INCRA Wonder Fence User Manual

Page 8

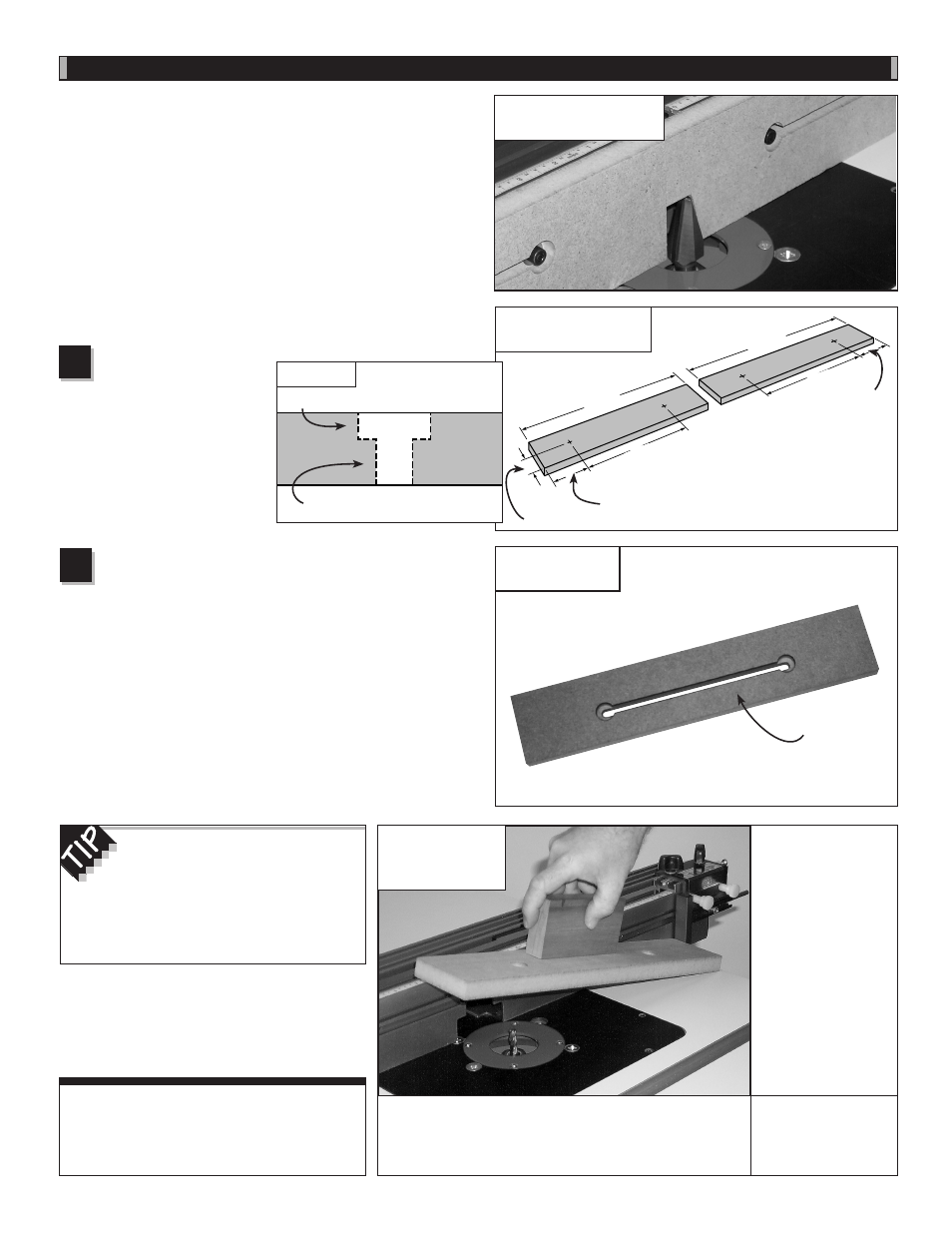

Adding a zero clearance subfence to your Wonder Fence

is a perfect solution to providing tearout control and

additional support for your workpiece when using large

diameter cutters . Typically a zero clearance subfence

is a long piece of wood with the profile of a particular

cutter bandsawn into the face . When attached to the

router table fence and moved into position, the router

bit nestles into the cutout . This close fit around the

cutter provides the tearout control and support for

your workpiece,

Fig. 17 . Here’s how to prepare a zero

clearance subfence for your Wonder Fence:

Making a zero clearance subfence blank

Begin with one piece of

3

⁄

4

" medium density fiberboard

3

1

⁄

16

" x 32" . Layout the

drill and counterbore

centers as shown in

Fig.-18,

then cut to the length as

shown . Drill and counterbore

at each center mark using the

dimensions in

Detail-18 .

8

Fig. 17

Zero clearance subfence

1

Fig. 18

Subfence dimensions

Detail 18

3

⁄

4

" dia. x

3

⁄

8

"deep counterbore

5

⁄

16

" dia. through hole

3

3

⁄

4

"

3

3

⁄

4

"

1

3

⁄

4

"

Fig. 19

Slot dimensions

Connect the through holes with a slot

In order to later access the fence offset adjustment

screws on your Wonder Fence, you’ll need to connect

the through holes on your zero clearance fence halves with a

slot . See

Fig 19 . Install a 5⁄16" straight bit in your router table

and set the depth of cut to 1⁄4" . Position your fence so that the

router bit will nestle into the through hole located at one end

of the subfence . Clamp a stop on your infeed fence against

the end of the zero clearance fence . Lift the zero clearance

fence off of the router and place the end of the zero clearance

fence against the stop . Now slowly lower the piece onto the

cutter . Slide the zero clearance fence forward until the router

bit is seen entering the rear hole . Slide the piece back to the

starting position and turn off the router .

2

Zero Clearance subfences

Fig. 20

Connect through

holes with slot

1

st

Pass:

5

⁄

16

"diameter cutter,

1

⁄

4

depth of cut

2

nd

Pass:

1

⁄

2

"depth of cut

3

rd

Pass:

3

⁄

4

"depth of cut

Double face tape

holds scrap of

wood to stock for

use as handle

To make this cutting operation

safer, use double-faced tape to

attach a scrap block of wood to the

zero clearance fence . The scrap can be

used as a handle to safely raise and

lower the stock .

Repeat this cut for the other zero clearance

fence . Next, increase the depth of cut by

1

⁄

4

"

and repeat the cutting process for both pieces .

Finally raise the bit to cut completely through

the stock and repeat the cuts .

First: Turn on

router and lower

stock onto cutter

Second: Slide

stock forward.

Stop cut when

router bit is seen

entering rear hole.

Third: Slide stock

back to starting

position and turn

off router.

CauTIOn: The cutter will be cutting

through the top of the stock. Keep your

fingers clear of the line of cut.

(See TIP above and Fig. 20.)

15

1

⁄

2

"

15

1

⁄

2

"

8"

8"

5

⁄

16

" wide slot

connecting both

5

⁄

16

"

through holes