HMC Electronics 40140 Loctite 401 Prism Instant Adhesive, Surface Insensitive, General Purpose User Manual

Page 2

TDS LOCTITE

®

401™, December

-

2009

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Cured for 10 seconds @ 22 °C

Tensile Strength, ISO 6922:

Buna-N

N/mm² ≥6.9

LMS

(psi) (≥1,000)

Cured for 72 hours @ 22 °C

Tensile Strength, ISO 6922:

Buna-N

N/mm² 8 to 15

(psi) (1,200 to 2,200)

Steel (grit blasted)

N/mm² 7 to 16

(psi) (1,000 to 2,300)

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

N/mm² 17 to 24

(psi) (2,500 to 3,500)

Aluminum (etched)

N/mm² 2 to 11

(psi) (290 to 1,600)

Zinc dichromate

N/mm² 0.5 to 2

(psi) (70 to 290)

ABS

N/mm² 7 to 9

(psi) (1,000 to 1,300)

PVC

N/mm² 7 to 16

(psi) (1,000 to 2,300)

Phenolic

N/mm² 1 to 5

(psi) (150 to 730)

Polycarbonate

N/mm² 7 to 11

(psi) (1,000 to 1,600)

Nitrile

N/mm² 1 to 2

(psi) (150 to 290)

Neoprene

N/mm² 1 to 2

(psi) (150 to 290)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

140

120

100

80

60

40

20

0

-40

-20

0

20

40

60

80

100

120

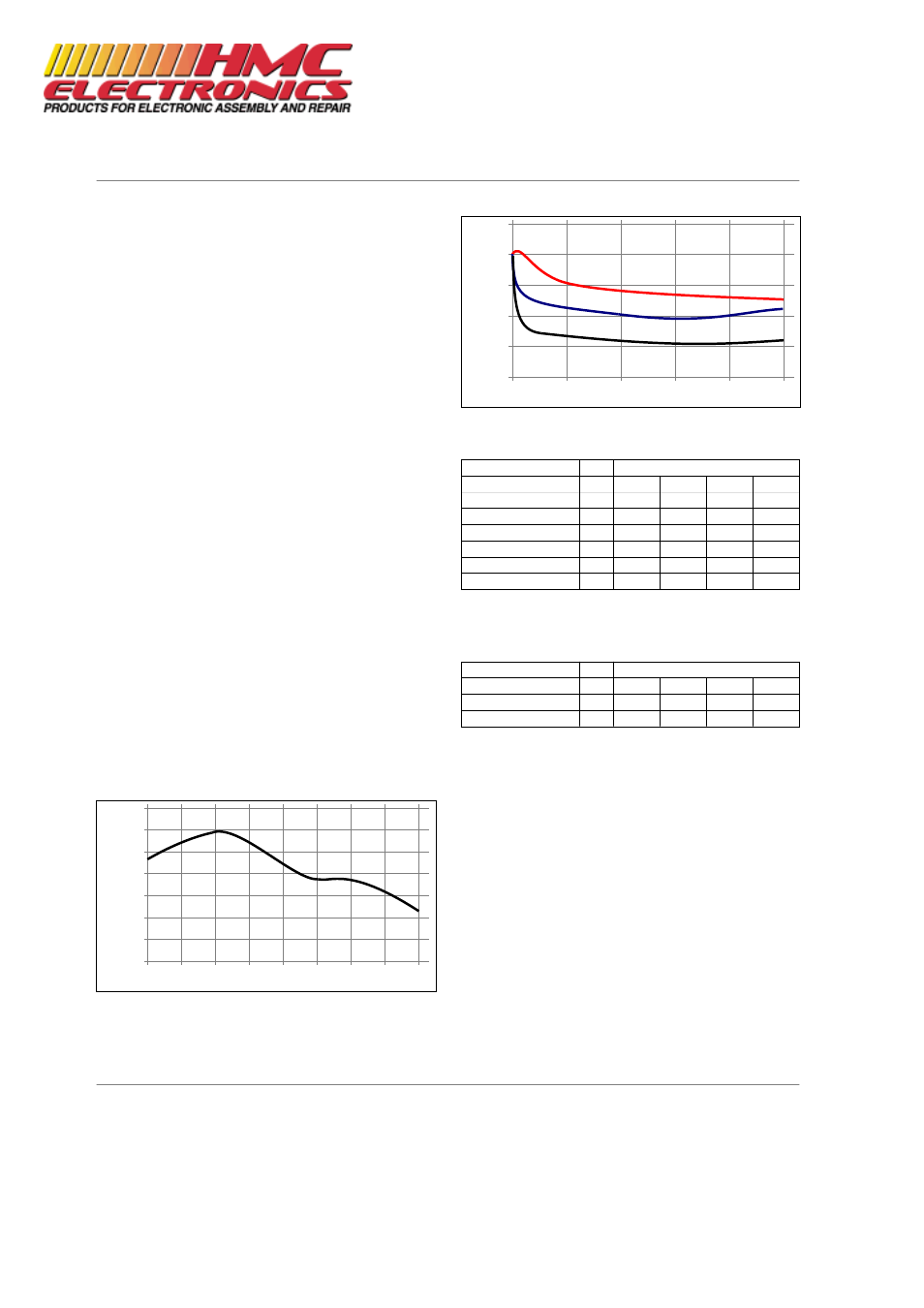

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

125

100

75

50

25

0

0

1000

2000

3000

4000

5000

60 °C

80 °C

100 °C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

100 h

500 h

1000 h

5000 h

Motor oil

40

120

110

110

85

Unleaded gasoline

22

85

80

80

75

Ethanol

22

100

105

110

120

Isopropanol

22

100

110

105

120

Water

22

80

70

55

65

98% RH

40

70

60

55

55

Lap Shear Strength, ISO 4587:

Polycarbonate

% of initial strength

Environment

°C

100 h

500 h

1000 h

5000 h

Air

22

120

125

115

130

98% RH

40

120

110

120

115

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use:

1. Bond areas should be clean and free from grease. Clean

all surfaces with a Loctite

®

cleaning solvent and allow to

dry.

2. Loctite

®

Primer may be applied to the bond area. Avoid

applying excess Primer. Allow the Primer to dry.

3. LOCTITE

®

Activator may be used if necessary. Apply the

LOCTITE

®

Activator to one bond surface (do not apply

activator to the primed surface where Primer is also

used). Allow the Activator to dry.

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440