Enerpac ATM-2 User Manual

Page 2

2

1.0 RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

safety

first

Read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal

injury or property damage during system operation.

Enerpac cannot be responsible for damage or

injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system

operation. Contact Enerpac when in doubt as to the

safety precautions and applications.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property

A WARNING indicates a potential danger that

requires correct procedures or practices to avoid

personal injury.

2.0 SAFETY ISSUES

Failure to comply with the

following cautions and warnings

could cause equipment damage

and personal injury.

IMPORTANT: Minimum age of the

operator must be 18 years. The operator

must have read and understood all

instructions, safety issues, cautions and warnings

before starting to operate the Enerpac equipment.

The operator is responsible for this activity towards

other persons.

CAUTION: Make sure that all system

components are protected from external

sources of damage, such as excessive

heat, flame, moving machine parts, sharp edges and

corrosive chemicals.

WARNING: Immediately replace worn or

damaged parts with genuine Enerpac

parts. Enerpac parts are designed to fit

properly and withstand rated loads.

WARNING: Always wear safety glasses.

The operator must take precaution

against injury due to failure of the tool or

workpiece

We recommend the use of special

loosening liquids or sprays. Enerpac

hydraulic torque wrenches offer both

square and hexagon drive units to loosen or tighten

bolts and nuts. Enerpac offers nut splitters in case a

nut can not be removed.

WARNING: Never attach the ATM-2 to a

joint until after the flange bolts have been

loosened and removed. Overloading may

occur if bolts are removed while the tool is installed,

and the resulting force is greater than the safe

working load of the tool.

3.0 PRODUCT DESCRIPTION

The ATM-2 Alignment Tool has been developed as

the simple solution to small, low-pressure flange

misalignment.

Misalignment of flange joints often occurs when they

are broken-down for testing, routine maintenance, or

during shutdowns. Also during a construction phase

when new pipe is being installed, final alignment may

be required. Current methods of flange manipulation

tend to be dangerous involving a high degree of

manual lifting and can damage the bolt holes.

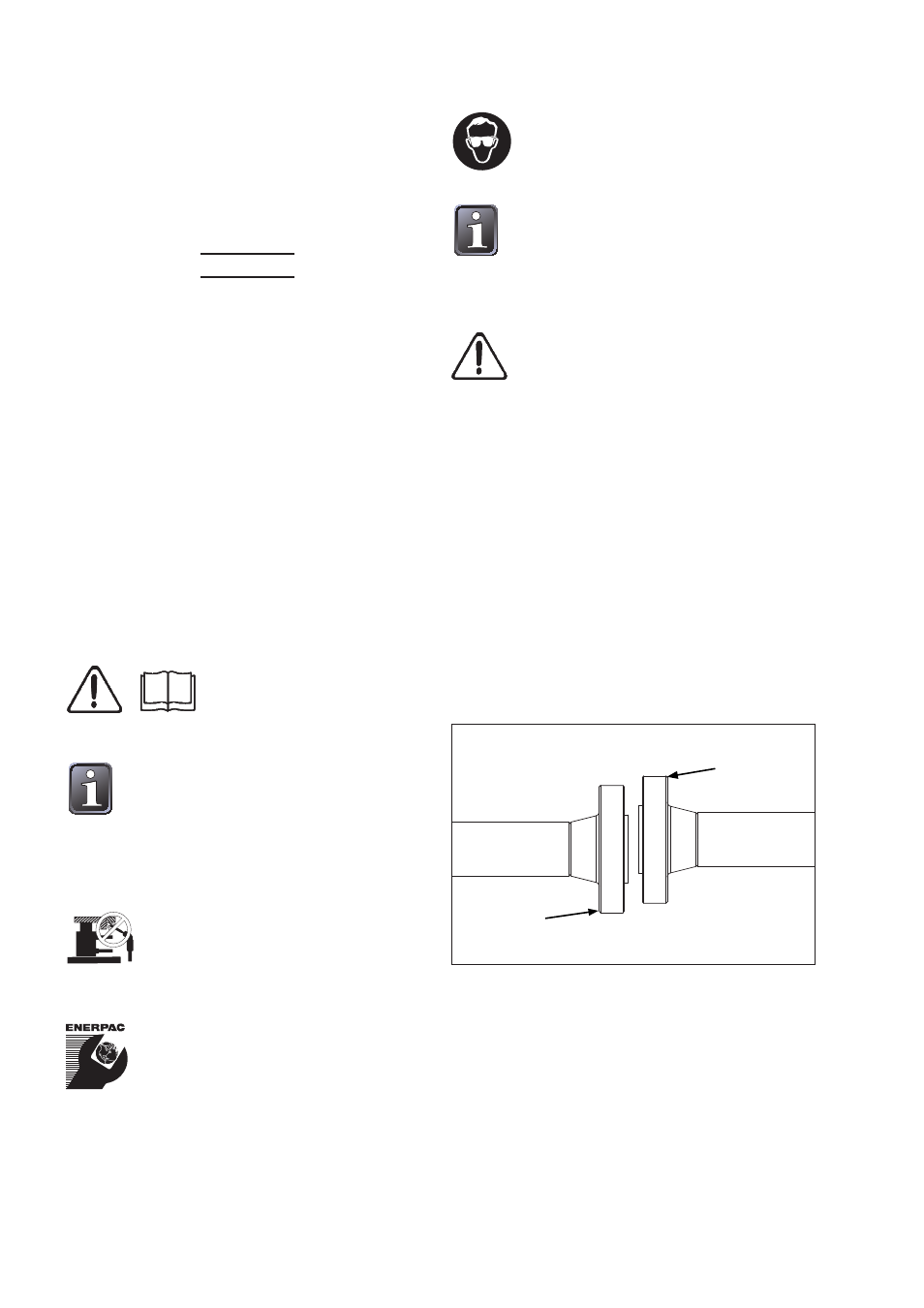

POINT OF MAX.

MISALIGNMENT

POINT OF MAX.

MISALIGNMENT

Fig. 1 A Misaligned Flange Joint

The Enerpac ATM-2 Alignment Tool has been

designed as the simple solution. It is:

• Safe

• Easy to use

• Will not cause damage

• Capable of supplying a 1 ton [10 kN] load

• Can be used on many popular flange sizes