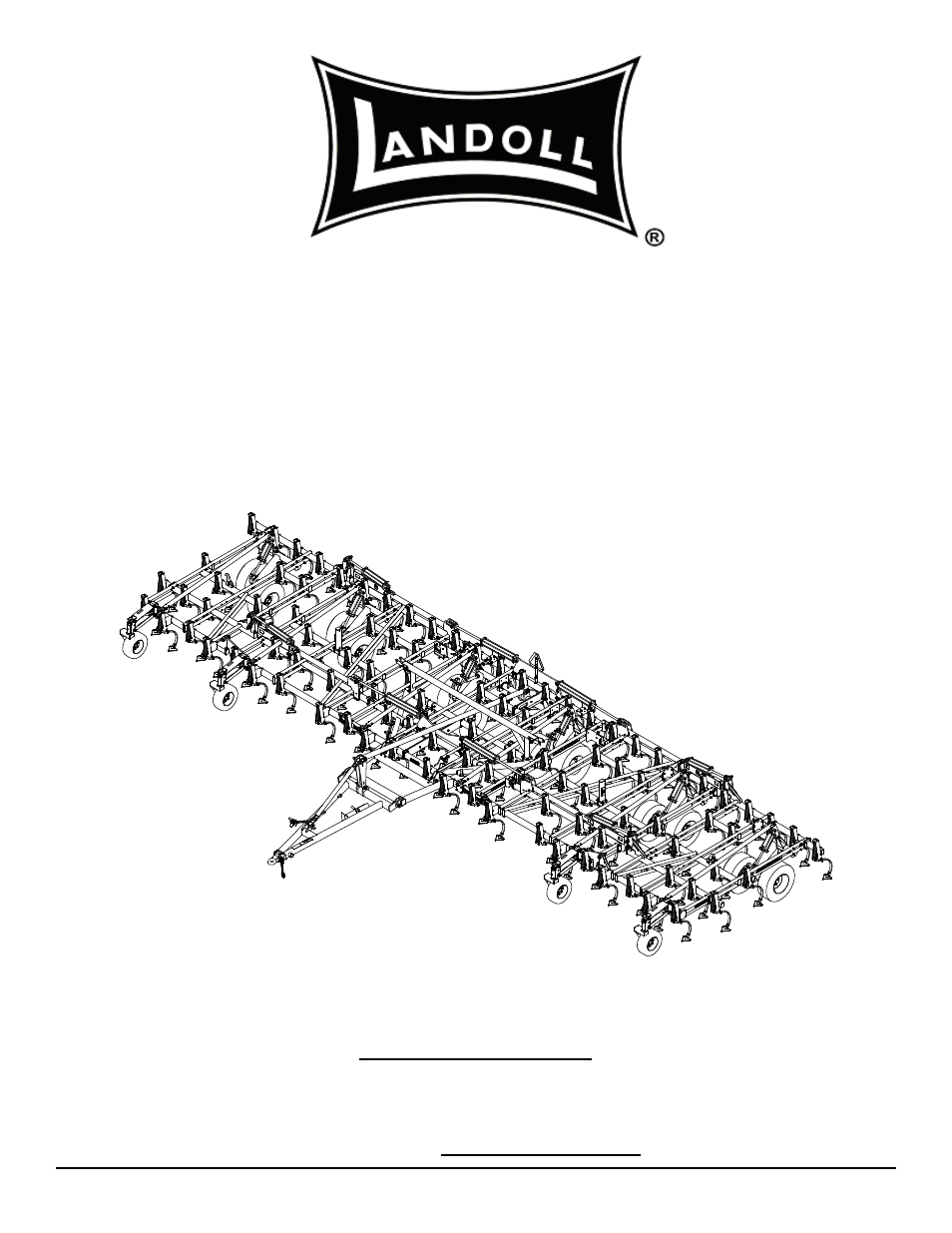

Landoll 9650 Field Cultivator User Manual

Model 9650 field cultivator operator’s manual

Table of contents

Document Outline

- Introduction

- Standard Specifications

- Table 2-1: General Torque Specifications

- Table 2-2: Hydraulic Fitting Torque Specifications

- Figure 2-1: Light and SMV Bracket Placement (All Models)

- Figure 2-2: Front Gauge Wheel Placement

- Figure 2-3: Shank Placement (38’ and 42' Models) (Main Frame)

