Mechanical installation – Lenze MDFQA Operating Instructions User Manual

Page 27

Mechanical installation

Holding brake (option)

Spring−applied holding brakes

EN

27

Lenze ¯ BA 33.0006 ¯ 3.0

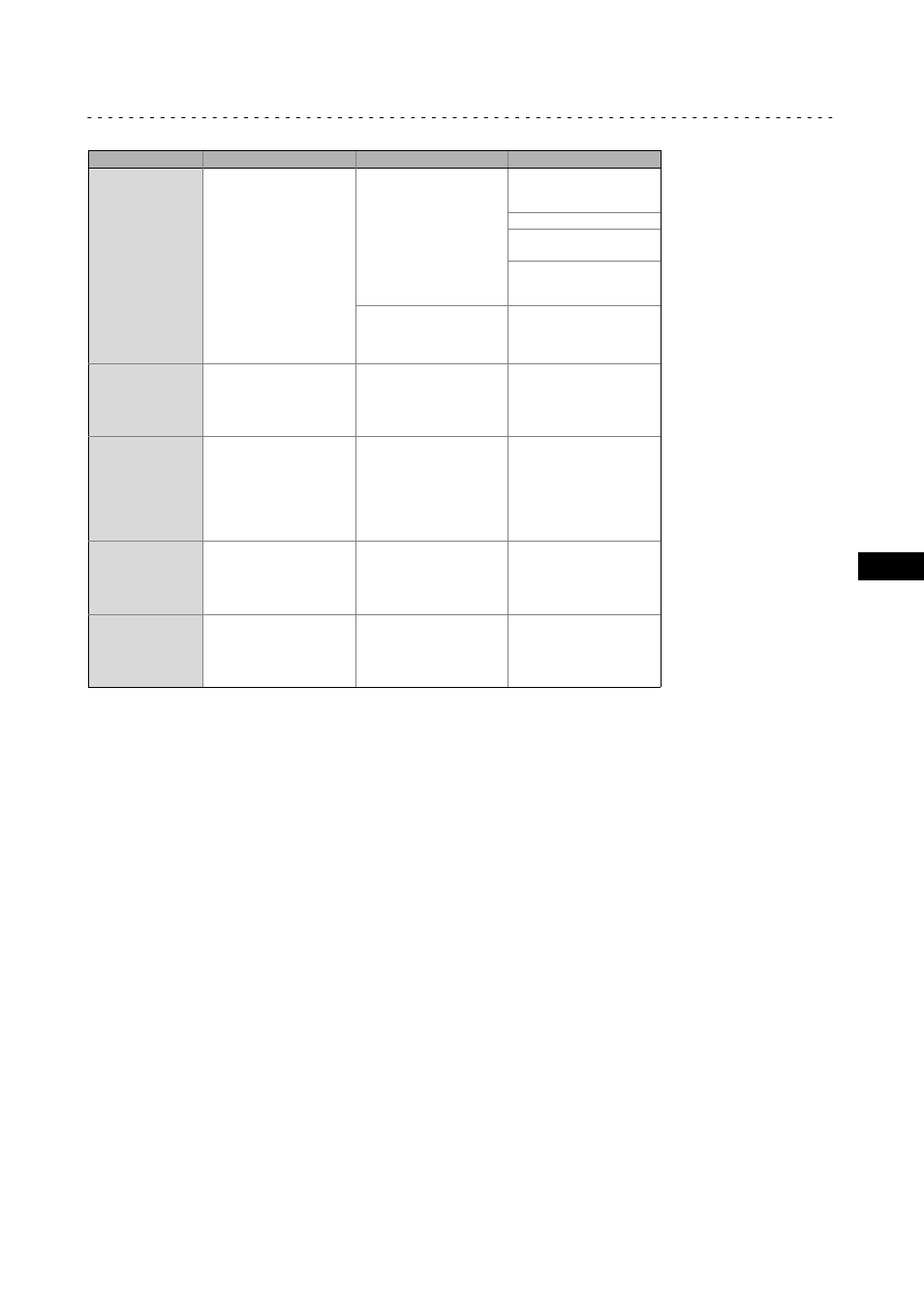

Component

Effects

Influencing factors

Cause

Friction lining

Wear on the friction lining Applied friction energy

Braking during operation

(impermissible, holding

brakes!)

Emergency stops

Overlapping wear when

the drive starts and stops

Active braking by the drive

motor with the help of the

brake (quick stop)

Number of start−stop

cycles

Starting wear if motor is

mounted in a position

with the shaft vertical,

even if the brake is open

Armature plate and

flange

Running−in of armature

plate and flange

Applied friction energy

Friction between the brake

lining and the armature

plate or flange e.g. during

emergency braking or

service brake operation

Teeth of the brake

rotor

Teeth wear (primarily at

the rotor end)

Number of start−stop

cycles,

Level of the braking

torque,

Dynamics of the

application,

Speed fins in operation

Relative movement and

impacts between brake

rotor and brake hub

Armature plate

bracket

Armature plate, cap screws

and bolts are deflected

Number of start−stop

cycles,

Level of braking torque

Load changes and impacts

due to reversal error

during interaction

between armature plate,

cap screws and guide bolts

Springs

Fatigue failure of the

springs

Number of switching

operations of the brake

Axial load cycle and

shearing stress on the

springs due to radial

reversing error of the

armature plate