Installation, 2 electrical installation – Lenze SMD 0-25kW-4-0kW Basic I/O User Manual

Page 11

Lenze 13466185 EDBSW03 v5

9

Installation

3.2

Electrical installation

3.2.1

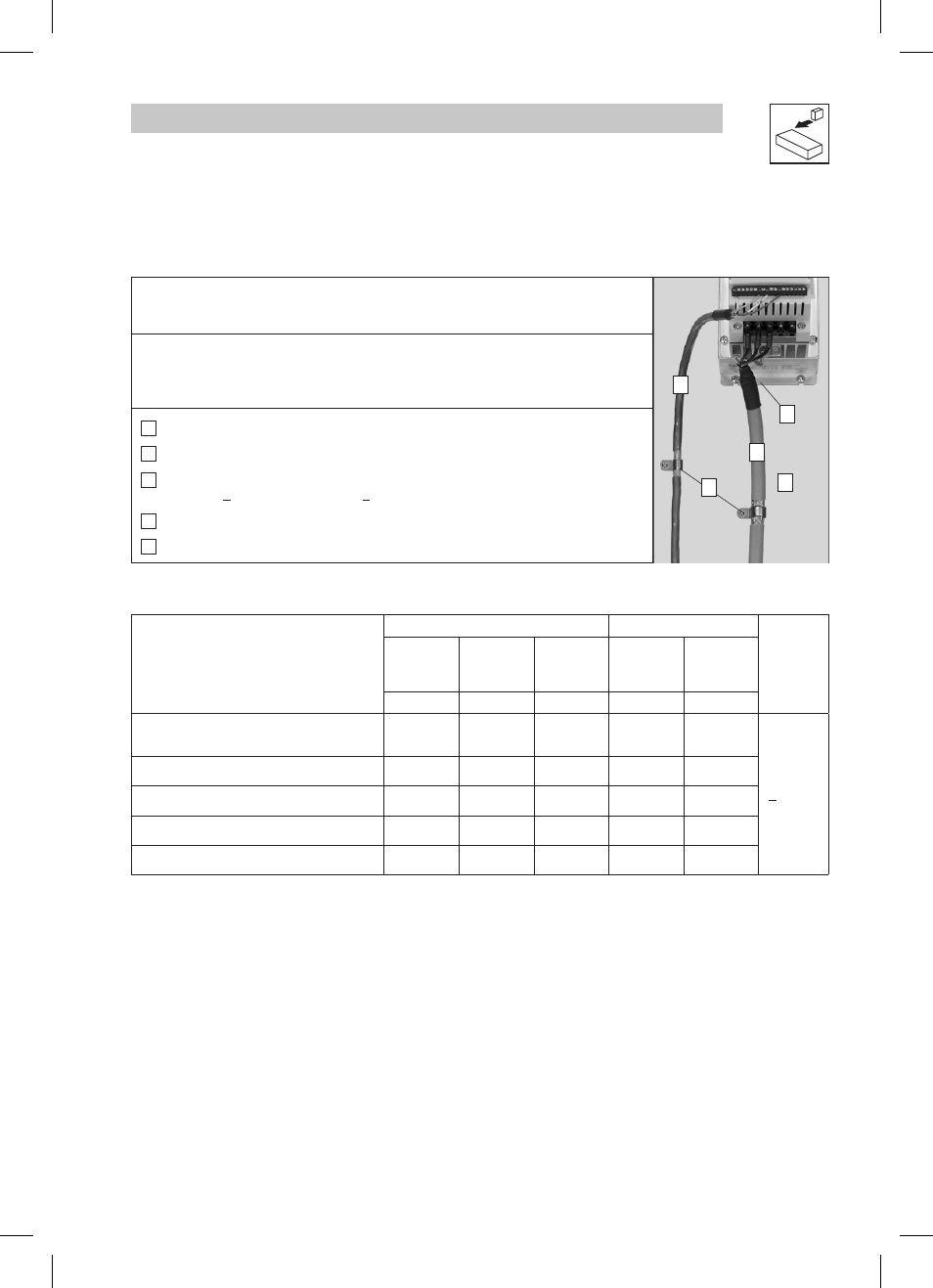

Installation according to EMC requirements

EMC

Compliance with EN 61800-3/A11

Noise emission

Compliance with limit value class A according to EN 55011 if installed in a control

cabinet with the appropriate footprint filter and the motor cable length does not

exceed 10m

A Screen clamps

B Control cable

C Low-capacitance motor cable

(core/core < 75 pF/m, core/screen < 150 pF/m)

D Electrically conductive mounting plate

E Filter (if required)

3.2.2

Fuses/cable cross-sections

Type

Installation to EN 60204-1

Installation to UL

E.l.c.b.

(2)

Fuse

Miniature

circuit

breaker

L1, L2/N,

L3, PE

Fuse

(3)

L1, L2/N,

L3, PE

[A]

[A]

[mm²]

[A]

[AWG]

ESMD251W2SFA … ESMD551W2SFA

ESMD371W2TXA … ESMD112W2TXA

10

C10

2.5

10

14

> 30 mA

ESMD152W2TXA

16

C16

2.5

12

14

ESMD751W2SFA, ESMD222W2TXA

16

C16

2.5

15

14

ESMD152W2SFA, ESMD302W2TXA

20

C20

4

20

12

ESMD222W2SFA, ESMD402W2TXA

25

C25

6

(4)

25

10

(1) Observe the applicable local regulations

(2) Pulse-current or universal-current sensitive earth leakage circuit breaker

(3) UL Class CC or T fast-acting current-limiting type fuses, 200,000 AIC, required. Bussman KTK-R,

JJN, JJS or equivalent

(4) Connection without end ferrules or with attached pin end connectors

Observe the following when using E.l.c.b:

•

Installation of E.l.c.b only between supplying mains and controller.

•

The E.l.c.b can be activated by:

−

capacitive leakage currents between the cable screens during operation (especially with

long, screened motor cables).

−

connecting several controllers to the mains at the same time.

−

RFI filters

Tmd005

B

C

D

A

E