HMC Electronics 40840 Loctite 408 Prism Instant Adhesive, Low Odor, Low Bloom, Wicking Grade User Manual

Page 2

TDS LOCTITE

®

408™, June

-

2007

Phenolic

N/mm² 1 to 3

(psi) (150 to 440)

Polycarbonate

N/mm² 6 to 11

(psi) (870 to 1,600)

Nitrile

N/mm² 0.5 to 1.5

(psi) (70 to 220)

Neoprene

N/mm² 0.5 to 1.5

(psi) (70 to 220)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

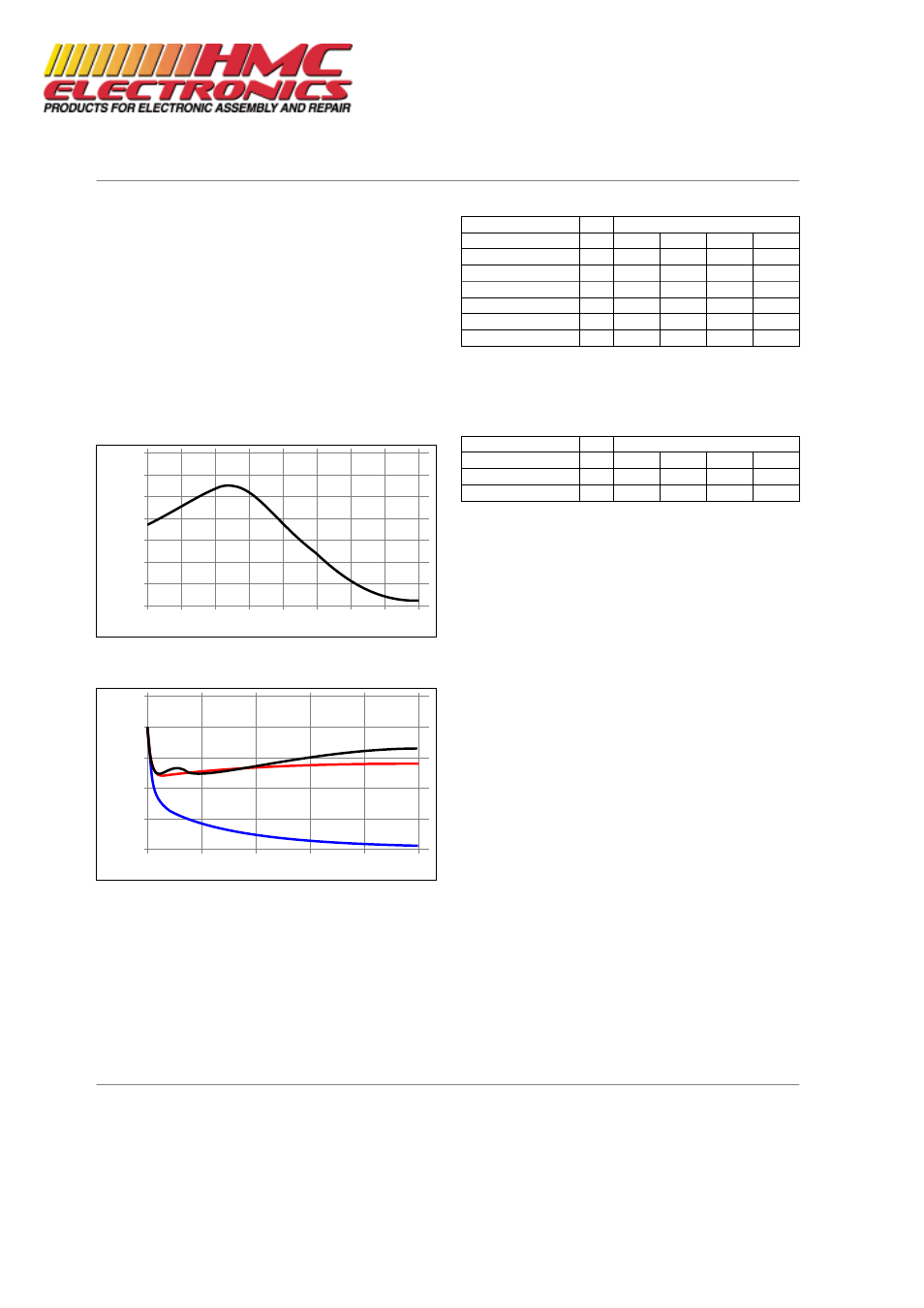

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

140

120

100

80

60

40

20

0

-40

-20

0

20

40

60

80

100

120

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

125

100

75

50

25

0

0

1000

2000

3000

4000

5000

100 °C

80 °C

60 °C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

100 h

500 h

1000 h

5000 h

Motor oil

40

85

75

60

55

Unleaded gasoline

22

90

80

75

65

Ethanol

22

100

90

110

110

Isopropanol

22

95

100

100

120

Water

22

65

30

30

5

98% RH

40

45

40

35

0

Lap Shear Strength, ISO 4587:

Polycarbonate

% of initial strength

Environment

°C

100 h

500 h

1000 h

5000 h

Air

22

75

60

65

75

98% RH

40

85

70

80

85

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use

1. Bond areas should be clean and free from grease. Clean

all surfaces with a Loctite

®

cleaning solvent and allow to

dry.

2. Loctite

®

Primer may be applied to the bond area. Avoid

applying excess Primer. Allow the Primer to dry.

3. LOCTITE

®

Activator may be used if necessary. Apply the

LOCTITE

®

Activator to one bond surface (do not apply

activator to the primed surface where Primer is also

used). Allow the Activator to dry.

4. Apply adhesive to one of the bond surfaces (do not apply

the adhesive to the activated surface). Do not use items

like tissue or a brush to spread the adhesive. Assemble

the parts within a few seconds. The parts should be

accurately located, as the short fixture time leaves little

opportunity for adjustment.

5. LOCTITE

®

Activator can be used to cure fillets of product

outside the bond area. Spray or drop the activator on the

excess product.

6. Bonds should be held fixed or clamped until adhesive has

fixtured.

7. Product should be allowed to develop full strength before

subjecting to any service loads (typically 24 to 72 hours

after assembly, depending on bond gap, materials and

ambient conditions).

Henkel Loctite Americas

+860.571.5100

Henkel Loctite Europe

+49.89.9268.0

Henkel Loctite Asia Pacific

+81.45.758.1810

For the most direct access to local sales and technical support visit: www.loctite.com

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440