HMC Electronics 32430 Loctite 324 Speedbonder, High Impact Adhesive User Manual

Page 2

TDS LOCTITE

®

324™, February

-

2005

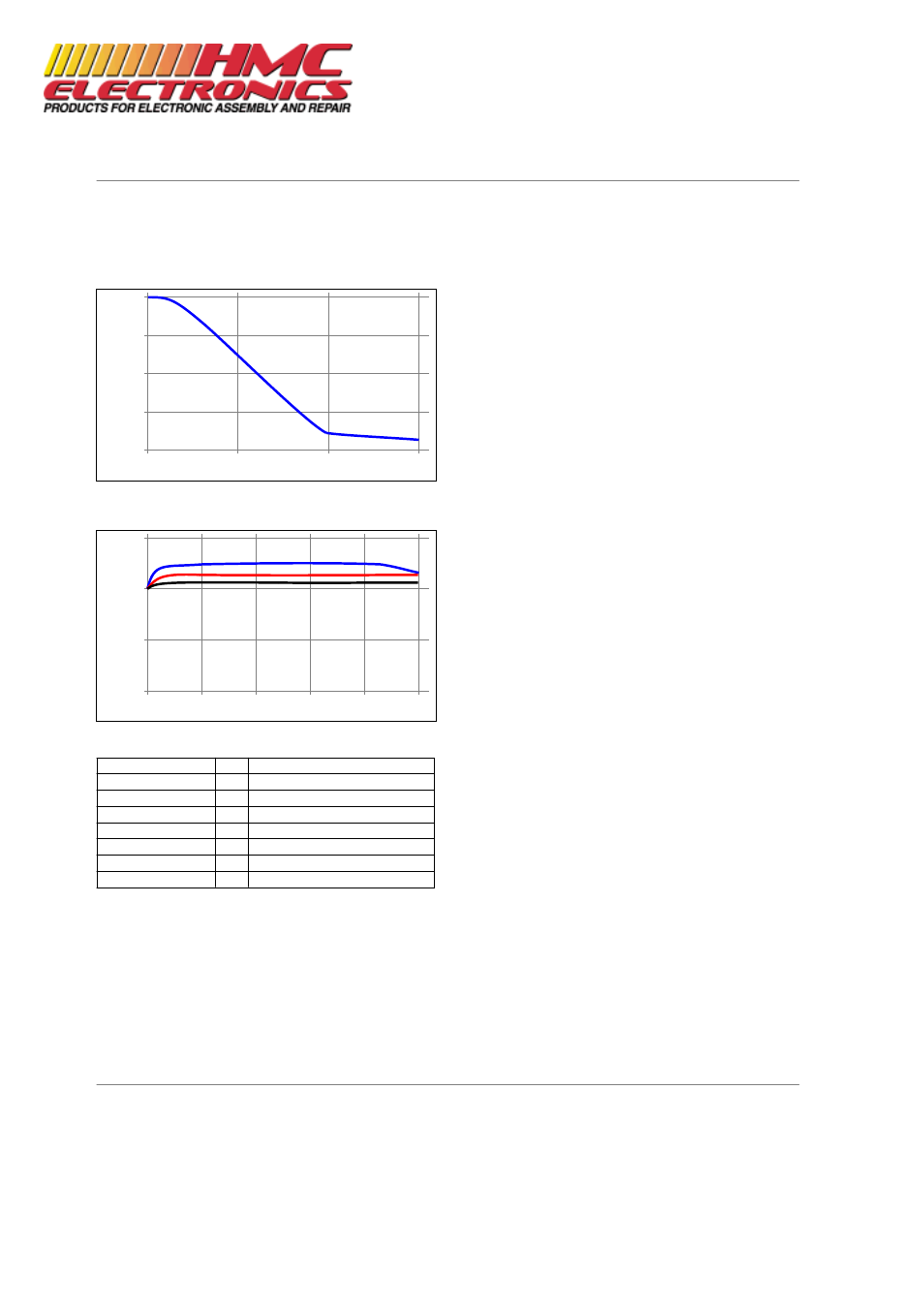

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C, Activator 7075™ on 1 side

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

100

75

50

25

0

0

50

100

150

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Hours

150

100

50

0

0

1000

2000

3000

4000

5000

100°C

120°C

150°C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

720 h

Gasoline

87

50

Motor oil

87

100

Auto trans. fluid

87

100

Phosphate ester

87

100

Water/glycol 50/50

150

50

Humidity, 100% RH

50

55

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Where aqueous washing systems are used to clean the

surfaces before bonding, it is important to check for

compatibility of the washing solution with the adhesive. In

some cases these aqueous washes can affect the cure and

performance of the adhesive.

This product is not normally recommended for use on plastics

(particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

compatibility of the product with such substrates.

Directions for use

1. For best performance bond surfaces should be clean and

free from grease.

2. To ensure a fast and reliable cure, Activator 7075™

should be applied to one of the bond surfaces and the

adhesive to the other surface. Parts should be assembled

within 15 minutes.

3. The recommended bondline gap is 0.1mm. Where bond

gaps are large (up to a maximum of 0.5 mm), or faster

cure speed is required, Activator 7075™ should be

applied to both surfaces. Parts should be assembled

immediately (within 1 minute).

4. Excess adhesive can be wiped away with organic solvent.

5. Bond should be held clamped until adhesive has fixtured.

6. Product should be allowed to develop full strength before

subjecting to any service loads (typically 24 to 72 hours

after assembly, depending on bond gap, materials and

ambient conditions).

Loctite Material Specification

LMS

LMS dated September

-

1, 1995. Test reports for each batch

are available for the indicated properties. LMS test reports

include selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or

greater than 28 °C can adversely affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Henkel Loctite Americas

+860.571.5100

Henkel Loctite Europe

+49.89.9268.0

Henkel Loctite Asia Pacific

+81.45.758.1810

For the most direct access to local sales and technical support visit: www.loctite.com

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440