Erico, Cadweld, And erico – ERICO Connections to Foot of Continuously Supported Rail and Non-Load Bearing Rail User Manual

Page 3

Refer to the mold tag for applicable instruction sheets.

IPRF_C

www.erico.com

3

ERICO

®

CADWELD

®

AND ERICO

®

CADWELD

®

PLUS Connections to Foot of Continuously

Supported Rail and Non-Load Bearing Rail

!

!

!

!

!

!

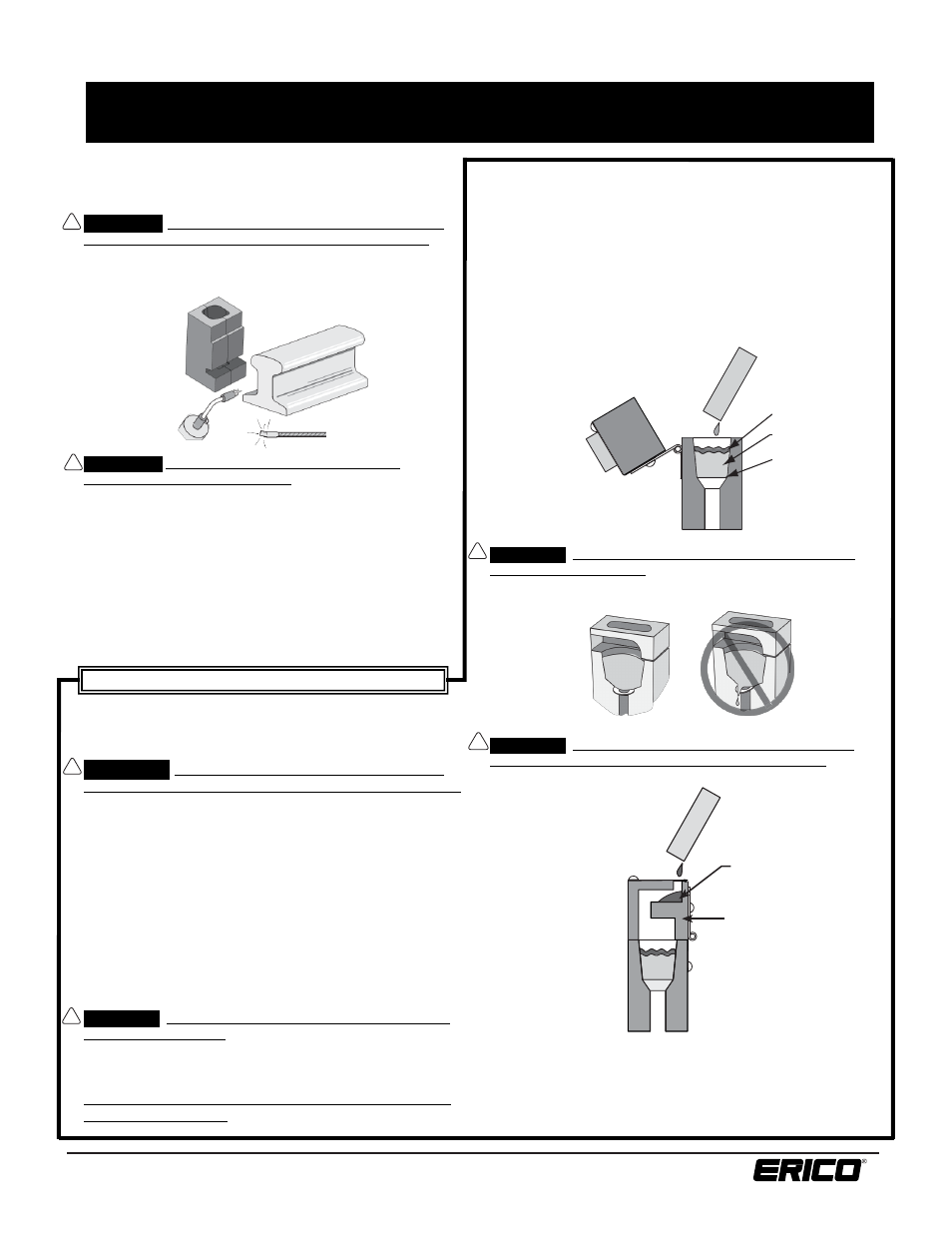

4.

Dry the rail, bond terminal, and mold by heating them to above

250°F (120°C) with a small propane torch.

WARNING:

The rail, bond terminal, and mold must all

be heated above 250°F (130°C) to drive off moisture.

Failure to observe this may result in weld spatter with the

potential for serious burn injury, and an unsatisfactory connection

with excessive porosity. See Figure 6.

WARNING:

Rebonding over the application of an

earlier bond is strictly forbidden! Rebonds must be applied at

least two inches away (centerline to centerline)

from an earlier bond to avoid serious structural harm to the

rail. Failure to observe this may result in a rail break leading

to property damage, injury or death to others.

REFER TO SECTION IV BELOW FOR WELDING

PROCEDURES RELATED TO CADWELD (BLUE TUBE

WITH YELLOW CAP) AND REFER TO SECTION V

BELOW FOR CADWELD PLUS WELDING

PROCEDURES

IV.

WELDING PROCEDURE FOR CADWELD

(Blue Tube with Yellow Cap)

WARNING:

Correctly positioning the mold against the

rail is critical for safety and success in making a connection.

There must be no clearance between the mold that contains the

weld cavity and the rail surface; if a clearance is present or mold is

worn, the mold should be discarded and a new one used. (Molds

can generally be used for up to 50 welds) The exothermic reaction

reaches a temperature in excess of 4000°F, therefore great care

must be exercised to avoid spillage of the molten metal. Failure to

observe this warning may result in molten metal leakage onto the

rail or surrounding areas with the immediate risk of personal injury,

and potentially serious structural damage to the rail.

1. After mold is properly positioned according to the connection-

specific instruction print(s):

CAUTION:

Install only the specified welding material

in the mold crucible. Use only the welding material size that is

specified on the mold. ERICO welding material (F80) is formulated

specifically for use with rail steels.

Refer to instructions provided with the welding material

for more information.

2.

Insert one steel disk, dished (concave) side up, in the crucible

to cover the tap hole.

3.

Dump the contents of the welding material container into the

crucible, being careful not to upset the disk, then carefully tap

the tube on a hard surface to loosen the starting material from

the bottom of the tube and distribute half on top of the welding

material. See Figure 7. Close the mold cover, and pour the

remainder in the opening of the mold cover. See Figures 7

and 9. Failure to comply may result in difficulty getting the

reaction started and/or an unacceptable weld.

CAUTION:

The steel disk must be correctly installed

into the mold crucible. Failure to properly position it may

result in premature leakage into the mold area, resulting in an

unacceptable weld. See Figure 8.

CAUTION:

Avoid direct eye contact with the “flash”

of light from the ignition of the starting material.

4.

Position yourself upwind of the mold, on the field side of the rail.

Place the tip of the flint igniter within one to two inches from the

cover opening, to avoid fouling the flint igniter tip, and ignite.

Remove the igniter quickly to prevent fouling.

FIGURE

6

FIGURE

7

Starting Material

Welding Material

Disk

FIGURE

8

FIGURE

9

Starting Material

Crucible Cover

CADWELD (Blue Tube with Yellow Cap)