Operating instructions safety system ces-az-als – EUCHNER CES-AZ-ALS-xxx (Unicode) User Manual

Page 15

Operating Instructions Safety System CES-AZ-ALS-...

15

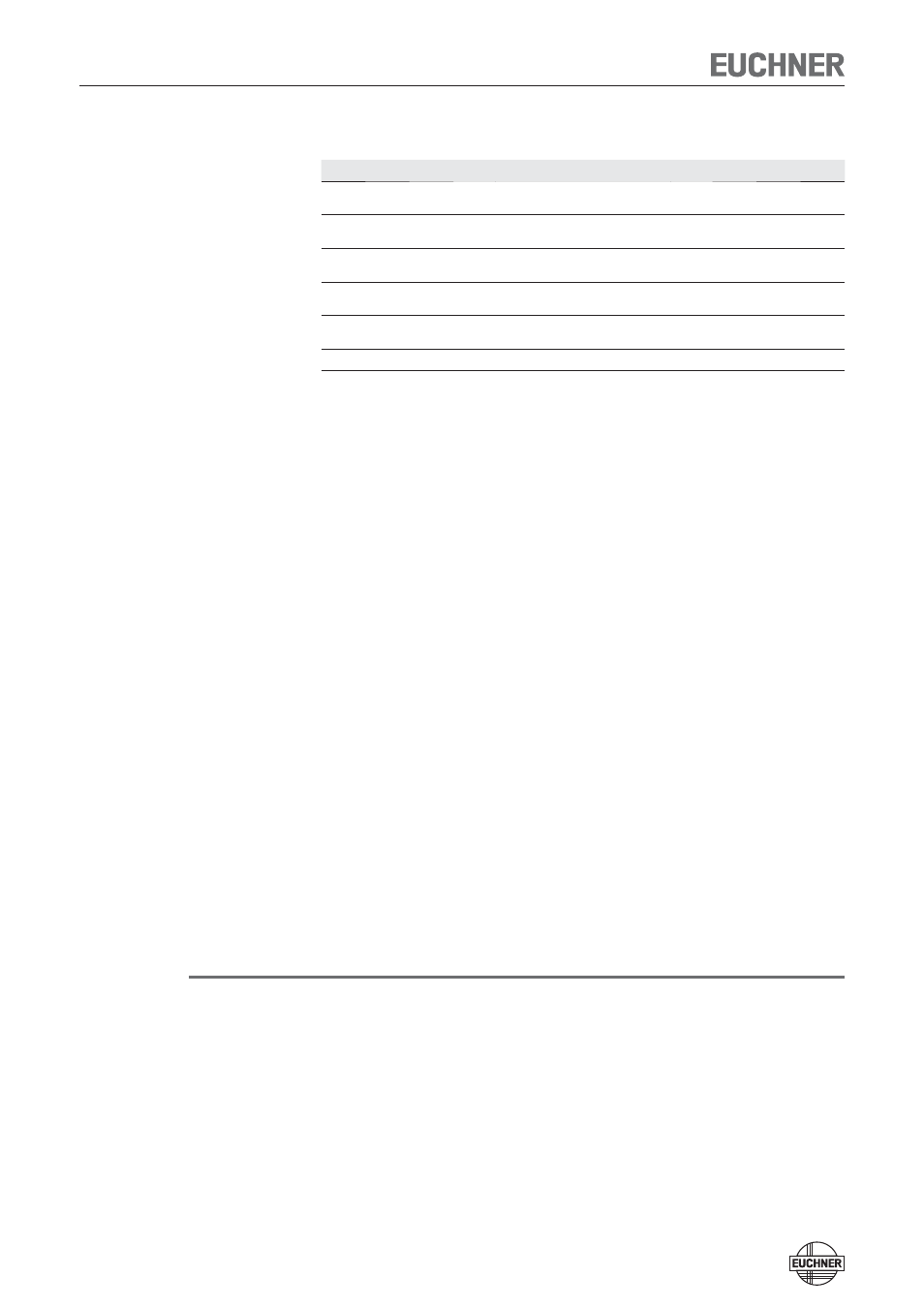

2. Set required configuration on DIP switches (activate inputs for read heads)

Switch designation

Switch position left (OFF)

Switch position right (ON)

1

No read head connected to

terminals H11, H12, SH1

Read head connected to

terminals H11, H12, SH1

2

No read head connected to

terminals H21, H22, SH2

Read head connected to

terminals H21, H22, SH2

3

No read head connected to

terminals H31, H32, SH3

Read head connected to

terminals H31, H32, SH3

4

No read head connected to

terminals H41, H42, SH4

Read head connected to terminals

H41, H42, SH4

5

Automatic start

(No start button connected)

Manual start

(Start button connected)

6

No feedback loop connected

Feedback loop connected

3. Set required configuration on machine

Ì

Close all doors to be monitored (the actuators must be in the operating

distance of the related read head)

Ì

For operating mode Manual start: keep start button closed

Ì

For operating mode With feedback loop: keep feedback loop closed

4. Start teach-in operation

Ì

Switch on operating voltage

Ì

Wait for self-test (STATE LED flashes for approx. 10 seconds at 15 Hz)

Ì

Teach-in operation starts (STATE LED flashes at approx. 1 Hz)

Ì

Wait for acknowledgement of the teach-in operation (STATE LED goes out

after approx. 10 seconds)

5. End teach-in operation

Ì

Remove jumper between J1 and J2 (on CES-AZ-ALS-01B between J and 0V)

Ì

For operating mode Manual start: start button must be connected

Ì

For operating mode With feedback loop: feedback loop must be con-

nected

Ì

Press reset button or interrupt operating voltage for at least 10 seconds

Ì

Wait for self-test (STATE LED flashes for approx. 10 seconds at 15 Hz)

6. Check all safety guards for effectiveness

Changing the configuration / new actuator

The evaluation unit can be re-configured as often as required. For this purpose you

must proceed as per the first teach-in operation according to the Setup procedure

section.

Faulty actuators can be replaced. Then a complete teach-in operation must be

performed as per the section Setup . The number of teach-in operations is unlimited.

Tip!

After acknowledging the teach-in operation you can use the monitoring outputs O1

... O4 for the diagnostics. All actuators that are in the operating distance of a read

head at this time are signaled on the related monitoring output. In the case of an

fault you can quickly see which actuators have not been detected, e. g. because it

has been forgotten to close a safety door prior to teach-in.

This function is only available during setup.