ERICO Stamped Bonding Lugs User Manual

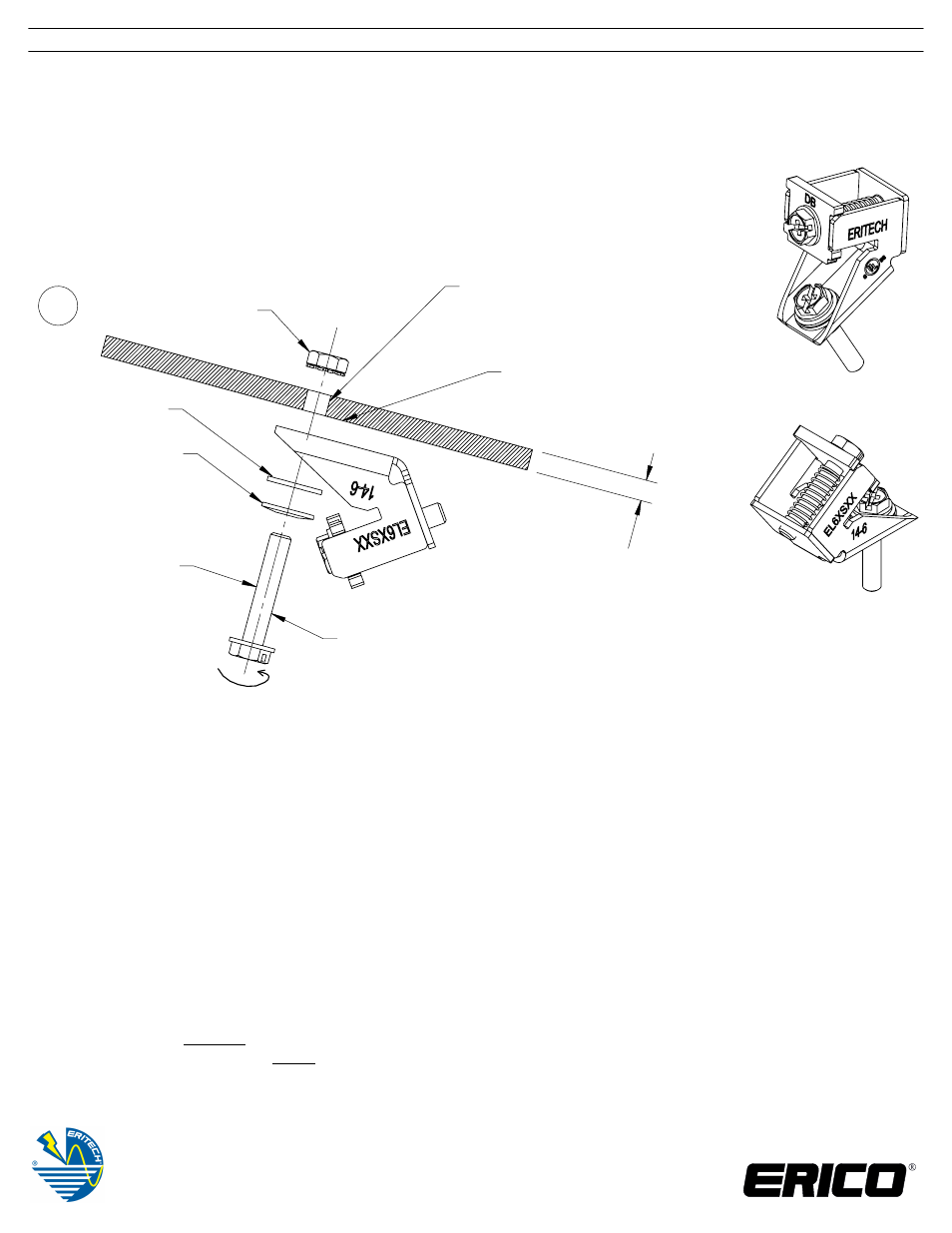

Stamped bonding lugs

Steel: 3/16" - 1/2" [4.8 - 12.5mm]

