Enerpac BMS-Series User Manual

Page 6

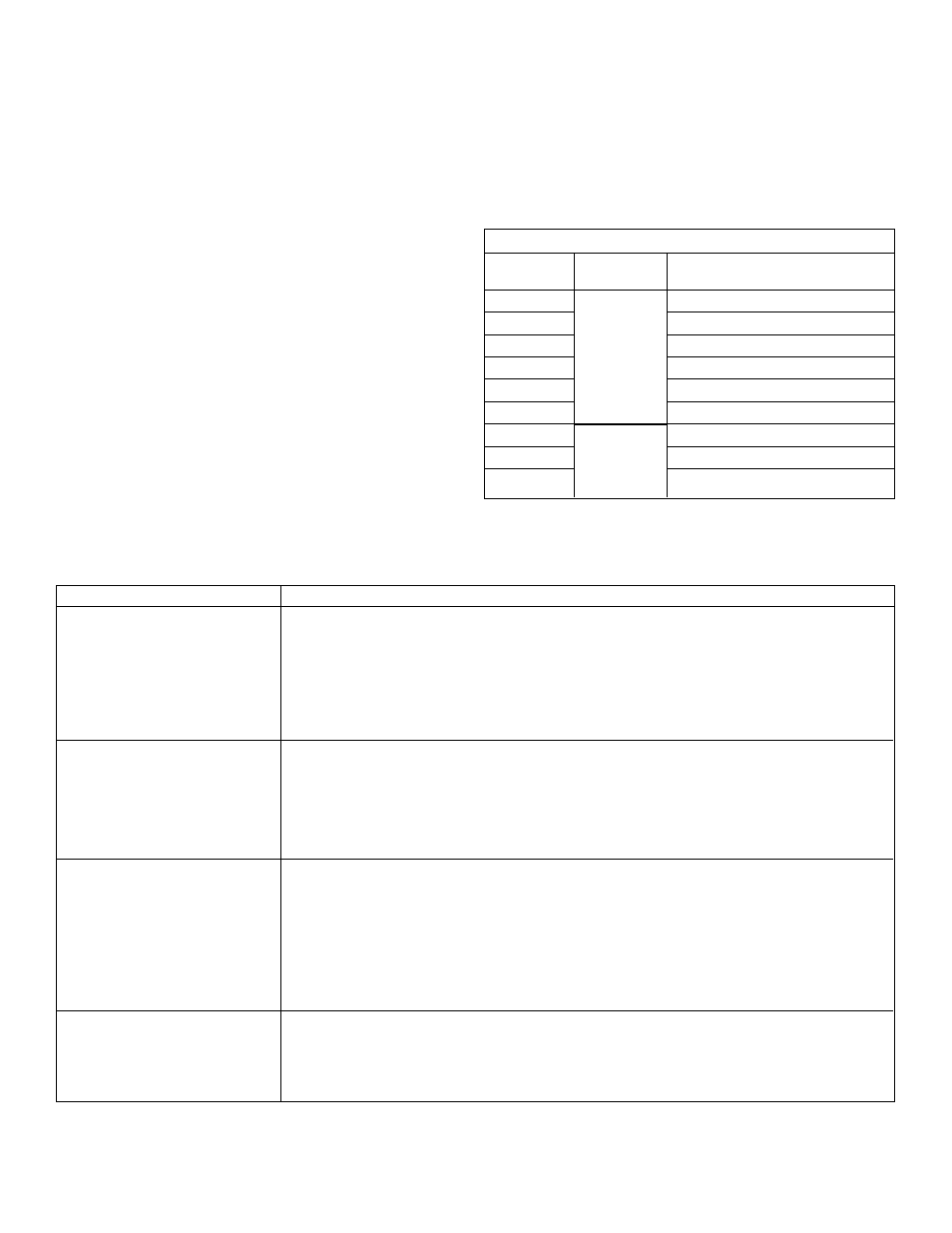

Cylinder will not advance

Cylinder leaks oil

Cylinder will not retract

LEDs of the electronic position

control do not light up

6

2B. RESET SWITCH FOR RETRACTED POSITION: switch is

factory set at the end of retracted plunger stroke. If you want

the plunger movement to stop 3 mm before the end of

retracted stroke, the proximity switch must be moved 3 mm.

3.

Check the correct functioning of the position monitoring by

activating the block cylinder hydraulically. The green LED

indicates the activated switch of the retracted position, the

red LED indicates the activated switch of the extended

position.

4.

Re-assemble the cover plate to the switch box.

6.2 Electric Circuit

See illustration 4 - electric scheme of position monitoring and

Table C - specification proximity switch.

7.0 CYLINDER SPECIFICATIONS

See Table B for clamping force, stroke, oil capacity, etc. and

illustrations 5, 6, and 7 with Table D for cylinder dimensions.

8.0 ACCESSORIES

Contact bolts are available which can be attached to the plunger

end. See Table E for spherical and swivel models.

9.0 MAINTENANCE AND SERVICE

•

Regularly inspect all components to detect any problem

requiring maintenance and service. Replace worn or

damaged parts.

•

Do not exceed oil temperatures above 65 °C.

•

Use clean, high-quality, hydraulic oil in your system.

Contaminated oil causes premature wear to moving parts

and seals. Frequency of changing oil depends on operating

conditions and filters within your system but you should

follow a regular maintenance schedule. Dispose of used oil

properly.

Enerpac offers ready-to-use spare parts kits for repair and/or

replacements.

Table E - Contact Bolts

Model No.

Type

To be used with

cylinder capacities

BS-6

11 kN

BS-8

17 kN

BS-16

44 kN

BS-20

68 kN

BS-30

175 kN

BS-36

275 kN

BR-8

17 kN

BR-16

44 kN

BR-20

68 kN

Spherical

Contact Bolt

Swivel

Contact Bolt

A.

The sequence valve opening pressure is higher than the pump pressure. Adjust the

pressure setting fo the sequence valve.

B.

No oil or too low oil level in pump. Refill reservoir.

C.

Pump release valve open. Close pump valve.

D.

Couplers not completely connected. Check pump valve.

E. Plunger binding. Check cylinder internal parts.

F.

When you use the electronic position control, check if green light (LED) is activated.

A.

Worn or damaged plunger. Replace plunger and seals.

B.

Internal seals damaged. Replace seals.

C.

Leaking or loose oil connections.

D.

O-ring between manifold and cylinder worn or damaged. Check if surface roughness is

Ra 1,6 µm and replace O-ring.

E.

Check if torque of mounting bolts is according to Table A.

A.

Pump release valve colsed. Open this valve.

B.

couplers not completely connected. Check hydraulic line.

C.

Internal damage toplunger. Check parts.

D.

Broken spring. Replace spring.

E.

Back pressure in hydraulic system too high or return-spring is not strong enough.

Reduce back pressure by reducing the number of couplers, increasing the piping

diameter or by-pass the valving.

F.

when you use the electonic positioncontrol, check if red light (LED) is activated.

A.

Check if connections are according to specifications and diagram.

B.

Check the position of the proximity switches (§6).

10.0 TROUBLESHOOTING GUIDE

Problem

Solution