3 holding brake, 3 maintenance operations, 1 blower – Lenze MDFQA Operating Instructions User Manual

Page 40: Holding brake, Maintenance operations, Blower, Maintenance/repair

Maintenance/repair

Maintenance operations

Holding brake

EN

40

Lenze ¯ BA 33.0006 ¯ 3.0

9.2.3

Holding brake

The brakes need to be checked on a regular basis to ensure safe and trouble−free

operation.

The necessary maintenance intervals primarily depend on the stress to which the brake

is subjected in an application. When a maintenance interval is being calculated, all

causes of wear must be taken into account (see notes "Wear on spring−applied brakes").

In the case of brakes which are subjected to low levels of stress, e.g. holding brakes with

emergency stop function, regular inspections at a fixed time interval are recommended.

In order to reduce the amount of work involved in maintenance, perform the inspection

at the same time as other maintenance work carried out cyclically on the machine if

possible.

If the brakes are not properly serviced, operating faults, production outages or damage

to machinery can occur. A maintenance concept adapted to the operating conditions

and the stresses to which the brakes are subjected must therefore be drawn up for every

application. For brakes, the maintenance intervals and servicing work listed in the

following table are necessary.

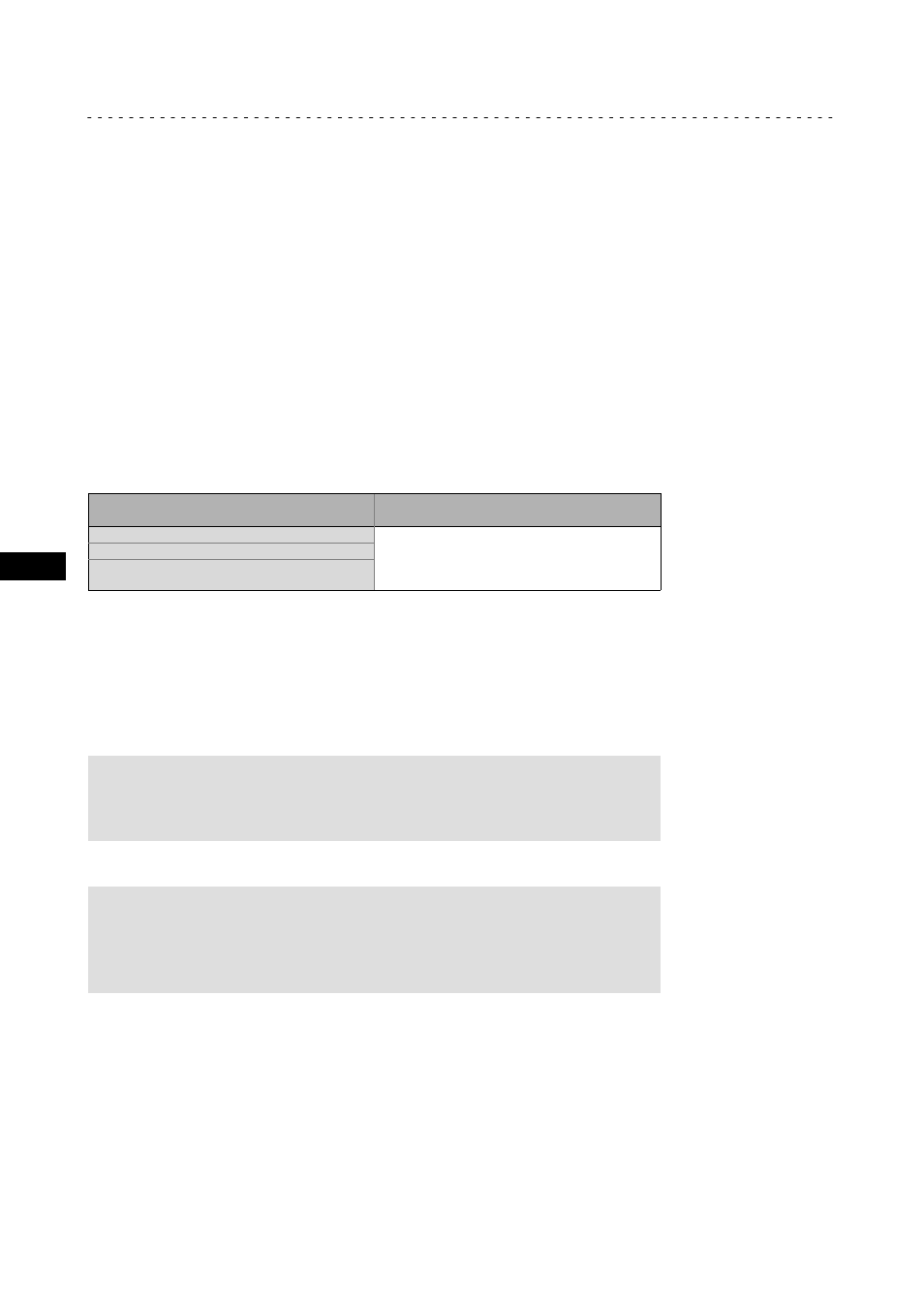

Maintenance interval for holding brake with

emergency stop

Maintenance work

At least every 2 years

Inspection of the brake integrated in the motor:

¯

Check ventilation function and

activation/deactivation

After 1 million cycles at the latest

Shorter intervals in the case of frequent emergency

stops!

The brakes of the MCS, MCA, MQA, and MD

LKS motors cannot be accessed from the

outside! (Maintenance work on the brakes must be carried out by Lenze Service staff

only!)

9.3

Maintenance operations

(

Stop!

¯ Make sure that no foreign bodies can enter the inside of the motor!

¯ Do not remove plugs when voltage is being applied!

}

Danger!

¯ Only work on the drive system when it is in a deenergised state!

¯ Hot motor surfaces of up to 150 °C. Observe cooling times!

¯ Remove loads acting on motors or secure loads acting on the drive!

9.3.1

Blower

If the motor is equipped with a dust protection filter, this filter must be cleaned or even

replaced at regular intervals depending on the amount of dust (if necessary, daily).

For motors equipped with a dry filter, the dust must be shaken out completely. If the

dust is wet, the filter mat must be replaced.