Checking threads and bar end engagement – ERICO Standard Bar Threader User Manual

Page 17

www.erico.com

17

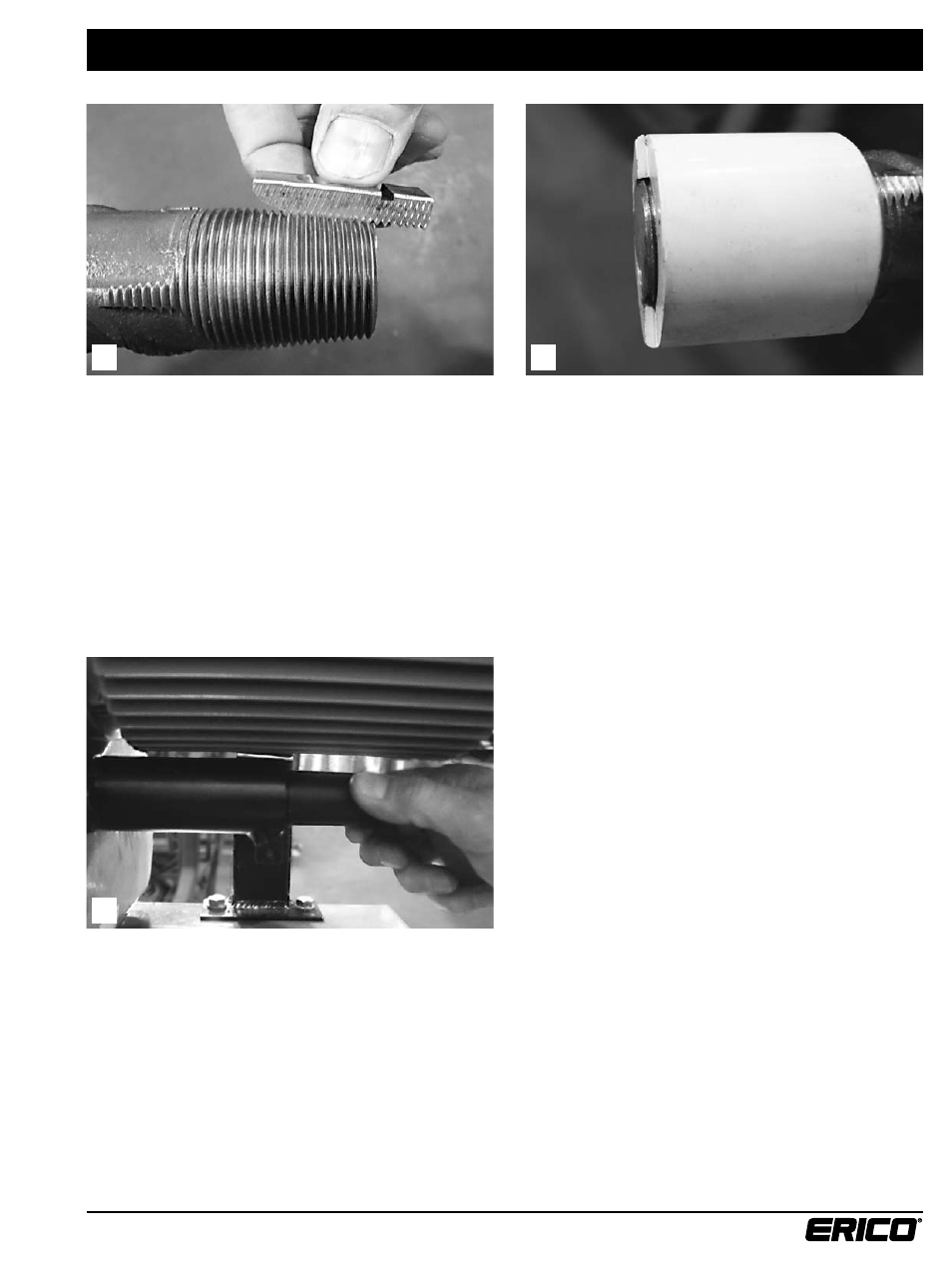

The thread profile should be checked with a brand new chaser.

To check the length of the thread, slide the bar end gauge

over the bar and look to see if the end of the bar falls within

the step range of the gauge.

Checking Threads and Bar End Engagement

NOTE: More detailed thread inspection procedures

can be found in the LENTON

®

product document:

Bar Fabrication Procedures (PDF118).

If the length of the thread is off in step 2, the adjustment

screw below the motor is used to make up the difference.

Turning it in (counter-clockwise), makes the thread longer;

turning it out (clockwise), makes the thread shorter.

If the length of the thread is off, the proper adjustment can

easily be made by measuring the amount of protrusion from

or recession into the gauge.

Example: If the bar is protruding beyond the gauge by

1/8 inch you would turn the adjustment screw in (clockwise)

so that the machine body would move forward 1/8 inch.

If the bar was 1/8 inch too short you would turn the screw

out (counter-clockwise) moving the body of the machine

back 1/8 inch.

A scrap piece of bar should be used to set the bar end

gauge prior to making a production run.

2

1

3