Enerpac SQD-Series User Manual

Page 6

IMPORTANT: Minimum age of the operator

must be 18 years. The operator is responsible

for the safety of other persons in the vicinity of

the job.

ATTENTION: In case of a interrupted current or

a failure of the pump, switch off the motor and

disconnect the torque wrench from the pump.

DANGER: Do not use electric-

powered pumps in hazardous

environments where explosion-

proof equipment is required.

5.1 Follow all instructions in this section

when:

1. Performing initial operation or start-up.

2. Changing a wrench on same pump.

3. Different torque values are needed, using

the same pump. For instance using

different Allen-key drives on the same

wrench (tables

and

pages 10-11).

5.2 Pump requirements

The advance pressure (P or A) from pump to

wrench must be limited to a maximum 800 bar

[11,600 psi]. The pressure relief valve at the

retract side (B or T) of the pump must be set to

a maximum 120 bar [1740 psi].

IMPORTANT: Maximum oil flow to the torque

wrench: 12 l/min @ 140 bar [732 in

3

/min @

2030 psi] and 2 l/min @ 800 bar [122 in

3

/min @

11600 psi].

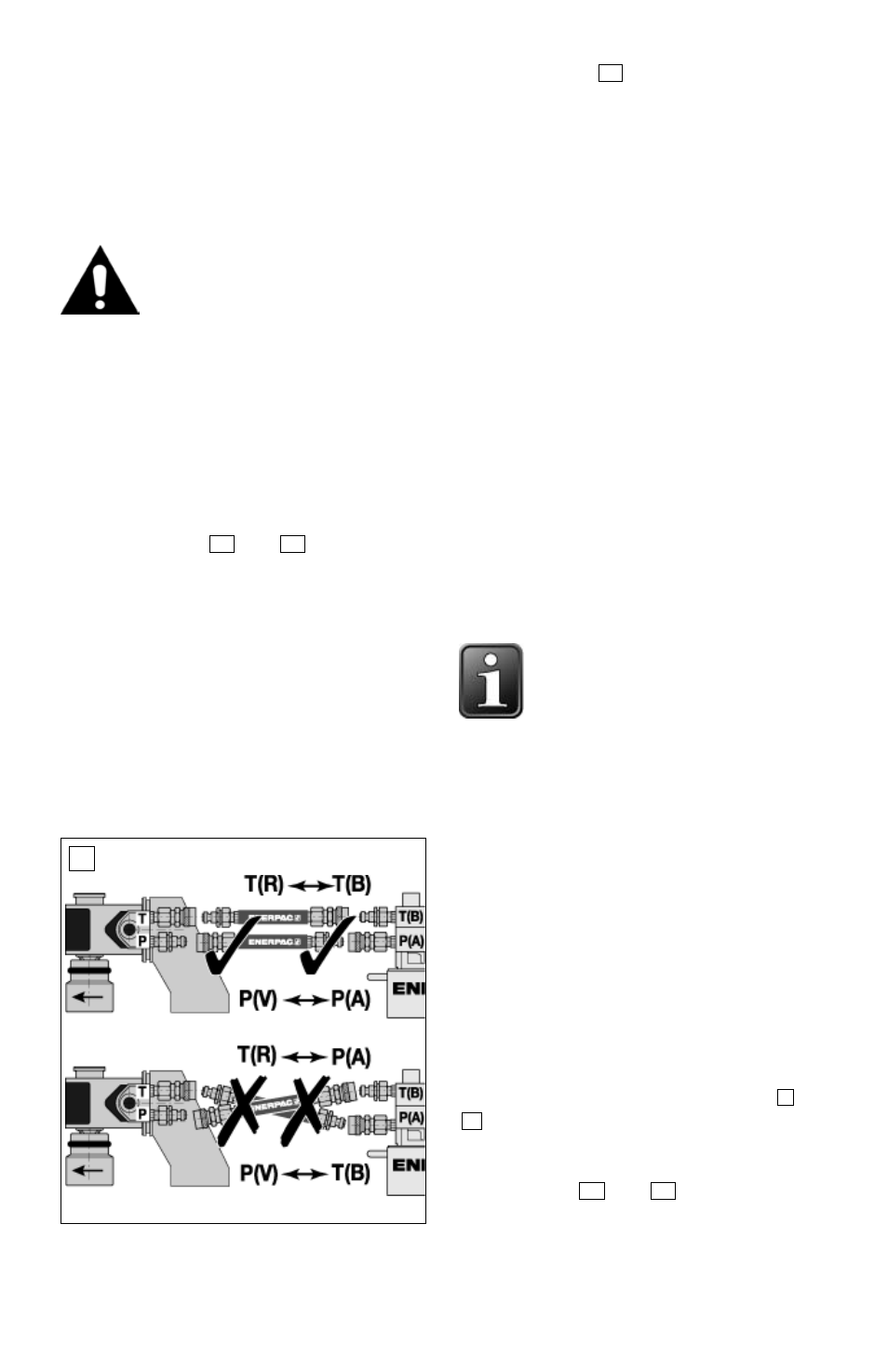

CAUTION: See

. Make sure all couplers

and hoses are fully connected and oil can flow

freely from (P to P) and (T to T). Incorrectly

mounted couplers can still be closed, with the

result that oil on the retract side (T or R) can be

pressurized by the advance side (P or V). The

safety valve in the retract side (T or R) of the

wrench (2) will open and vent oil to prevent

over-pressurization. This valve is factory set at

225 - 300 bar [3,260 - 4,350 psi].

5.3 Bleeding air from the system

During first-time operation, the hydraulic

system is filled with air. Remove air by

connecting the THC-700 series hoses to each

other and cycling the pump using the remote

control. If the torque wrench is connected, air

can also be removed by cycling the wrench

several times.

5.4 Pressure and torque setting

Read the pump instructions. Without placing

the wrench on the bolt or nut, operate the

pump in the advance direction.

IMPORTANT: Before using the

pump with the torque wrench on a

bolt or nut make a functional test

at maximal 100 bar [1,450 psi].

Set the required torque by adjusting the

pressure relief valve on the advance side (P) of

the pump and reading the value on the

pressure gauge.

When making bolted connections always

consult the manufacturers instructions or the

engineering recommendations.

Pressure setting can be adjusted between 40 -

800 bar [580 - 1,1600 psi]. Adjust the pressure

relief valve setting by turning the spindle on the

pump:

• clockwise = higher pressure (torque)

• counter-clockwise = lower pressure (torque)

Set the torque by consulting the tables

and

on pages 12-14 in this instruction sheet, or

torque versus pressure chart included with

each wrench. When using Allen-key drives

consult tables

and

on pages 10-11 for

max. allowed torque.

A2

A1

C

B

10

A2

A1

6

10