Warranty – INCRA Miter 1000SE User Manual

Page 7

INCRA MITER1000SE OWNER’S MANUAL

©2008 by Taylor Design Group, Inc. All rights reserved. Rev.07.08.08

Page 7

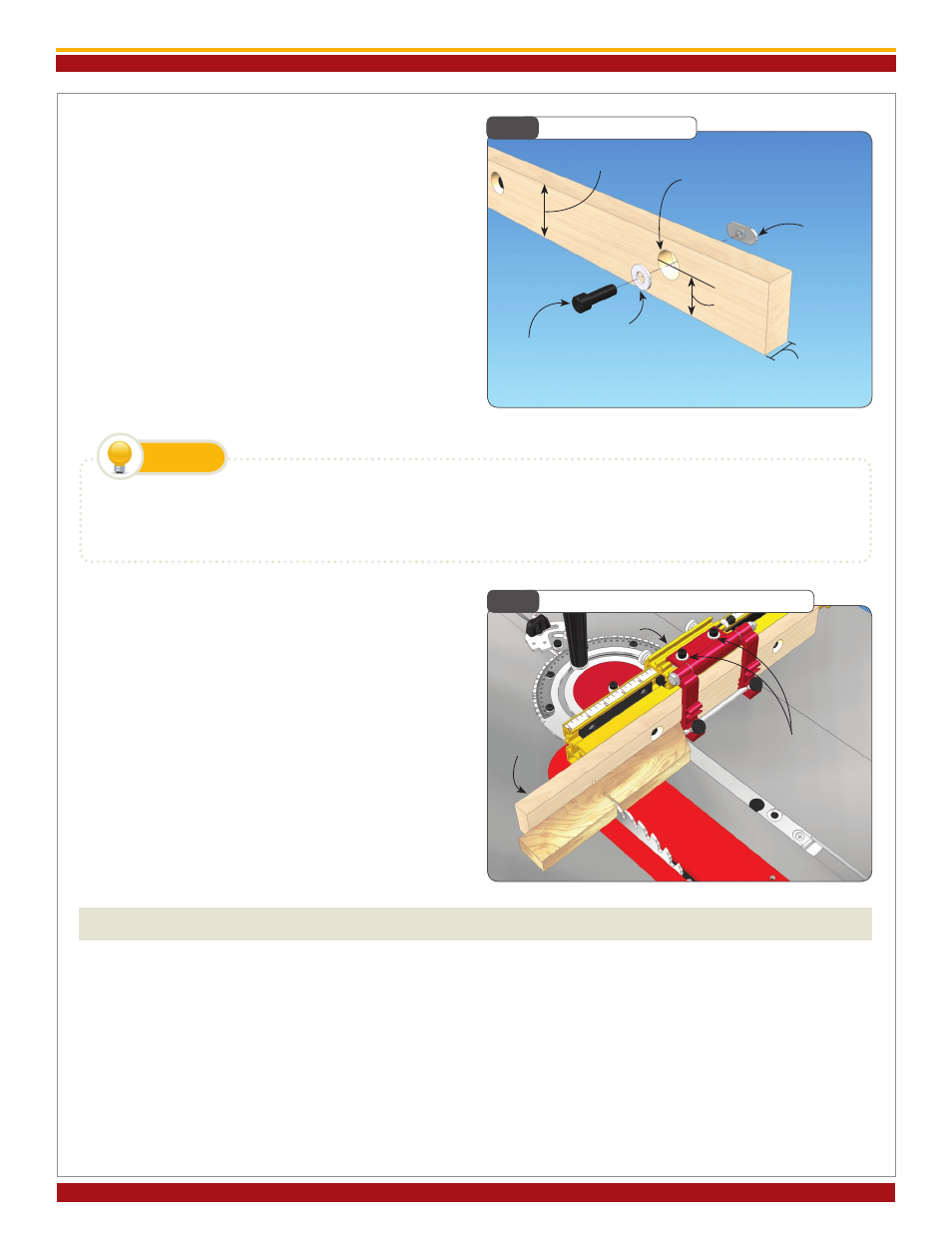

Making a Zero Clearance Wooden Sub

Fence

A sub fence can be used to provide tear out control

as well as support for your workpiece up to and be-

yond the blade. A good material to use for making

your zero clearance sub fence is

3/4

” medium density

fiberboard (MDF). Use the drill and counter bore di-

mensions shown in

Fig. 18. Attach using the supplied

fasteners. Adjust the length of the fence to accom-

modate your application. Note: In applications where

the incremental stopping capability of the Flip Shop

Stop is required, the wooden sub fence can be no

taller than 2-

1/2

”.

Expanded Flip Stop Clamping Mode

The two-part body design of the INCRA Flip Shop

Stop allows for use with up to a

3/4

” thick wooden sub

fence. To expand the INCRA Flip Shop Stop, loosen

the (2) socket head screws located on the top of the

stop body, then slide the upper portion of the stop

off. Now slide the upper portion back on, capturing

the rectangular nuts in the second T-slot located on

the lower portion (gold component) of the stop body,

Fig.19.

To avoid the saw blade pulling your workpiece into the cut, add a strip of adhesive backed sandpaper to the front

face of the wooden sub fence.

TIP

WARRANTY

TAYLOR dESIgN gROUP, INC. WARRANTS ThIS PROdUCT FOR ONE YEAR FROM dATE OF PURChASE. WE

WILL REPAIR ANY dEFECTS dUE TO FAULTY MATERIAL OR WORkMANShIP, OR AT OUR OPTION, REPLACE

ThE PROdUCT FREE OF ChARgE. PLEASE RETURN ThE FAILINg COMPONENT ONLY, POSTAgE PREPAId,

ALONg WITh A dESCRIPTION OF ThE PROBLEM TO ThE AddRESS BELOW. ThIS WARRANTY dOES NOT

APPLY TO PARTS WhICh hAvE BEEN SUBJECTEd TO IMPROPER USE, ALTERATION, OR ABUSE.

LIFETIME WARRANTY ON POSITIONING RACKS

IF AN INCRA POSITIONINg RACk IN ThIS TOOL BECOMES dAMAgEd FOR ANY REASON, TAYLOR dESIgN

gROUP WILL REPLACE IT FREE OF ChARgE FOR AS LONg AS YOU OWN YOUR TOOL. RETURN ThE dAM-

AgEd RACk, POSTAgE PREPAId, PLEASE ALLOW 1 TO 2 WEEkS FOR dELIvERY.

Fig. 18

Making a Sub Fence

Fig. 19

Expanded Flip Stop Clamping Mode

2

1/2

” max (see note)

5/16

” through hole w/

3/4

” dia. x

3/8

” deep

counter bore

1/4

-20

rectangular nut

1/4

” flat washer

1/4

-20 x

3/4

”

socket head screw

1

1/16

”

3/4

”

Gold component

Loosen socket head

screws and slide red

assembly into 2

nd

T-slot

on gold component

Sub fence