Cadweld, Propulsion rail - web bond – ERICO CADWELD Propulsion Rail - Web Bond User Manual

Page 2

!

!

!

!

!

!

!

!

III. PREPARATION

WARNING:

Protect against potential fi re hazards

local to the bonding area and remove all fl ammable

materials from the work area. Notify in advance other

workers in the immediate area that a welding procedure

is about to be done. Failure to do this increases the risk of fi re

with the possibility of property damage, personal injury and death.

NOTE: In case of a fi re involving large quantities of exothermic

welding material, CO

2

or large quantities of water applied from

a distance are required to reduce the spread of the fi re.

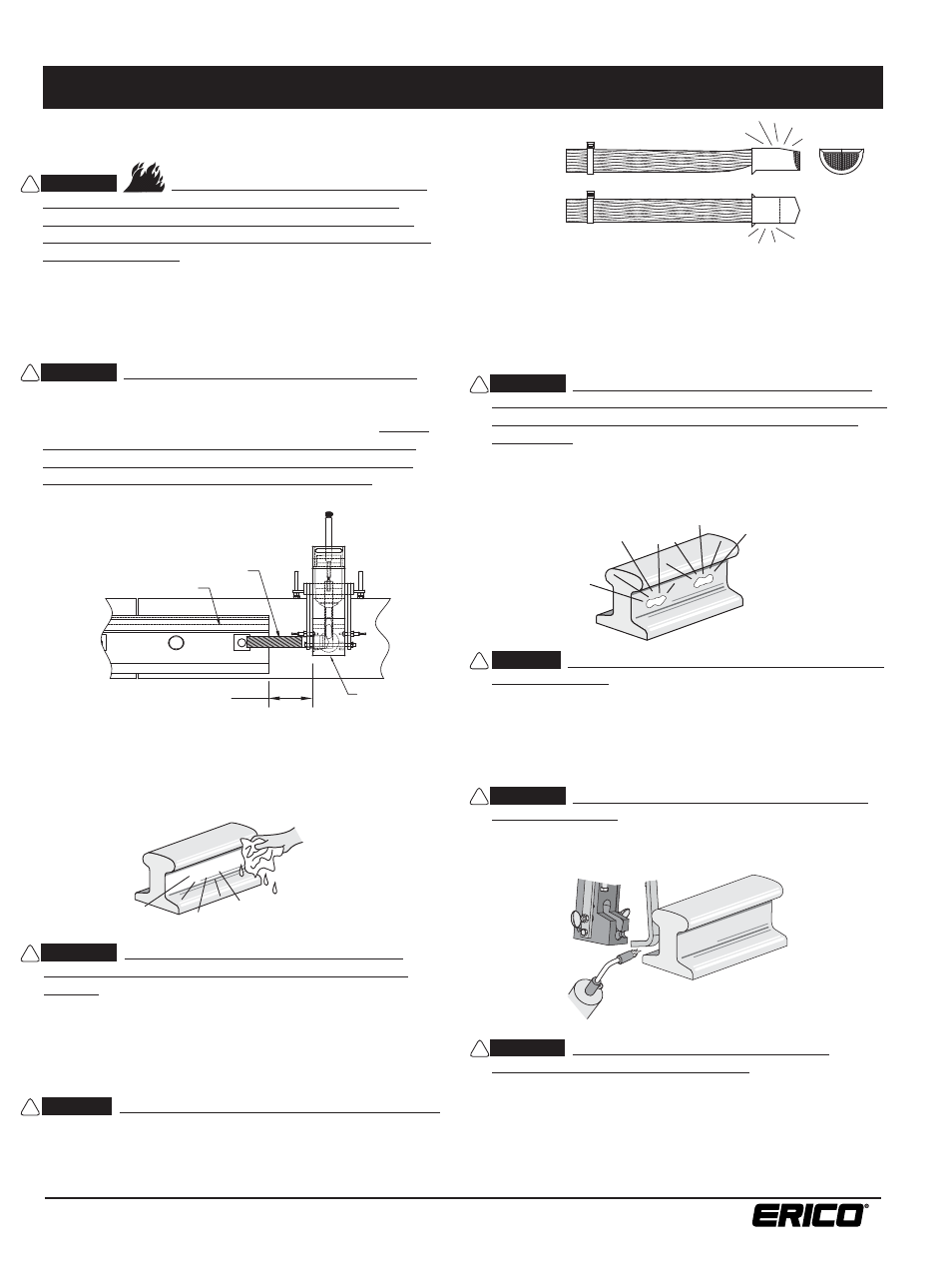

WARNING:

The location of the bond is very important!

Rail track connection web bonds must be made at the neutral

axis of the rail. Failure to observe this may result in a rail break

leading to property damage, injury or death to others. TRACK

CONNECTION BONDING MUST NEVER BE DONE ON OR

NEAR THE HEAD OUTSIDE THE CONFINES OF THE RAIL

JOINT BAR OR NEVER TO THE BASE OF THE RAIL.

See Figure 2.

1. Clean the rail surface and bond terminals. Scrape off excess dirt

and grease, and wipe away any remaining residue using a clean

rag saturated with a railroad approved solvent. See Figure 3.

The cable and rail surface must be dry prior to welding!

Bond

4.00" [102] Minimum

Joint Bar

Mold

& Frame

3. Lightly grind the rail surface using an ERICO approved

grinding wheel that is self-cleaning or a CADWELD

®

brand

Rail Head and Web Cleaner (Part SBB394C). Grinding wheels

with resin binders tend to leave a surface fi lm that may

contaminate the surface, interfering with the achievement

of an optimum bond and causing weld porosity.

WARNING:

The area of the rail web to be bonded must

be lightly ground to a bright fi nish with no visible scratch

marks or gouges (normal uniform fi nishing marks are

acceptable). Failure to observe this may result in visible scratches

or gouges due to overly aggressive grinding that are potential

crack initiators and that may lead to rail breaks causing

derailment accidents with property damage, injury and death

to others. See Figure 5.

CAUTION:

Grinding must not be done more than 4 hours

prior to bonding. If the time lapse is longer, suffi cient

contaminating rust may re-form requiring additional grinding.

Failure to observe this may result in a less than optimum bond.

4. Dry the mold and rail by heating them to about 250°F (120°C)

with a small propane torch.

WARNING:

The rail and mold must both be warmed to

drive off moisture. Failure to observe this may result in weld

spatter with the potential for serious burn injury, and a less than

optimum bond with excessive porosity. See Figure 6.

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

FIGURE 6

WARNING:

The area of the rail where the web bond

will be applied and the bond terminals must be clean

and dry. Failure to comply can cause poor bonding, excessive

weld porosity, and/or spewing molten welding material with

the potential for serious burns to the worker.

2. Use abrasive cloth or wire brush on the bond terminals

if needed to remove surface oxidation.

CAUTION:

The bond terminals must have a bright surface.

Failure to comply with this may result in a less than optimal

weld. See Figure 4.

www.erico.com

2

CADWELD

®

Propulsion Rail - Web Bond

Refer to the mold tag for applicable instruction sheets.

IPRPW_C

WARNING:

Rebonding over the application of an

earlier web bond is strictly forbidden! Rebonds must be

applied at least two inches away (centerline to centerline) from

an earlier bond to avoid serious structural harm to the rail.

Failure to observe this may result in a rail break leading to

property damage, injury or death to others.