Aluminum: 1/16" - 1/2" [1.6 - 12.5mm]

Copper: 1/16" - 1/2" [1.6 - 12.5mm]

Machine screw hex

nut with lock washer

Machine screw

Installation tool:

socket or

screwdriver

(flat or phillips)

Belleville washer

Flat washer

Clearance hole for machine screw:

#10 [M5] machine screw

•

0.19"- 0.28" [4.9mm -7.1mm]

#8 [M4] machine screw

•

0.17"- 0.26" [4.4mm - 6.6mm]

Recommended Surface Preparation:

1. Remove anodization finish

with an abrasive.

2. Apply oxide-inhibiting

joint compound.

Torque to 35 in-lb [4 N-m]

for #8 and #10 screw

1

Stamped Bonding Lugs

EL6CS - Standard Tin-plated Bronze Version with #10 Hardware

EL6CSDB - Direct Burial Tin-plated Bronze Version with #10 Hardware

EL6CS8 - Standard Tin-plated Bronze Version with #8 Hardware

EL6CSDB8 - Direct Burial Tin-plated Bronze Version with #8 Hardware

EL6CSNH - Standard Tin-plated Bronze Version without Hardware

EL6CSDBNH - Direct Burial Tin-plated Bronze Version without Hardware

For 14-6 AWG [1.5 - 16mm² ] Solid & Stranded Copper Conductor

NOTES:

The lug should be installed so that surface contact is maintained for a minimum distance of 0.75 in [19mm] from the edge near the

•

mounting screw. This corresponds to a minimum surface contact area of 0.44 in

²

[284mm

²

]

If available, install the lug at the pre-drilled hole provided on the PV module or framing system. The hole will be identified by a marked

•

"G", "GR", "GROUND", "GROUNDING", or the like.

If no hole is provided, or if the provided hole is not to the recommended diameter, one may be drilled for installation. The hole shall be

•

drilled using a depth restrictor to help prevent damage to the PV modules. A depth restrictor is not required when drilling on the side of

the module, provided the drill path is clear of objects that could be damaged upon penetration of the metal.

After drilling, use an appropiate tool to remove all burrs before installing the lug.

•

For no hardware version, use #8 or #10 screw.

•

EL6CS, EL6CSDB, EL6CS8 and EL6CSDB8 are UL® Listed to UL2703 for use with 125A maximum overcurrent protection.

•

Sizing of an Equipment Grounding Conductor (EGC) and rating of the Overcurrent Protection Device in circuit ahead of the equipment

•

shall not exceed the values in NEC® Table 250.122, where the EGC is only required to be larger than the circuit conductors

supplying the equipment.

For use with a Grounding Electrode Conductor, the size of the conductor shall comply with NEC 250.66 for AC systems and

•

250.166 for DC systems.

WARNING:

1. ERICO products shall be installed and used only as indicated in ERICO product instruction sheets and training materials. Instruction sheets are available at

www.erico.com and from your ERICO customer service representative.

2. ERICO products must never be used for a purpose other than the purpose for which they were designed or in a manner that exceeds specified load ratings.

3. All instructions must be completely followed to ensure proper and safe installation and performance.

4. Improper installation, misuse, misapplication or other failure to completely follow ERICO's instructions and warnings may cause product malfunction, property damage,

serious bodily injury and death.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site must be observed.

Always use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

CADDY, CADWELD, CRITEC, ERICO, ERITECH, ERIFLEX, and LENTON are registered trademarks of ERICO International Corporation.

TECHNICAL SUPPORT

www.erico.com

IP8091 _ N 1 OF 2

INSTRUCTION SHEET

©2010,2011,2012,2013 ERICO International Corporation

NEC is a registered trademark of, and National Electrical Code (NEC) standard is a copyright of the National Fire Protection Association

UL is a registered trademark of UL LLC