Enerpac SQD-Series User Manual

Page 9

9

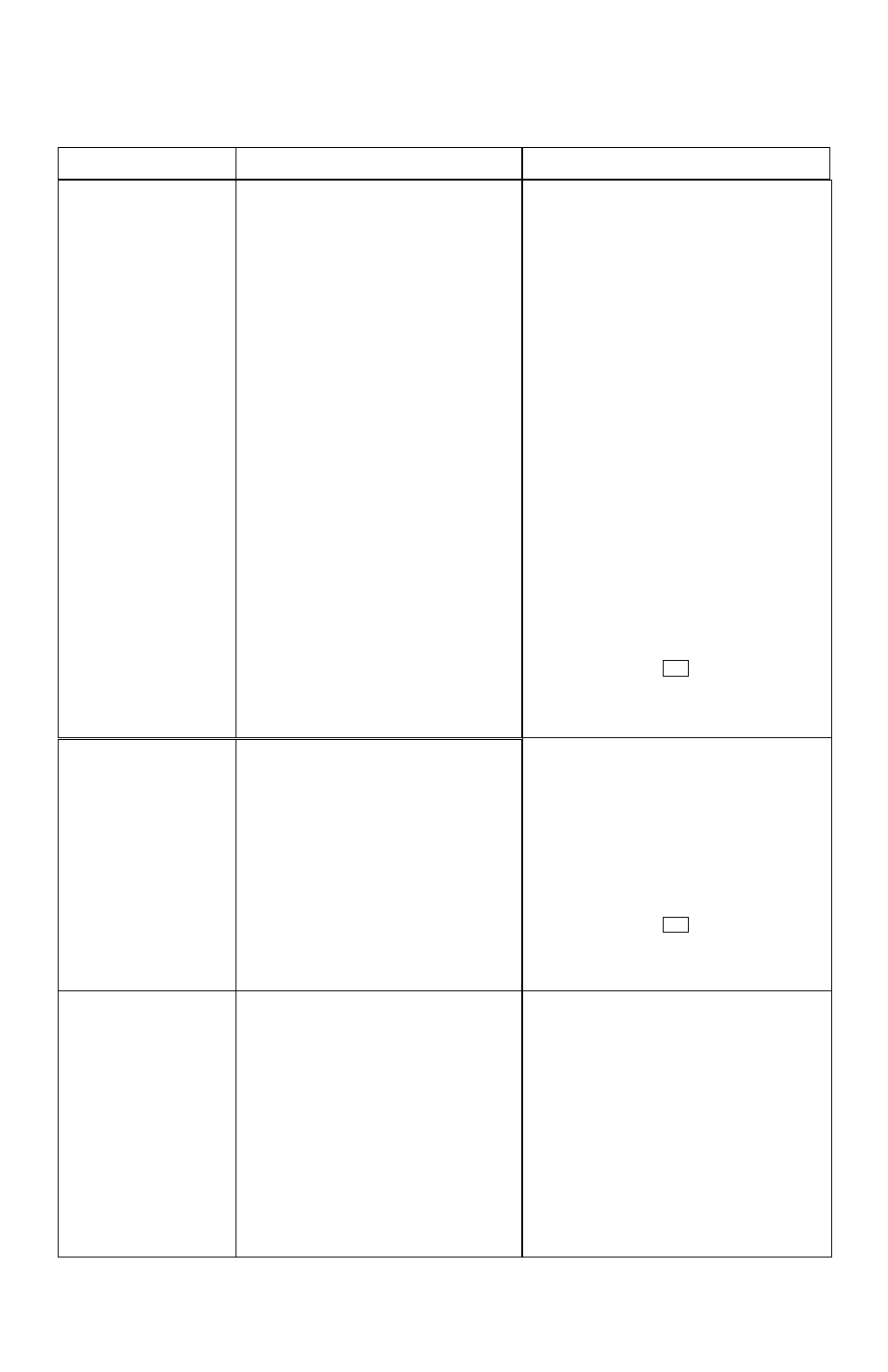

PROBLEM

POSSIBLE CAUSE

1. No pressure

build-up at

wrench, and/or

wrench will not

advance.

A. No power supply or air supply.

B. Pump motor does not rotate

due to wrong voltage supply.

C. Blown out fuses (E-motor)

D. Direction of electric motor

rotation not correct.

E. Couplers at pump and wrench

side not completely

connected.

F. Oil level in pump too low

G. Pressure setting of relief valve

on pump too low.

H. Leakage in pump or wrench.

I. Defective pressure gauge.

J. Incorrectly mounted hoses.

A. Plug in all connections.

B. Check voltage setting

C. Replace fuses.

D. Change wiring of power cable.

E. Depressurize the hoses and

switched off pump, retighten

couplers by hand.

F. Add oil. See pump instructions.

G. Increase pressure by adjusting

pump relief valve. Do not exceed

max. pressure or torque.

H. Determine if leakage is in the

pump or the wrench. Contact your

Enerpac Service Center for

assistance.

I. Connect a second glycerine filled

pressure gauge, adjust pressure

on pump and check both gauge

values.

J. Change hose positions according

to illustration

on page 6: (P to

P) and (T to T).

10

2. Safety valve at

retract side (T) of

wrench opens.

A. Couplers at retract side of

wrench and pump not

completely connected.

B. Incorrectly mounted hoses.

A. When pump is running, use the

remote control to switch the valve

position from (P or A) to (T or B)

and reverse to depressurize the

system. Turn off pump while

switching valve and tighten

couplers by hand.

B. Change hose positions according

to illustration

on page 6: (P to

P) and (T to T).

10

3. Hoses can not

be disconnected

from wrench or

pump.

A. Pressure remaining in double-

acting hydraulic system.

B. Hydraulic system too warm.

A. When pump is running, use the

remote control to switch the valve

position from (P or A) to (T or B)

and reverse to depressurize the

system. Turn off pump while

switching valve and disconnect

hose.

B. Cool the hydraulic system, protect

it against heat and repeat solution

3A above to disconnect hoses.

SOLUTION

7.0 TROUBLESHOOTING

The table below is intended to be used as an

aid in determining if a problem exists.