Chemical resistance, Additional information, Surface preparation – HMC Electronics 102-1 Permabond 102 Cyanoacrylate Adhesive, General Purpose, Plastic Bonding User Manual

Page 2: Directions for use, Storage & handling, Contact permabond, Strength retention

The information given and the recommendations made herein are based on our research and are believed to be accurate but no guarantee of their accuracy is made. In every case

we urge and recommend that purchasers before using any product in full-scale production make their own tests to determine to their own satisfaction whether the product is of

acceptable quality and is suitable for their particular purpose under their own operating conditions. THE PRODUCTS DISCLOSED HEREIN ARE SOLD WITHOUT ANY WARRANTY

AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED.

No representative of ours has any authority to waive or change the foregoing provisions but, subject to such provisions, our engineers are available to assist purchasers in adapting our products

to their needs and to the circumstances prevailing in their business. Nothing contained herein shall be construed to imply the non-existence of any relevant patents or to constitute a permission,

inducement or recommendation to practice any invention covered by any patent, without authority from the owner of this patent. We also expect purchasers to use our products in

accordance with the guiding principles of the Chemical Manufacturers Association’s Responsible Care® program.

Global TDS Revision 1

Page

2/2

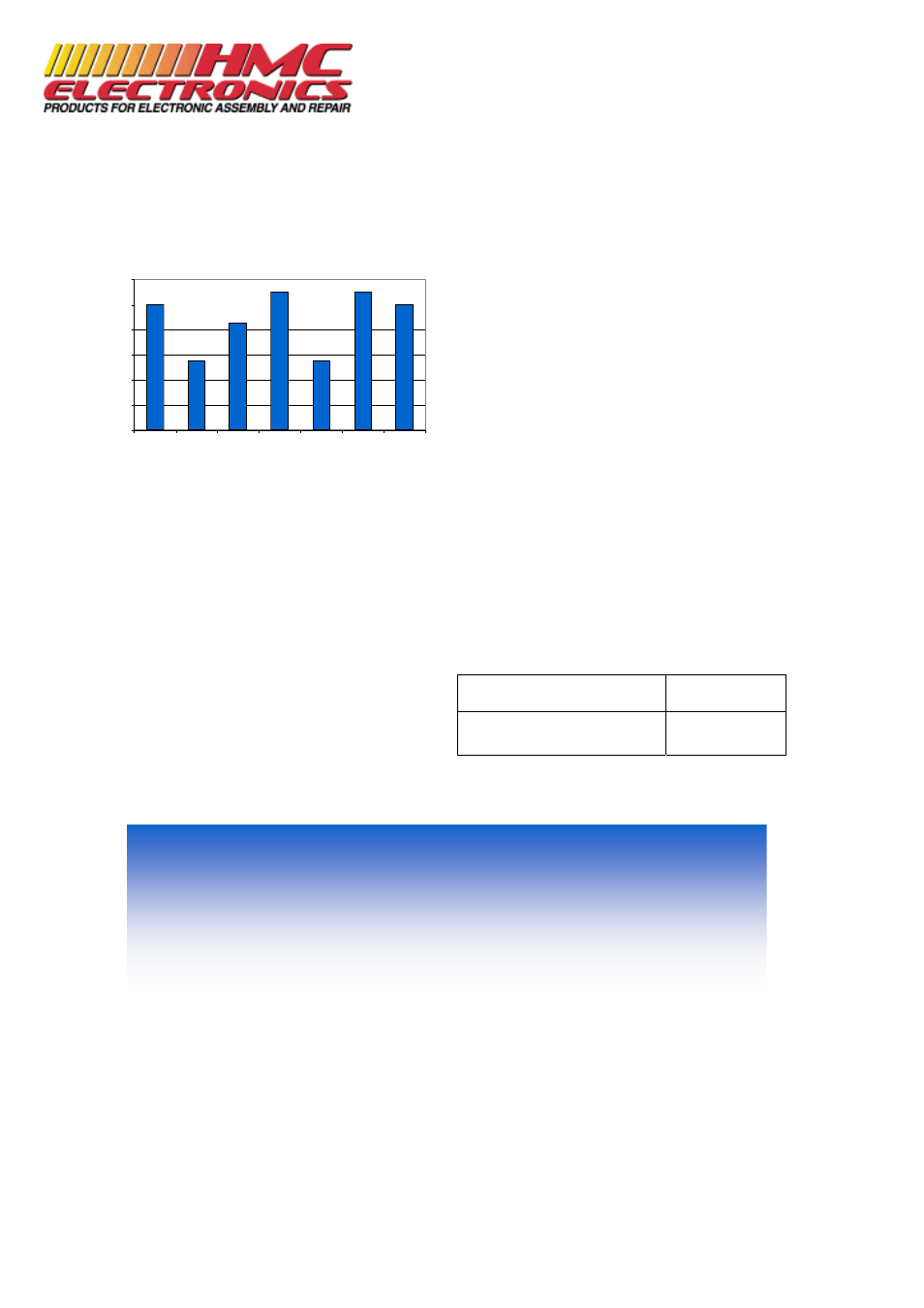

Chemical Resistance

0

20

40

60

80

100

120

A

ir

R

ef

er

en

ce

95

%

R

el

ati

ve

H

um

id

ity

4

0°

C

U

nl

ea

de

d

G

as

ol

in

e

M

oto

r O

il

@

40

°C

W

at

er

E

th

an

ol

Is

op

ro

pa

no

l

Specimens were immersed for 1000 hours at 22°C (unless otherwise

stated)

Additional Information

This product is not recommended for use in contact

with strong oxidizing materials and polar solvents

although will withstand a solvent wash without any

bond strength deterioration. Users are reminded

that all materials, whether innocuous or not, should

be handled in accordance with the principles of good

industrial hygiene. Full information can be obtained

from the Material Safety Data Sheet.

Surface Preparation

Surfaces should be clean, dry and grease‐free before

applying the adhesive. Use a suitable solvent (such as

acetone or isopropanol) for the degreasing of

surfaces. Some metals such as aluminium, copper

and its alloys will benefit from light abrasion with

emery cloth (or similar), to remove the oxide layer.

Directions for Use

1) Apply the adhesive sparingly to one surface

(usually 1 drop is sufficient).

2) Bring the components together quickly and

correctly aligned.

3) Apply sufficient pressure to ensure the

adhesive spreads into a thin film.

4) Do not disturb or re‐align until curing is

achieved, normally in a few seconds.

5) Any surplus adhesive can be removed with a

suitable solvent.

NB:

For difficult or porous surfaces using a

Permabond activator is recommended.

If bonding polypropylene, polyethylene, PTFE or

silicone, prime first with Permabond Polyolefin

Primer.

Storage & Handling

Storage Temperature

2 to 7°C

(35 to 45°F)

Shelf Life

Stored in original unopened containers

12 months

Allow adhesive to reach room temperature

before opening bottle to prevent condensation

inside the bottle which can reduce shelf life.

Contact Permabond:

Europe:

Tel. +44 (0)1962 711661

US:

Tel. +1 732‐868‐1372

UK Helpline: 0800 975 9800

Helpline: 800‐640‐7599

Deutschland: 0800 10 13 177

France: 0805 11 13 88

Asia:

Tel. +86 21 5773 4913

www.permabond.com

%

Strength

retention

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440