- Figure 2-4: Shank Placement (38’ and 42' Models) (Right Wings Shown)

- Figure 2-5: Shank Placement (46' and 50’ Models) (Main Frame)

- Figure 2-6: Shank Placement (46’ and 50' Models) (Right Wings Shown)

- Figure 2-7: 4 Row Coil Tine Harrow Placement (38' Model) (Left Half)

- Figure 2-8: 4 Row Coil Tine Harrow Placement (38’ Model) (Right Half)

- Figure 2-9: 4 Row Coil Tine Harrow Placement (42' Model) (Left Half)

- Figure 2-10: 4 Row Coil Tine Harrow Placement (42’ Model) (Right Half)

- Figure 2-11: 4 Row Coil Tine Harrow Placement (46' Model) (Left Half)

- Figure 2-12: 4 Row Coil Tine Harrow Placement (46’ Model) (Right Half)

- Figure 2-13: 4 Row Coil Tine Harrow Placement (50' Model) (Left Half)

- Figure 2-14: 4 Row Coil Tine Harrow Placement (50’ Model) (Right Half)

- Figure 2-15: 5 Row Spike Harrow Placement (38' Model) (Left Half)

- Figure 2-16: 5 Row Spike Harrow Placement (38’ Model) (Right Half)

- Figure 2-17: 5 Row Spike Harrow Placement (42' Model) (Left Half)

- Figure 2-18: 5 Row Spike Harrow Placement (42’ Model) (Right Half)

- Figure 2-19: 5 Row Spike Harrow Placement (46' Model) (Left Half)

- Figure 2-20: 5 Row Spike Harrow Placement (46’ Model) (Right Half)

- Figure 2-21: 5 Row Spike Harrow Placement (50' Model) (Left Half)

- Figure 2-22: 5 Row Spike Harrow Placement (50’ Model) (Right Half)

- Figure 2-23: 3 Row Spike and Reel Harrow Placement (38' Model) (Left Half)

- Figure 2-24: 3 Row Spike and Reel Harrow Placement (38’ Model) (Right Half)

- Figure 2-25: 3 Row Spike and Reel Harrow Placement (42' Model) (Left Half)

- Figure 2-26: 3 Row Spike and Reel Harrow Placement (42’ Model) (Right Half)

- Figure 2-27: 3 Row Spike and Reel Harrow Placement (46' Model) (Left Half)

- Figure 2-28: 3 Row Spike and Reel Harrow Placement (46’ Model) (Right Half)

- Figure 2-29: 3 Row Spike and Reel Harrow Placement (50' Model) (Left Half)

- Figure 2-30: 3 Row Spike and Reel Harrow Placement (50’ Model) (Right Half)

- Assembly Instructions

- Figure 3-1: Frame and Hitch Assembly

- Frame and Hitch Assembly

- Center Frame Tire Installation

- Leveling Linkage Assembly

- Inner Wing Frames

- Outer Wing Frames

- Wing Lift Tire Installation

- Front Gauge Wheel Installation

- Lighting and SMV Bracket Installation

- Figure 3-6: Lift and Fold Manifold Hydraulic Installation

- Figure 3-7: Hydraulic Lift Installation (9650-38 & 9650-42)

- Figure 3-8: Hydraulic Fold Installation (9650-38 & 9650-42)

- Figure 3-9: Hydraulic Lift Installation (9650-46 & 9650-50)

- Figure 3-10: Hydraulic Fold Installation (9650-46 & 9650-50)

- Figure 3-11: Lift, Fold, and Transport Lock Hydraulic Cylinder Installation

- Hydraulic Installation

- Shank Installation

- 4 Row Coil Tine Harrow Installation

- 5 Row Spike Harrow Installation

- 3 Row Spike and Reel Harrow Installation

- Rear Tow Hitch (Option)

- Operation and Maintenance

- Hydraulic Lift System

- Hydraulic Fold System

- Transporting

- Tractor Preparation

- Prior to Transport

- Leveling (Front-to-Rear)

- Leveling (Side to Side)

- Gauge Wheels

- Depth Stop Adjustment

- General Operation

- Spring Shank

- Sweeps

- Wheel Bearing Maintenance

- Lubrication

- 4 Row Coil Tine Harrow

- 5 Row Spike Harrows

- 3 Row Spike and Reel Harrow

- Storage

- Troubleshooting Guide