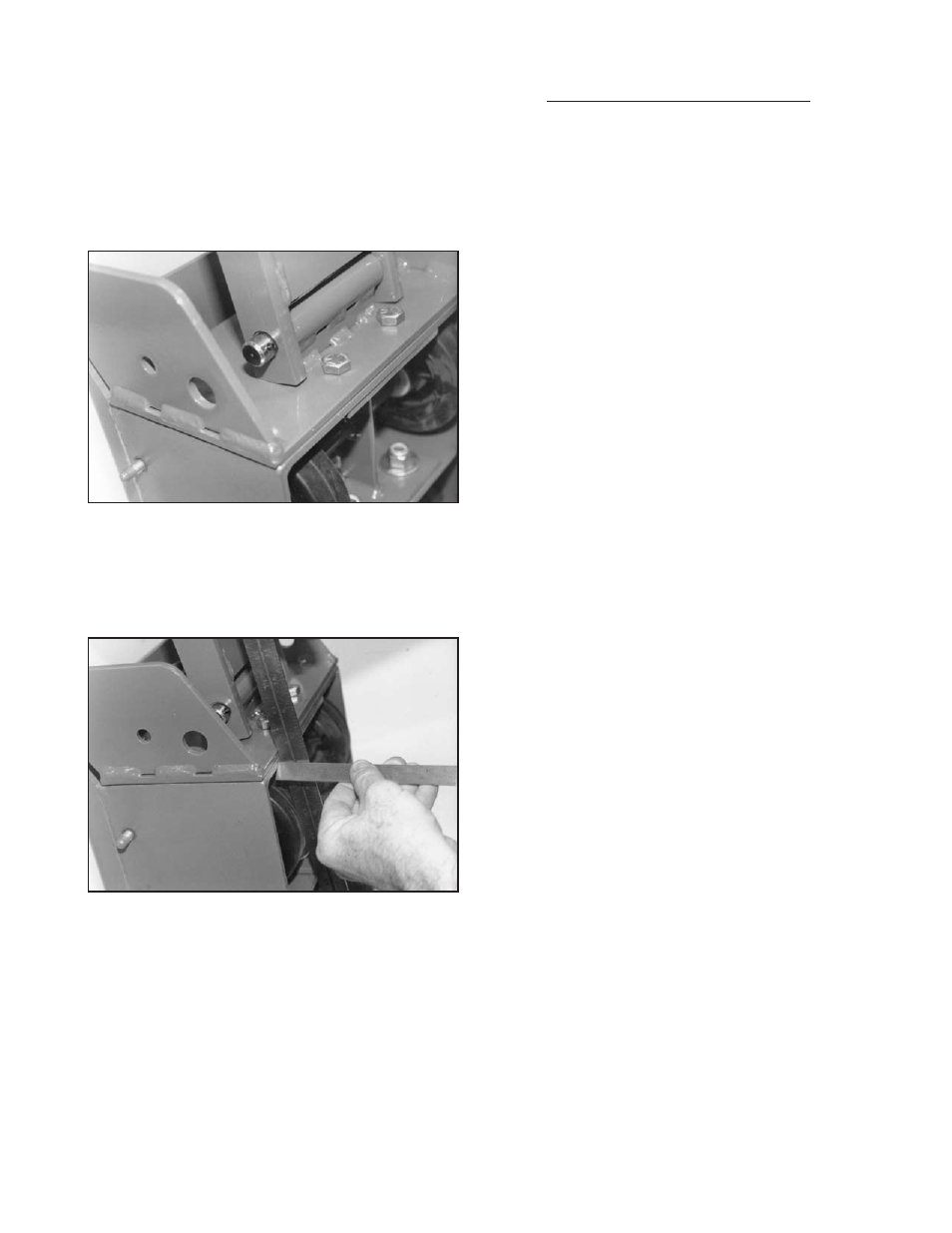

6.35 mm). It is important that the straightedge be

positioned on both sets of casters in the same relative

position on the caster faces. FIGuRE 49.

6) Tighten the fasteners with the torque wrench to 85

ft lbs (115 Nm.). The addition of clamps will minimize

any movement or location change while tightening the

fasteners.

FIGuRE 48

7) Repeat Step 5 to determine that alignment did not

change while tightening the fasteners. If alignment did

change, repeat Steps 2 thru 6 until satisfactory results

have been achieved.

FIGuRE 49

CHECKING DRIVESHAFT RUN OUT

Application: SP684 SURFACE SHARK

Tools Required:

1 each, 3/4 inch wrench

1 each, dial indicator and magnetic base

Parts Required:

1 each, Part# MNSP8-0241 driveshaft (if required)

Proper driveshaft run out limits are essential to produce

an even cutting action by the flails. Driveshaft run out

limits are measured with the use of a dial indicator for

accuracy.

1) Position the Surface Planer on a suitable work

surface. If the engine is not to be removed, fuel and

oil must be drained from the fuel tank and crankcase.

The normal position for checking driveshaft run out is

with the main frame perpendicular to the work surface.

Support the unit with proper blocking.

2) using the 3/4 inch wrench, remove the cap screws

that retain the access door to the main frame.

3) Clean and remove any excessive material build-

up from the threaded bosses and surrounding area.

Material build-up can affect the driveshaft run out.

4) Remove the flail drum and replace the access

door. Tighten the cap screws with the wrench until the

access door is secured.

5) Install the dial indicator with the magnetic base

attached to the main frame. Driveshaft run out can be

measured by the dial indicator at two locations:

a) Position the dial indicator to measure run out on

the driveshaft flange. Maximum run out (as measured

by the dial indicator gauge) is + - .010 inches (.254

mm). A worn flange surface may not allow an accurate

measurement to be taken. FIGuRE 50.