Mechanical installation – Lenze MDFQA Operating Instructions User Manual

Page 25

Mechanical installation

Holding brake (option)

Permanent magnet holding brakes

EN

25

Lenze ¯ BA 33.0006 ¯ 3.0

Wear of permanent magnet brakes

If applied as directed (application as holding brakes), the permanent magnet brakes of

the servo motors are wear free and intended for long operating times. The wear on the

friction lining is due to e.g. emergency stops.

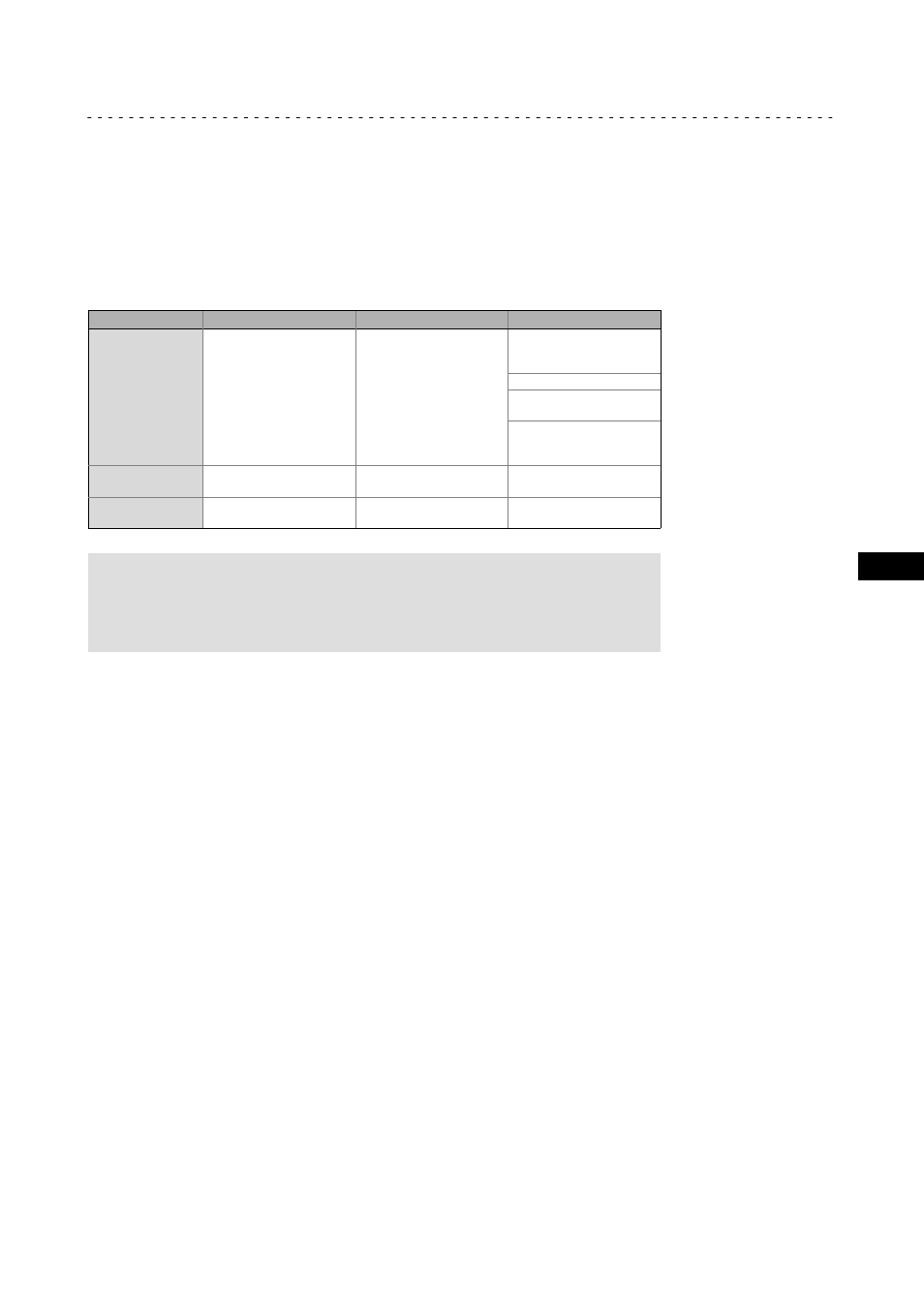

The table below describes the different reasons for wear and their impact on the

components of the permanent magnet brakes.

Component

Effects

Influencing factors

Cause

Friction lining /

friction surface at

the armature plate

and external pole

Wear on the friction lining Applied friction energy

Braking during operation

(impermissible, holding

brakes!)

Emergency stops

Overlapping wear when

the drive starts and stops

Active braking by the drive

motor with the help of the

brake (quick stop)

Springs

Fatigue failure of the

springs

Number of switching

operations of the brake

Axial duty cycle of the

springs

Permanent magnet Useless brake

Temperature, overvoltage Excessive overvoltages /

temperatures

(

Stop!

In case of wear above the maximum air gap (

, brake operating

instructions), application of the brake cannot be ensured. In this case, no

braking process is carried out.