Cadweld, Propulsion rail - web bond – ERICO CADWELD Propulsion Rail - Web Bond User Manual

Page 3

Disk

!

!

WARNING:

Back-to-back bonding of web bonds is strictly

forbidden! Bonds made on the opposite side of the rail to

an earlier web bond must be applied at least two inches away

(centerline to centerline) from the earlier bond to avoid serious

structural harm to the rail. Failure to observe this may result in a

rail break leading to property damage, injury or death to others.

IV. WELDING PROCEDURE

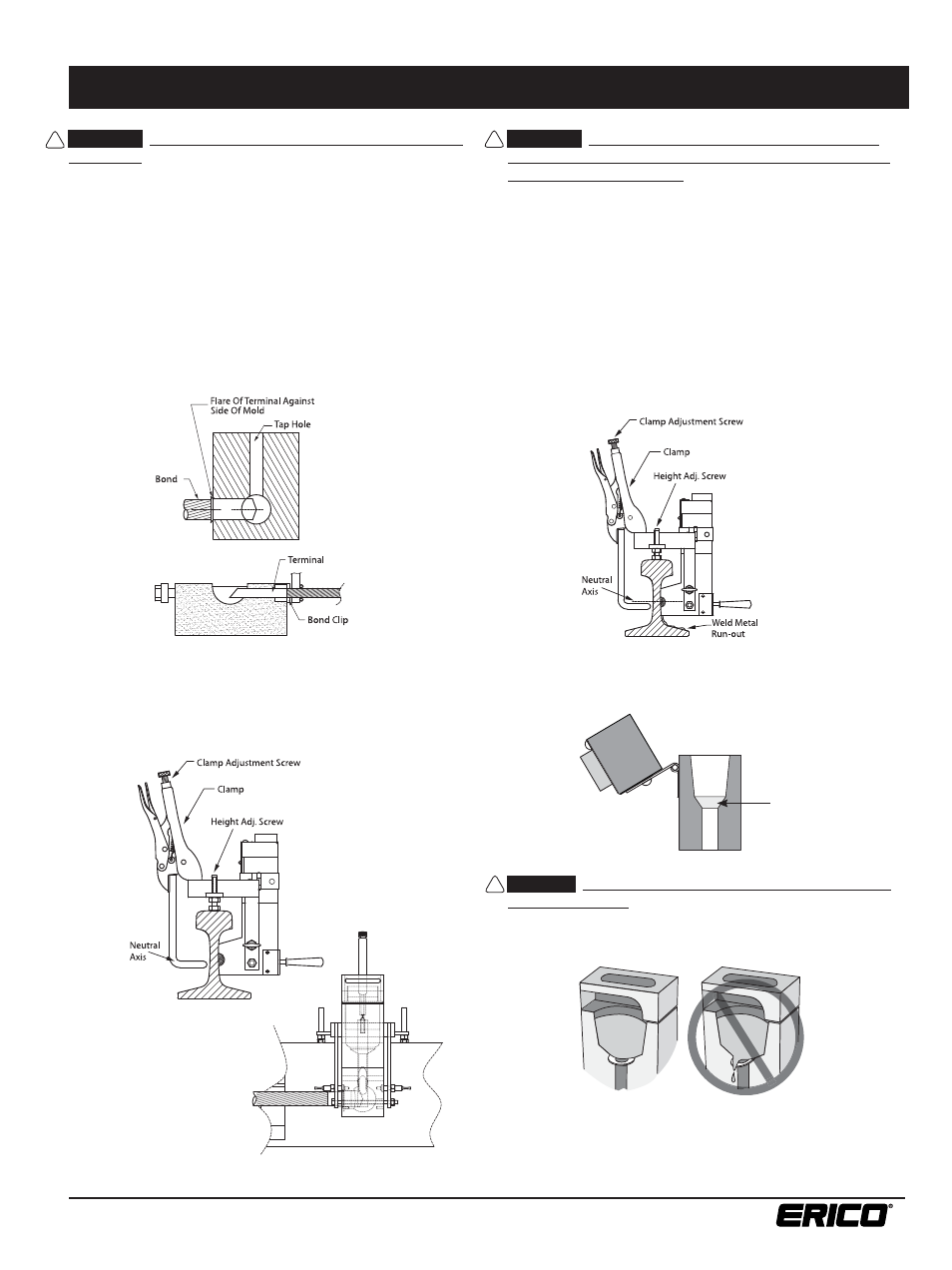

1. Place bond in welder with fl at surface against rail web and

end of terminal against bond clip. This correctly positions

the bond in the weld cavity. Be sure the bond clip is in good

condition and properly positions the terminal under the center

of the tap hole as shown. See Figure 7.

WARNING:

Correctly positioning the mold against the

rail web with the welder device is critical for safety and

success in making a bond. There must be no cracks between

the lower part of the mold that contains the weld cavity and the

rail surface; if a crack is present, the mold should be discarded

and a new one used. See Figure 10. (Molds can generally be

used for up to 50 welds.) The exothermic reaction reaches a

temperature in excess of 4000°F, therefore great care must

be exercised to avoid spillage of the molten metal. Failure to

observe this warning may result in molten metal leakage onto

the rail with the immediate risk of personal injury, and potentially

serious structural damage to the rail. Failure to locate the bond

at the neutral axis of the rail may also contribute to premature

rail damage. Either could result in a rail break leading to

property damage, injury or death to others.

T20-Clamped Position

2. Position the welder with attached mold on the rail.

Use the mold height adjusting screw of the positioning bar

to locate the bond terminal at the neutral axis of the rail.

See Figures 8 and 9.

3. Insert one steel disk, dished (concave) side up, in the crucible

to cover the taphole. See Figure 11.

FIGURE 7

FIGURE 8

FIGURE 9

FIGURE 10

FIGURE 11

www.erico.com

3

CADWELD

®

Propulsion Rail - Web Bond

Refer to the mold tag for applicable instruction sheets.

IPRPW_C

!

CAUTION:

The steel disc must be correctly installed into

the mold crucible. Failure to properly position it may result

in premature leakage into the mold area, resulting in an

unacceptable weld. See Figure 12.

FIGURE 12

4. Dump the contents of the welding material container into

the crucible, being careful not to upset the disk.