Troubleshooting guide, Chapter 5 – Landoll 5211 Grain Drill User Manual

Page 73

5-1

Chapter 5

Troubleshooting Guide

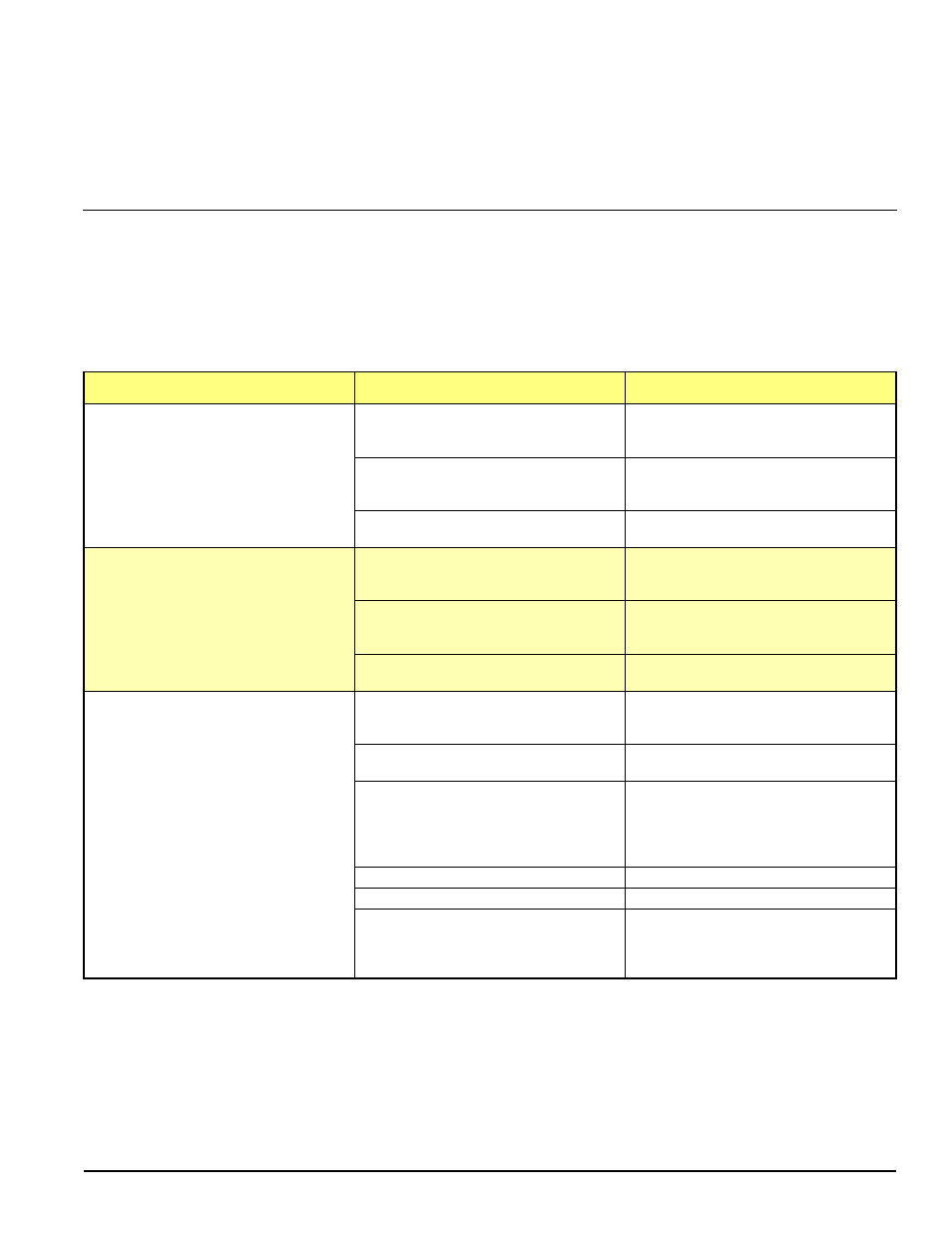

The Troubleshooting Guide, shown below, is included to

help you quickly locate problems that can happen using

your 5211 Grain Drill. Follow all safety precautions stated

in the previous sections when making any adjustments to

your machine.

PROBLEM

PROBABLE CAUSE

SOLUTION

PLANTING TOO DEEP

Incorrect depth

Adjust press wheel height (See “Opener –

Press Wheel Adjustment” on

page 4-26.)

Excessive down pressure

Reduce air system pressure on row units

(See “Air System Pressure” on

page 4-9.)

Drill not level front to rear, hitch too high

Adjust hitch height (See “Leveling the

PLANTING TOO SHALLOW

Incorrect depth

Adjust press wheel height (See “Opener –

Press Wheel Adjustment” on

page 4-26.)

Insufficient down pressure

Increase air system pressure on row units

(See “Air System Pressure” on

page 4-9.)

Drill not level front to rear, hitch too low

Adjust hitch height (See “Leveling the

UNEVEN SEED DEPTH

Row unit depth not set the same

Adjust press wheel height (See “Opener –

Press Wheel Adjustment” on

page 4-26.)

Drill not level front to rear

Adjust hitch height (See “Leveling the

Seed shallow in tire tracks

Adjust press wheel height and increase

down pressure (See “Air System

Pressure” on page 4-9 and “Opener

– Press Wheel Adjustment” on

page 4-26)

Excessive field speed

Reduce field speed.

Plugged seed tube

Clean seed tube.

Mud build up between opener blades

Adjust scraper (See “Opener Scraper

Adjustment” on page 4-27.) Adjust

blade pinch point (See “Opener Blade

Adjustment” on page 4-25.)