Enerpac ATM-2 User Manual

Page 4

4

7.0 TROUBLESHOOTING

PROBLEM: THE TOOL IS ATTACHED AND

APPEARS TO BE FUNCTIONING

PROPERLY, BUT THE JOINT WILL

NOT ALIGN.

CAUSE:

Hidden obstruction on the joint or

surrounding pipe or the load required

to align the joint is greater than that of

the ATM-2 (i.e. 1 Ton [10 kN] ).

SOLUTION: a. Check the area around the joint for

obstructions.

b. It may be that the required pressure

to align the joint is greater that the

1 ton [10 kN] capacity of the tool.

In this instance another method to

align the joint should be adopted.

8.0 STORAGE

• The ATM-2 should be stored in a cool dry place.

• Machined surfaces are to be smeared with

Mobilgrease XHP ™ 222 Special grease or an

equivalent good quality high load bearing grease.

9.0 APPLICATION DIMENSIONS

Fig 6 Min. and max. flange sizes (visual)

Min. bolt hole size

0.63 inch [16 mm]

Min. distance 0.55 inch [14 mm]

Max. distance 3.23 inch [82 mm]

Hook into this

bolt hole

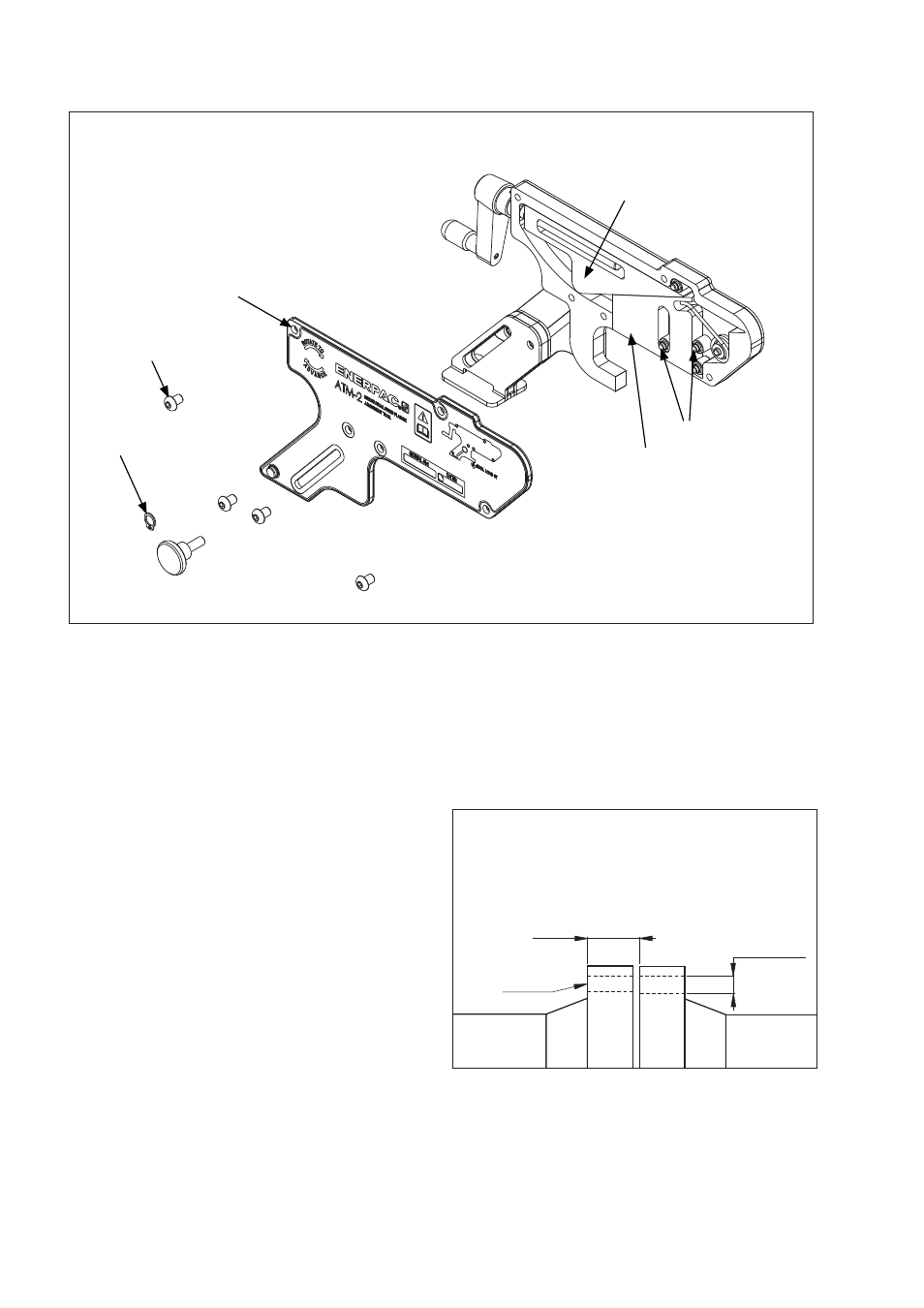

Fig. 5 Inspection and Lubrication

COVER PLATE

HEX SCREW

CIRCLIP

DRIVEN

WEDGE

NEEDLE

BEARINGS

DRIVING WEDGE