Heidolph ROTAVAC Vario pumping unit User Manual

Page 48

page 48 of 61

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999248 / 28/04/2011

Attention: All error messages including a flashing warning triangle have to be confirmed (de-

leted) by pressing key START/STOP.

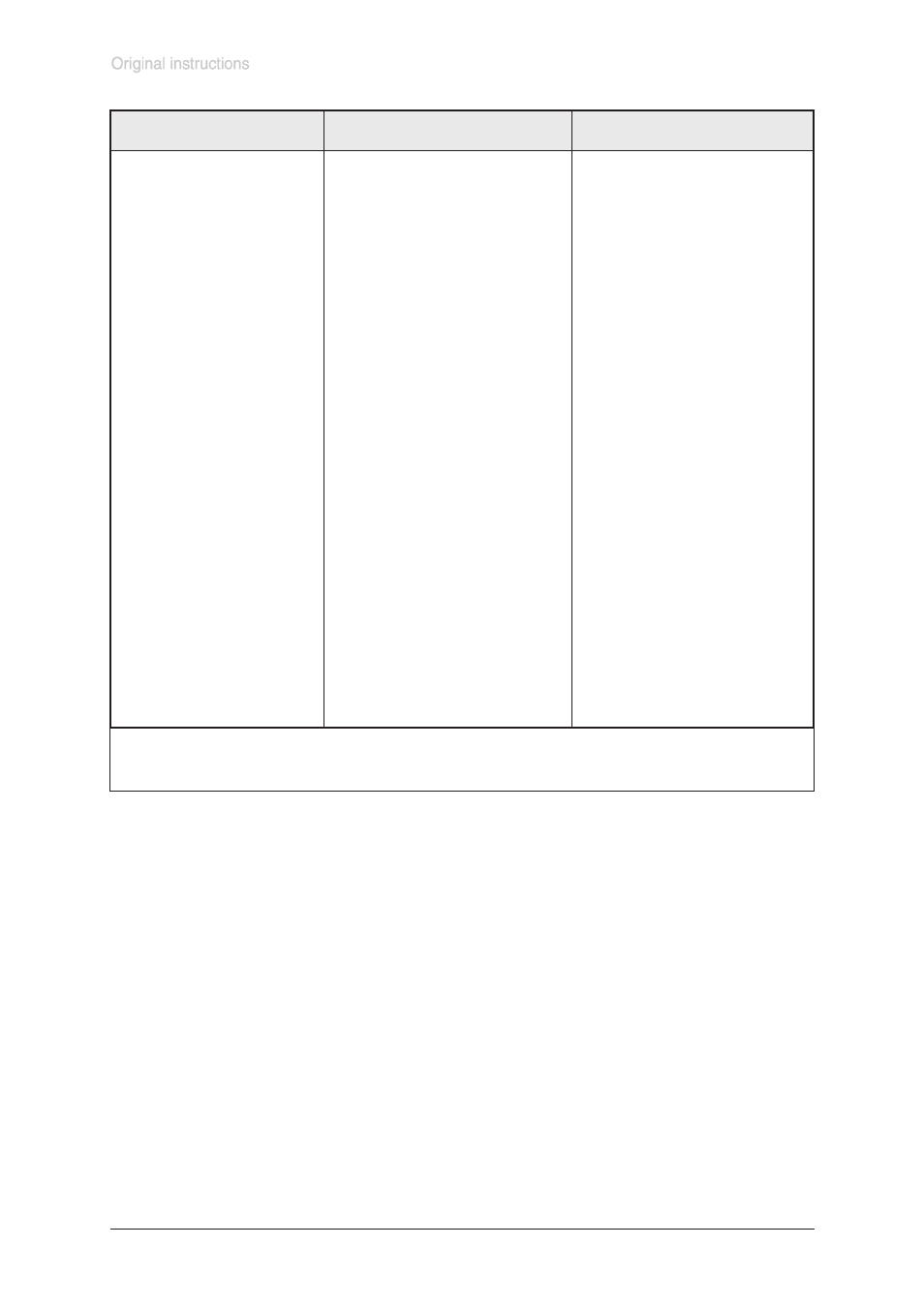

Fault

Possible cause

Remedy

❑ Pump does not achieve

ultimate vacuum or nor-

mal pumping speed.

➨ Wrong settings at controller? ✔ Select function ”Pump down”

with speed set to ”HI” and

check again.

➨ Centring ring at a small flange

connection not correctly posi-

tioned or leak in the pipeline

or vacuum system?

✔ Check pump directly - con-

nect controller directly at

pump inlet - then check con-

nection, pipeline and vacuum

system if necessary.

➨ Long, narrow vacuum line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Pump has been exposed to

condensate?

✔ Allow pump to run for some

minutes with atmospheric

pressure at the inlet.

➨ Deposits have been formed

inside the pump?

✔ Clean and inspect the pump

heads.

➨ Diaphragms or valves defec-

tive?

✔ Replace diaphragms and/or

valves.

➨ Outgassing substances or

vapour generated in the proc-

ess?

✔ Check process parameters.

➨ Pump too hot?

✔ Allow pump to cool down.

Determine and eliminate the

cause of overheating.

➨ Pressure for automatic

switching off reached?

✔ Adapt pressure for automatic

switching off, if necessary.