HMC Electronics 41550 Loctite 415 SuperBonder, Instant Adhesive, Gap Filling Metal Bonder User Manual

Page 2

TDS LOCTITE

®

415™, January

-

2010

TYPICAL PROPERTIES OF CURED MATERIAL

After 24 hours @ 22 °C

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K

-1

100×10

-6

Coefficient of Thermal Conductivity, ISO 8302,

W/(m·K)

0.1

Electrical Properties:

Dielectric Constant / Dissipation Factor, IEC 60250:

0.1

-

kHz

2 to 3.3 / <0.02

1

-

kHz

2 to 3.5 / <0.02

10

-

kHz

2 to 3.5 / <0.02

Volume Resistivity, IEC 60093, Ω·cm

2×10

15

to 10×10

15

Surface Resistivity, IEC 60093, Ω

10×10

15

to 80×10

15

Dielectric Breakdown Strength,

IEC 60243-1, kV/mm

25

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Cured for 24 hours @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

N/mm² 20 to 30

(psi) (2,900 to 4,350)

Aluminum (grit blasted)

N/mm² 15 to 22

(psi) (2,175 to 3,190)

Zinc dichromate

N/mm² 4 to 12

(psi) (580 to 1,740)

ABS

N/mm² 6 to 20

(psi) (870 to 2,900)

PVC

N/mm² 6 to 20

(psi) (870 to 2,900)

Polycarbonate

N/mm² 5 to 20

(psi) (725 to 2,900)

Phenolic

N/mm² 5 to 15

(psi) (725 to 2,175)

Neoprene

N/mm² 5 to 15

(psi) (725 to 2,175)

Nitrile

N/mm² 5 to 15

(psi) (725 to 2,175)

Tensile Strength, ISO 6922:

Steel (grit blasted)

N/mm² 12 to 25

(psi) (1,740 to 3,625)

Buna-N

N/mm² 5 to 15

(psi) (725 to 2,175)

"T" Peel Strength, ISO 11339:

Steel (degreased)

N/mm <0.5

(lb/in) (<2.8)

Cured for 30 seconds @ 22 °C

Tensile Strength, ISO 6922:

Buna-N

N/mm² ≥6.0

LMS

(psi) (≥870)

TYPICAL ENVIRONMENTAL RESISTANCE

After 1 week @ 22 °C

Lap Shear Strength, ISO 4587:

Mild steel (grit blasted)

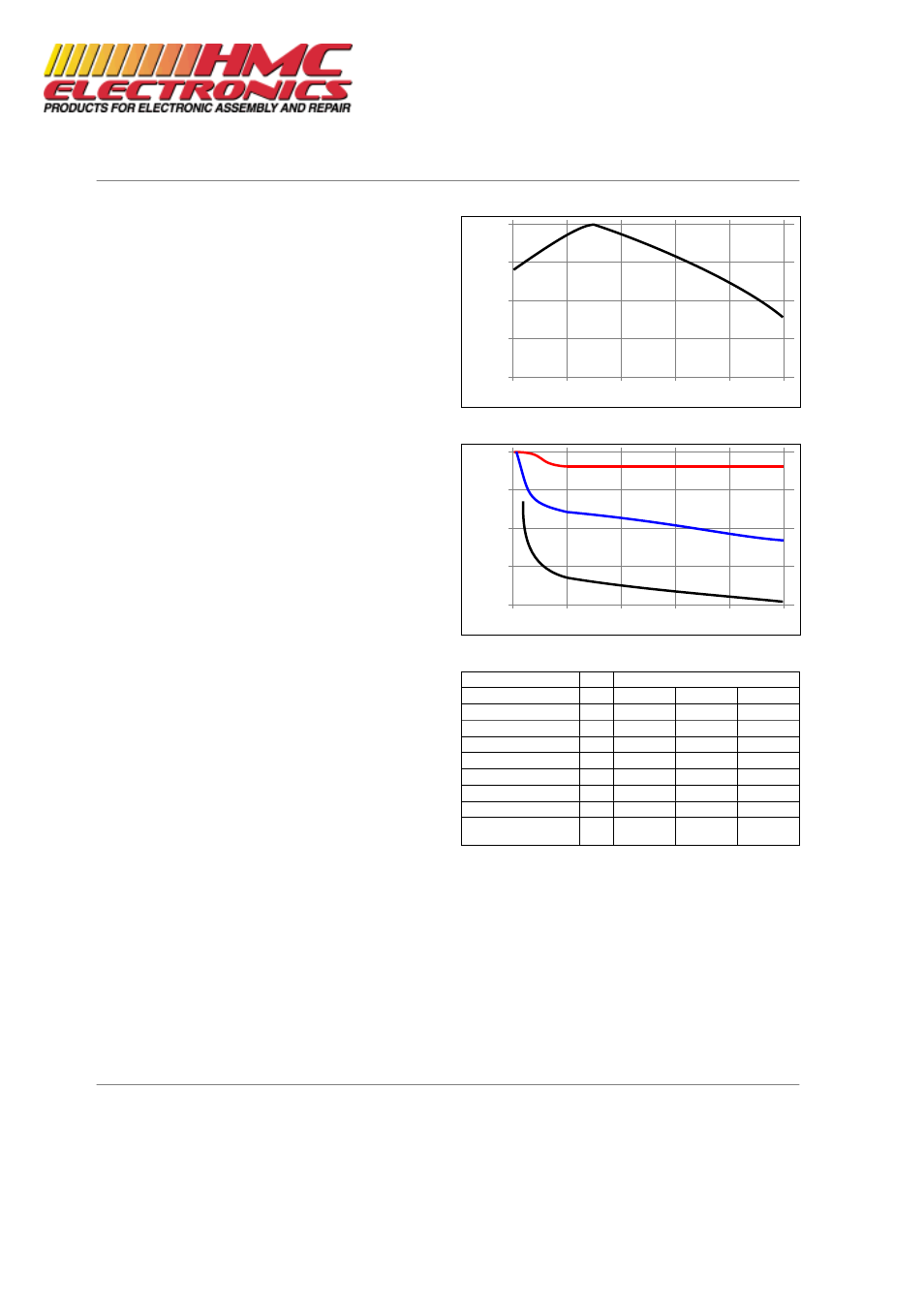

Hot Strength

Tested at temperature

% Initial Strength @ 22 °C

Temperature, °C

100

75

50

25

0

0

10

40

65

90

120

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

100

75

50

25

0

0

1000

2000

3000

4000

5000

60 °C

80 °C

100 °C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

100 h

500 h

1000 h

Motor oil (MIL-L-46152)

40

100

100

100

Gasoline

22

95

95

95

Isopropanol

22

95

95

95

Ethanol

22

100

100

100

Freon TA

22

95

95

95

1,1,1 Trichloroethane

22

95

95

95

Heat/humidity 95% RH

40

70

50

40

Heat/humidity 95% RH

on polycarbonate

40

95

95

95

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use:

1. For best performance bond surfaces should be clean and

free from grease.

2. This product performs best in thin bond gaps (0.05 mm).

3. Excess adhesive can be dissolved with Loctite cleanup

solvents, nitromethane or acetone.

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440