Enerpac ATM-2 User Manual

Page 3

3

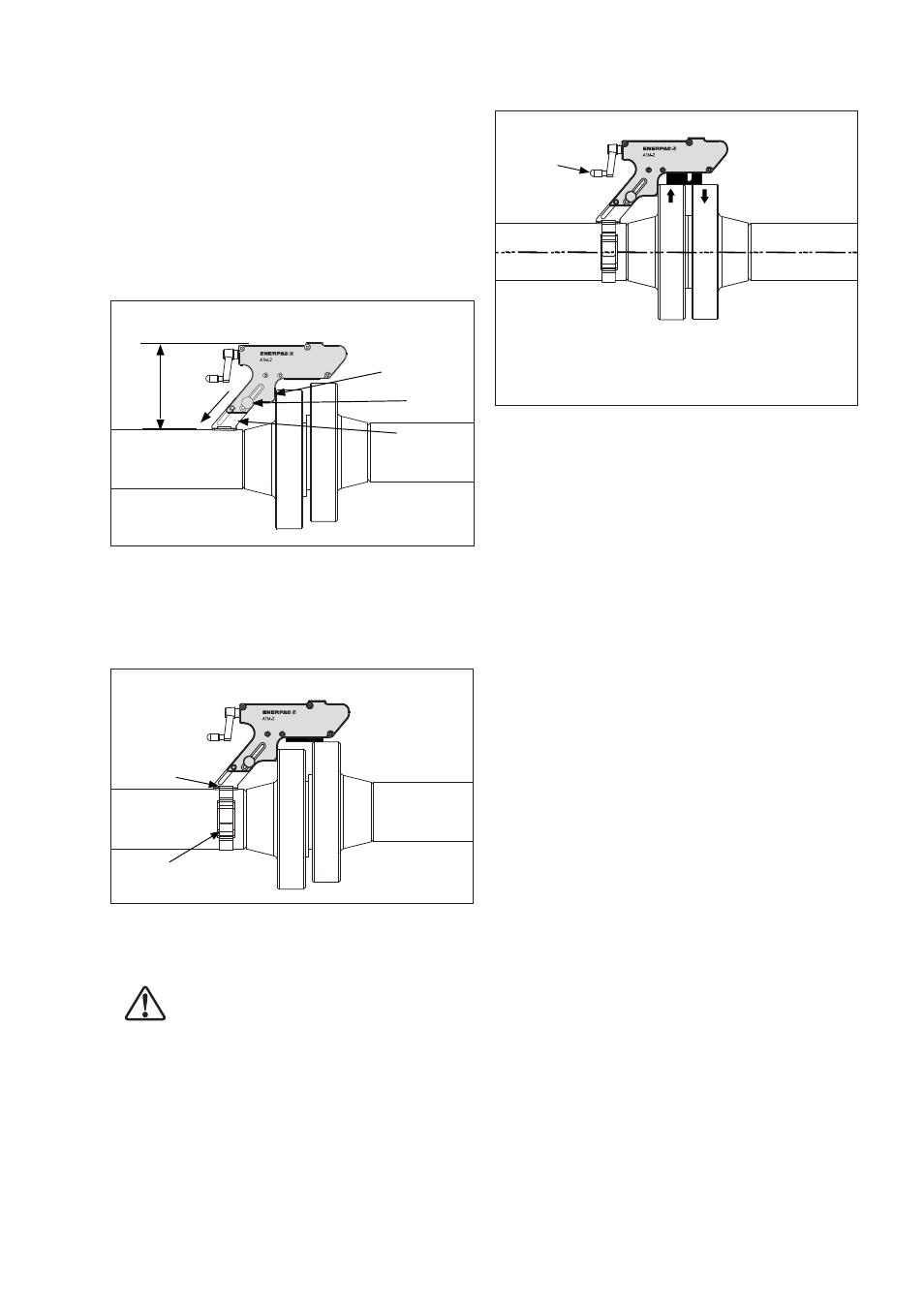

4.0 OPERATING INSTRUCTIONS

1. Determine the maximum point of misalignment.

2. Guide the lift hook of the tool into the bolt hole

at the maximum point of misalignment. The drop

leg should be released and lowered onto the pipe

while the hook is held level in the bolt hole. It then

must be secured in position by tightening the

thumb screw. See Fig. 2.

PARALLEL

Fig. 2 Assembly of Tool on Flange

LIFT

HOOK

THUMB

SCREW

DROP

LEG

3. Rotate the screw handle clockwise until the driven

wedge makes contact with the opposite flange.

Thread the strap through the aperture on the base

of the drop leg, feed the end of the strap through

the buckle, and close the clasp. See Fig. 3.

Fig. 3 Strap Installation

STRAP

APERTURE

STRAP

4. Rotate the screw handle clockwise until alignment

is achieved. See Fig. 4.

WARNING: Do not exceed 45 lbf. [200 N]

hand pressure on the screw handle.

Handle may break if greater force is

exerted. Never use tools to turn the handle.

5. When alignment is completed, the flange bolts

may be inserted and tightened. After replacing all

of the bolts in all open bolt holes (except for the

bolt hole in which the tool lift hook is inserted),

remove the tool by reversing steps 1 through 4.

Fig. 4 Alignment

Maximum Recommended handle-

force = 45 lbf. [200 N].

OPERATE HANDLE BY HAND

ONLY - DO NOT USE TOOLS!

HAND

CRANK

6. After removing the tool from the flange, install the

last flange bolt in the remaining bolt hole.

5.0 EXAMINATION - MAINTENANCE

• After finishing the job and before the tool is placed

back into service, the completeness of the ATM-2

tool must be established and items examined to

ensure that they are serviceable.

• Any missing or damaged items are to be replaced

as soon as possible and prior to the tool being

used again.

• Grease all moving parts regularly with Mobilgrease

XHP ™ 222 Special grease. Refer to Section 6.0.

• Return all items to the carrying case when not in

use.

6.0 INSPECTION AND LUBRICATION

(See Fig. 5 on next page)

STEP 1. Place tool flat on work bench.

STEP 2.

Using a small, flat screwdriver, remove

circlip. Then, remove five 4mm hex screws.

STEP 3.

Remove cover plate and remove any dirt

or corrosion from moving parts.

STEP 4.

Inspect components for wear and damage.

Replace as required. If no damage is

present, then grease and reassemble

parts by reversing steps 1 through 4.

Note: Use Mobilgrease XHP ™ 222 Special grease

or an equivalent good quality high load bearing

grease.