Chapter 3 troubleshooting and maintenance, 1 troubleshooting, 2 troubleshooting the rsh-600 – INFICON RSH-600 Rotary Sensor User Manual

Page 23: Chapter 3

3 - 1

IPN

1

5

3800

-G

RSH-600 Operating Manual

Chapter 3

Troubleshooting and Maintenance

3.1 Troubleshooting

If the RSH-600 fails to function, or appears to have diminished performance, the

following Symptom/Cause/Remedy charts may be helpful.

WARNING

There are no user serviceable components within the

RSH-600 sensor.

Refer all maintenance to qualified INFICON personnel.

A useful tool for diagnosing sensor head problems is the DMM (Digital Multi-Meter).

Disconnect the short oscillator cable from the feedthrough and measure the

resistance from the center pin to ground. If the reading is less than 10 megohms

the source of the leakage should be found and corrected.

3.2 Troubleshooting the RSH-600

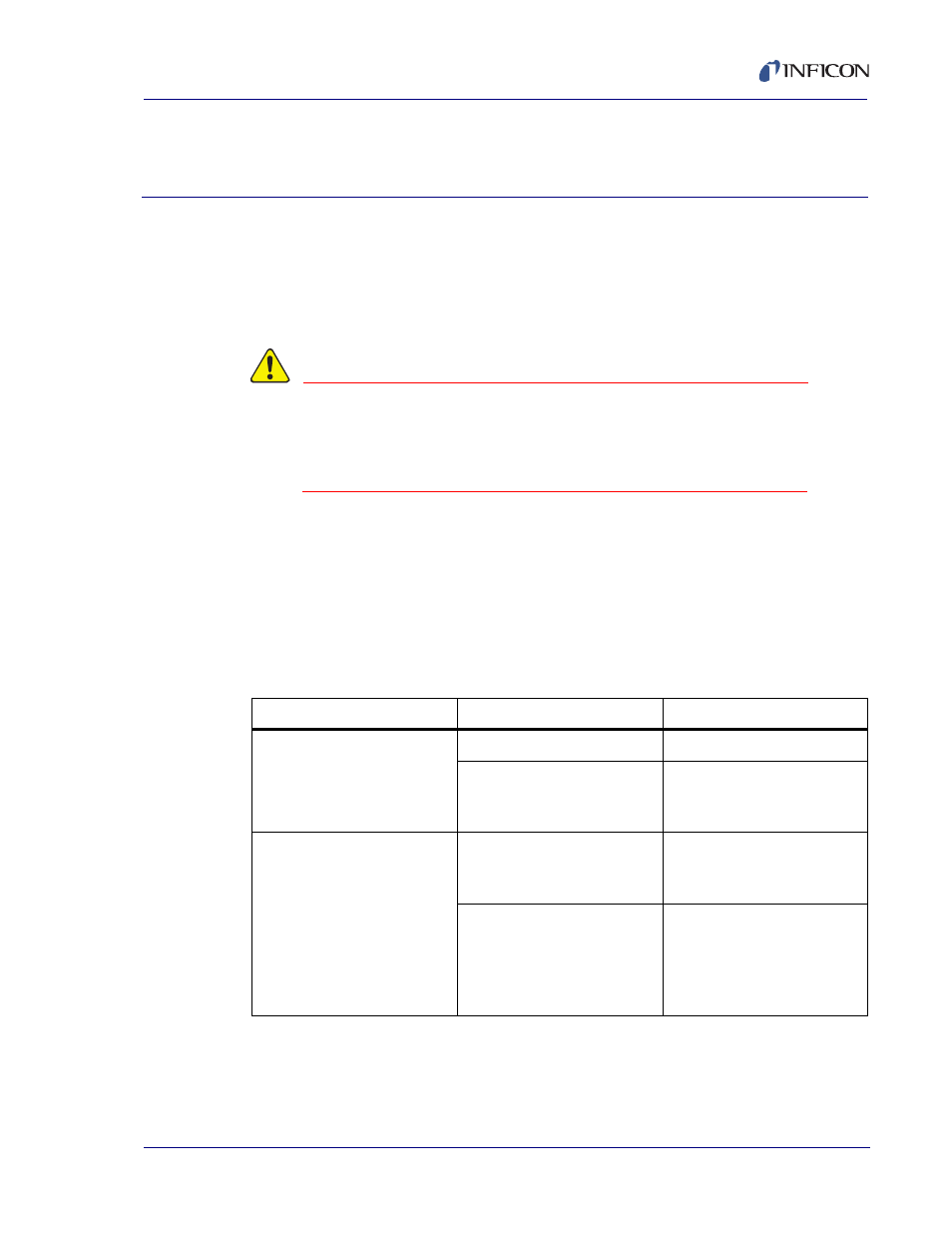

Table 3-1 General Troubleshooting

SYMPTOM

CAUSE

REMEDY

1. Crystal fail signal on front

panel of unit will not

disappear.

a. Damaged crystal.

a. Replace crystal.

b. Loss of electrical signal.

b. Check for electrical

continuity at the BNC

connector.

2. Unit will not advance when

crystal switch key is pressed.

Xtal switch error message

displayed.

a. Loss of pneumatic supply

or pressure is insufficient for

proper operation.

a. Establish air supply and

regulate to 55 psi.

b. Operation has been

impaired as a result of

peeling of the material

accumulated on the face of

the aperture plate.

b. Remove accumulated

material.