Sensitivity fault analysis, E 130, Figure e-4: sensitivity fault analysis – INFICON Sensistor ISH2000 Hydrogen Leak Detector User Manual

Page 83

EN- 83

Sensistor ISH2000 Technical Reference Manual (TRM)

E 130

h. Acceptance level for new sensor is minimum 1.2 = 1.20E+00.

i. If the Signal is below 1.2: Wait at least 10 minutes (leave instrument on)

and then repeat the test. If the Signal (after a repeated test) is still below

1.2 the sensor is to be considered no good for delivery.

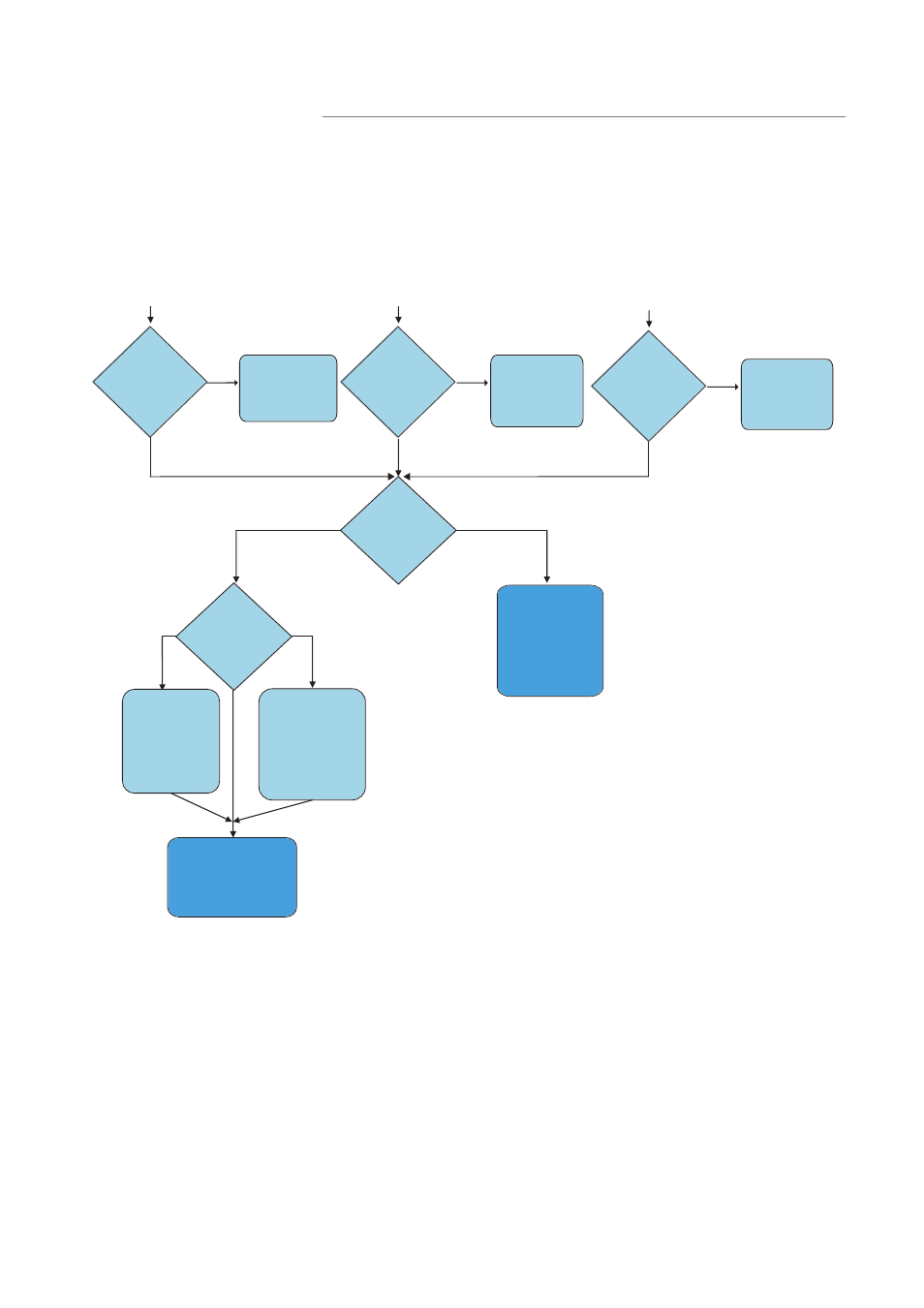

Sensitivity fault analysis

The following questions below are useful to detect a problem.

Figure E-4: Sensitivity fault analysis

Type of

problem?

Quick or

slow

signals?

Electrical fault.

Bad cable or

connector, or

earthing problem .

This is most

likely a handling

error by

customer.

Check for gas spillage

in the background.

(could be exhausts,

smoke, tracer gas or

gastric gases ) .

This is an application

problem. Not a

warranty issue.

Low sensitivity

False signals

>5 sec .

< 1 sec.

Detector

message:

“Check

Sensor,

Voltage Error”

Yes

No

1 -

5

sec.

No explanation

No explanation

* Service Mode Signal is read in Service Mode. See instructions for Sensitivity Test

Frequent unexplained

Service Mode Signals*

above 0.18 that can be

confirmed at the service

center are grounds for

warranty replacement.

The Reject level

should have been

designed to 10 ppm

H2 or more.

For Reject levels

it is normal to change

sensor 1-2 times per

year.

Detector

message:

“ Check

Probe and

Cable?”

Yes

Detector

message:

“ Check

Sensor, Temp”

Yes

Check that the sensor

is properly connected

to the probe. Refer to

D 200 General trouble

-shooting guide.

Check that the sensor

is properly connected

to the probe.Refer to

D 200 General trouble

-shooting guide

Check that the probe

cable is properly

connected to the probe

and the instrument.