Hydraulic lift system, Figure 4-7: hydraulic leak detection, Warning – Landoll 5211 Grain Drill User Manual

Page 40

4-10

F-725-1213 Edition

OPERATION AND MAINTENANCE

Hydraulic Lift System

The Grain Drill is equipped with a hydraulic lift system to

raise and lower the unit from transport to planting

position.

WARNING

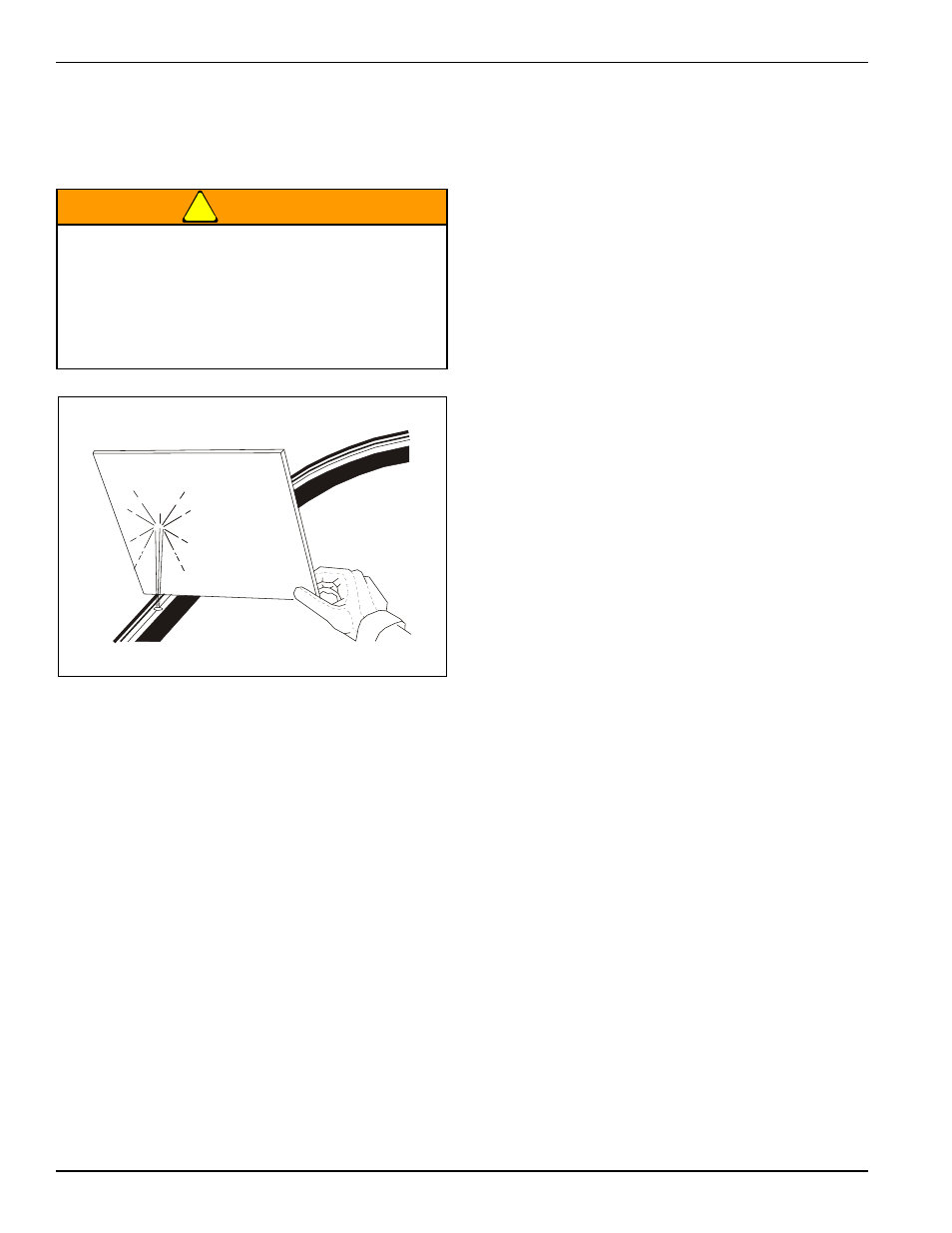

Figure 4-7: Hydraulic Leak Detection

1.

The hydraulic lift system contains cylinders plumbed

together.

2.

Before transporting make sure both lift cylinders and

hitch cylinders are fully extended for maximum

transport height.

3.

The Grain Drill can have both positive and negative

hitch weight. Attach the drill to the tractor before

attempting to raise or lower the drill hydraulically.

4.

Field Operation

a.

Before starting field operation, fully raise the drill

and remove transports locks (See “Transport

Locks” on page 4-4.)

b.

Lower the drill completely when planting to

insure consistent depth.

c.

Raise the drill when making sharp turns to

prevent side load/damage to the openers.

d.

Never back up the Grain Drill with the openers in

the ground. This can plug and possibly damage

the openers. Always fully raise the drill before

backing.

e.

Fully raise the drill and install the transport locks

before transporting or working beneath the drill

(See “Transport Locks” on page 4-4.)

Escaping hydraulic fluid can cause serious

personnel injury. Relieve system pressure before

repairing, adjusting, or disconnecting. Wear

proper hand and eye protection when searching

for leaks. Use cardboard instead of hands (See

Figure 4-7.) Keep all components (cylinders,

hoses, fittings, etc.) in good repair.

d5842a