INFICON RSH-600 Rotary Sensor User Manual

Page 24

3 - 2

IPN

1

5

3800

-G

RSH-600 Operating Manual

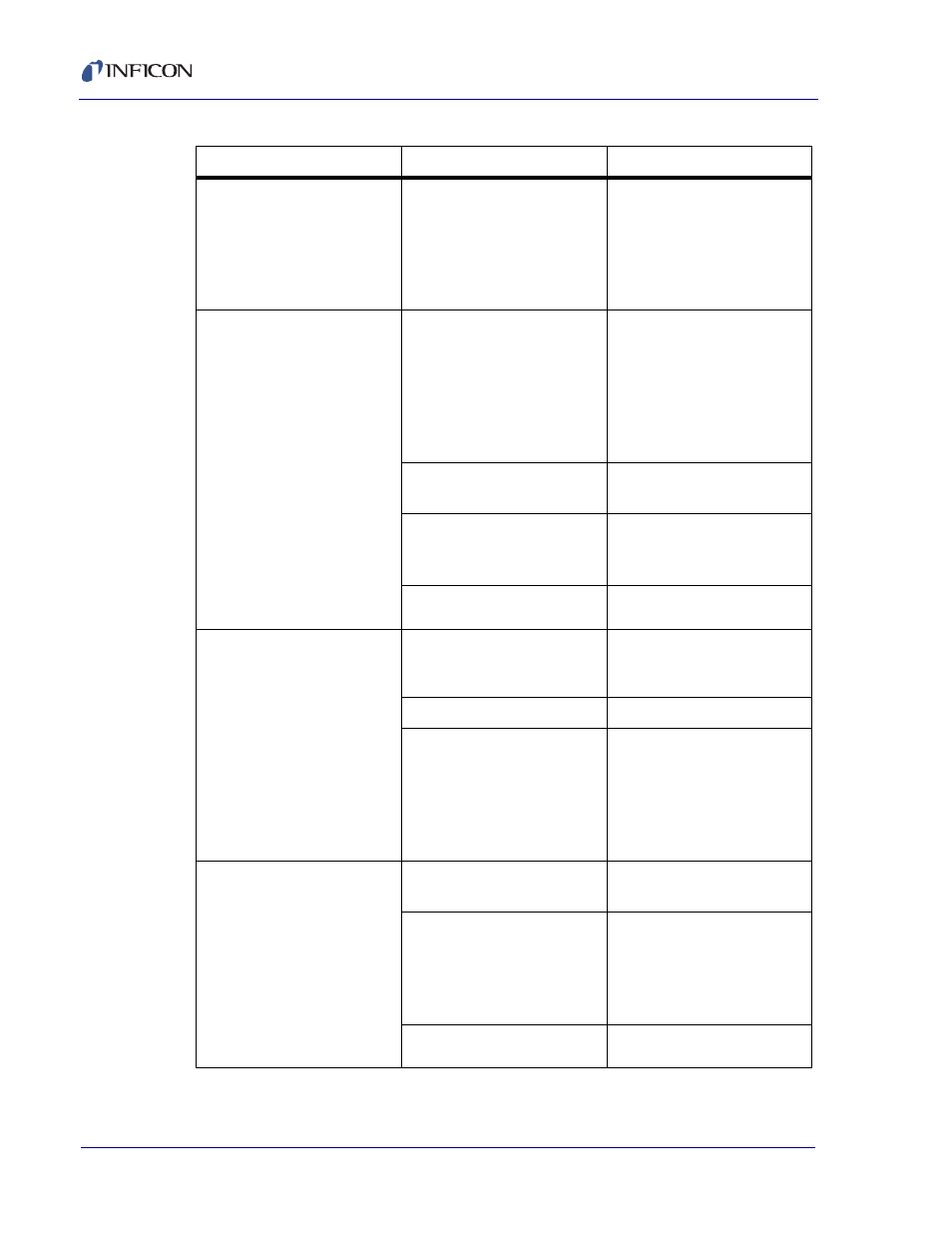

3. Crystal not centered in

aperture.

a. Improper alignment.

a. The RSH-600 should

realign automatically. Be

sure the correct air pressure

(55 psi) is used. Contact

INFICON if the issue

persists.

4. Large jumps of thickness

reading during deposition.

a. Mode hopping.

a. Mode hopping is a by

product of active oscillation

with a heavily damped

crystal. Temperature

stabilization is key in

diminishing this. Replace the

crystal.

b. Crystal near the end of its

life.

b. Replace crystal.

c. Scratches or foreign

particles on the crystal holder

seating surface.

c. Clean, polish the crystal

seating surface of the crystal

holder.

d. Insufficient crystal cooling. d.Check water flow and

temperature.

5. Crystal ceases to oscillate

during deposition before it

reaches its "normal" life.

a. Crystal is being hit by small

droplets of molten material

from the evaporation source.

a. Move the sensor further

away from the evaporant.

b.Damaged crystal.

b. Replace crystal.

c. Deposition material

built-up on the edge of the

crystal carousel aperture

plate and touching the

crystal, partially masking full

crystal area.

d. Clean the crystal carousel

aperture plate.

6. Crystal does not oscillate

or oscillates intermittently.

(both in vacuum and in air)

a. Defective or damaged

crystal.

a. Replace crystal.

b. Existence of electrical

short or poor electrical

contacts.

Check for electrical continuity

and short in sensor cable,

electrical connection

assembly, feedthroughs, and

crystals carousel.

d. Insufficient crystal cooling. d.Check water flow and

temperature.

Table 3-1 General Troubleshooting (continued)

SYMPTOM

CAUSE

REMEDY