Landoll XL144/XLC144/XLD144/XLH144/XLO144 X-Fold Pulverizer User Manual

Page 17

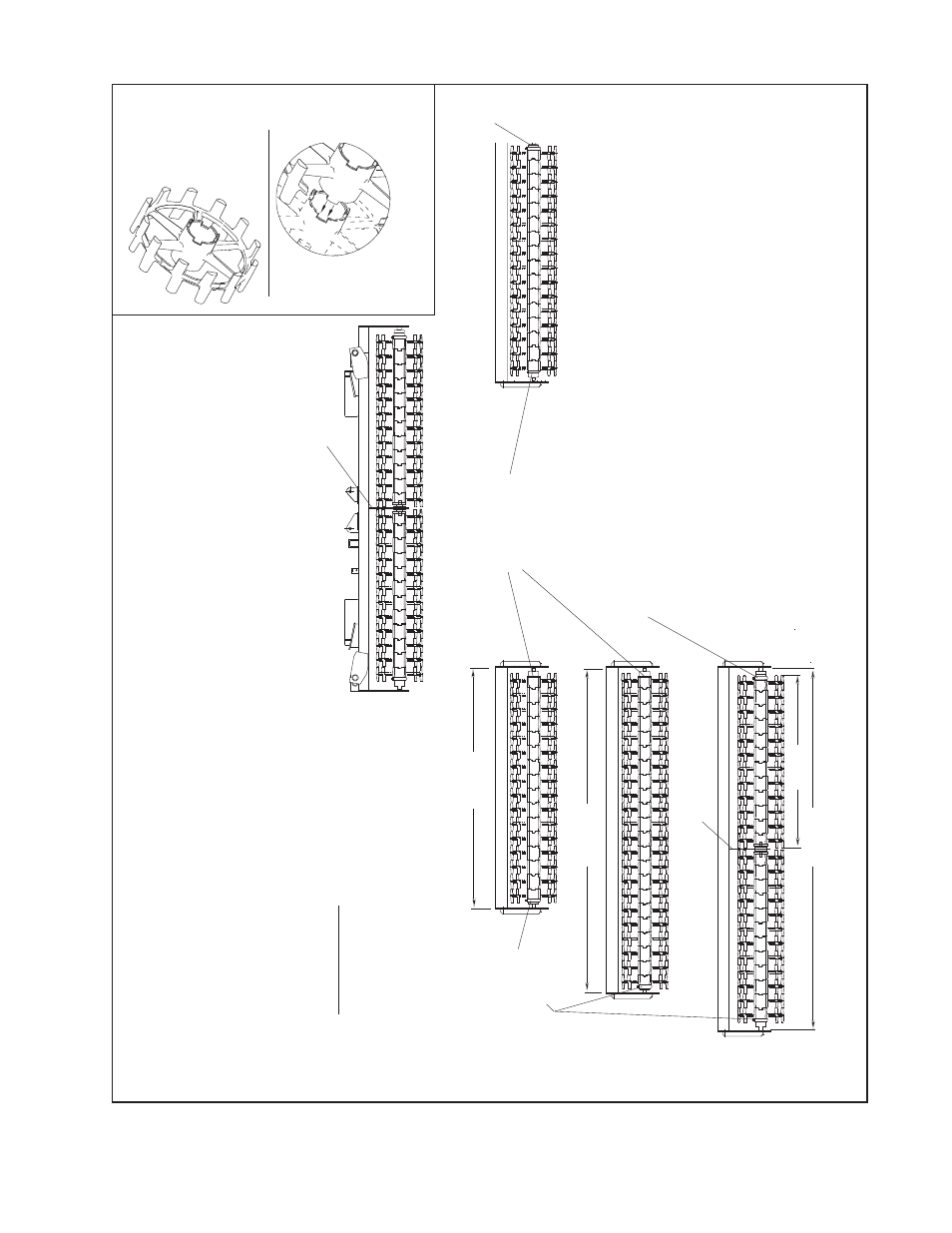

5J801

182rev501

Page 9B

OPTIMIZER

WHEEL

PLACEMENT

28’

- 36’

Wide

Models

with

20”

Optimizer

Wheels

-

4

1/2”

bore

(6K353

Wheel

&

6K354

End

Wheel)

“XLO”

Models

CENTER SECTION

(2x)10

Wheels,

(2x)2

End

Wheels)

WING ASSEMBL

Y

/ side:

8’=14

Wheels,

2

End

Wheels

9’=16

Wheels,

2

End

Wheels

10’=18

Wheels,

2

End

Wheels

11’=20

Wheels,

2

End

Wheels

12’=(2x)10

Wheels,

(2x)2

End

Wheels

Position Welded

Ring

on

Axle

to

inside

Male

&

female ends must mate and remain in close contact.

8’

Wing

Position Axle

Clamp

to

outside

Position Axle

Clamp

to

outside

11

’ W

in

g

The

above

diagram

shows

wheel

gang

positioning

and

assembly

for

the

center

and

wings

of

optimizer

model

pulverizers

using

optimizer

wheels.

When

assembling,

position

the

axle

clamps

toward

the

outside

end

of

the

wing

and

the

machine.

Also,

it is especially import

ant that fit of wheel

on the shaft remains tight. Wear and damage can result from wheels

that do not fit tightly against one another

. Make frequent checks to

insure that close fit remains intact. If wheels have jostled apart,

adjustment is made by loosening and moving the clamp until the

wheels are tightly in place. Then retighten clamp.

6K353

Optimizer Wheel

12’

Wing

Position

Axle

Clamps

to

ends

opposite

Center

Bearing

Center Bracket

Center Bracket

72

5/8”