Enerpac SQD-Series User Manual

Page 8

ATTENTION: Socket or Allen-key drive should

not be rotating during retract cycle.

IMPORTANT: After reaching the preset

pressure (torque), the torque wrench will no

longer rotate while the gauge will read the

preset pressure value. Monitor the pressure

gauge on the pump to verify that the bolt/nut

connection has been tightened to the preset

torque values.

If a bolt or nut does not loosen, the torque

(pressure) may be increased. Do not exceed:

• maximum torque for the bolt size to avoid

danger of bolt-shearing;

• maximum pressure (torque) for the Allen-

key drive (hexagon insert) to avoid danger

of bolt-shearing and Allen-key drive failure.

Maximum torque of Allen-key drives are

specified on pages 10-12.

•

maximum pressure 800 bar [11,600 psi];

WARNING: Exceeding the maximum

torque for a bolt size or Allen-key

drive will result in bolt-shearing and

potential parts failure. These failures could result

in bolt or Allen-key drive pieces being projected

from the wrench or bolting site. Failure will also

result in the torque wrench unit moving rapidly

away from the torquing point causing potential

injury to the operator.

IMPORTANT: Misuse resulting in

broken or damaged Allen-key

drives, square drives, or internal

components of the wrench, or personal injury,

are not covered under Enerpac's Warranty

policy. Maximum torque of Allen-key drives

are specified in tables

and

on pages

10-11.

We recommend the use of special

loosening liquids or sprays.

Enerpac offers nutsplitters in case a

nut can not be removed.

6.0 MAINTENANCE AND SERVICE

IMPORTANT: To safeguard the

accuracy of the torque values, the

torque wrench and pressure gauge

on the pump must be checked on a

regular basis. Contact Enerpac for calibration.

Repairs must be made by Enerpac or an

authorized Service Agent, as after an exchange

of parts, the accuracy of the torque and the

wrench functions must be checked.

Maintenance is required when wear and/or

leakage is noticed. Regularly inspect all

components to detect any problem requiring

service and maintenance. Contact your Enerpac

representative for repair and/or replacements.

To prolong the life of your torque wrench

equipment, follow the points below:

• Do not exceed oil temperature of 150˚F (65˚C).

• Regularly check the pumps’ oil level and

condition. Consult pump instructions.

• Follow the lubrication scheme in section 6.1.

• Lubrication may influence torque accuracy

and life-time of the wrench. Always clean

and lubricate after usage and store in the

carrying case.

6.1 Lubrication

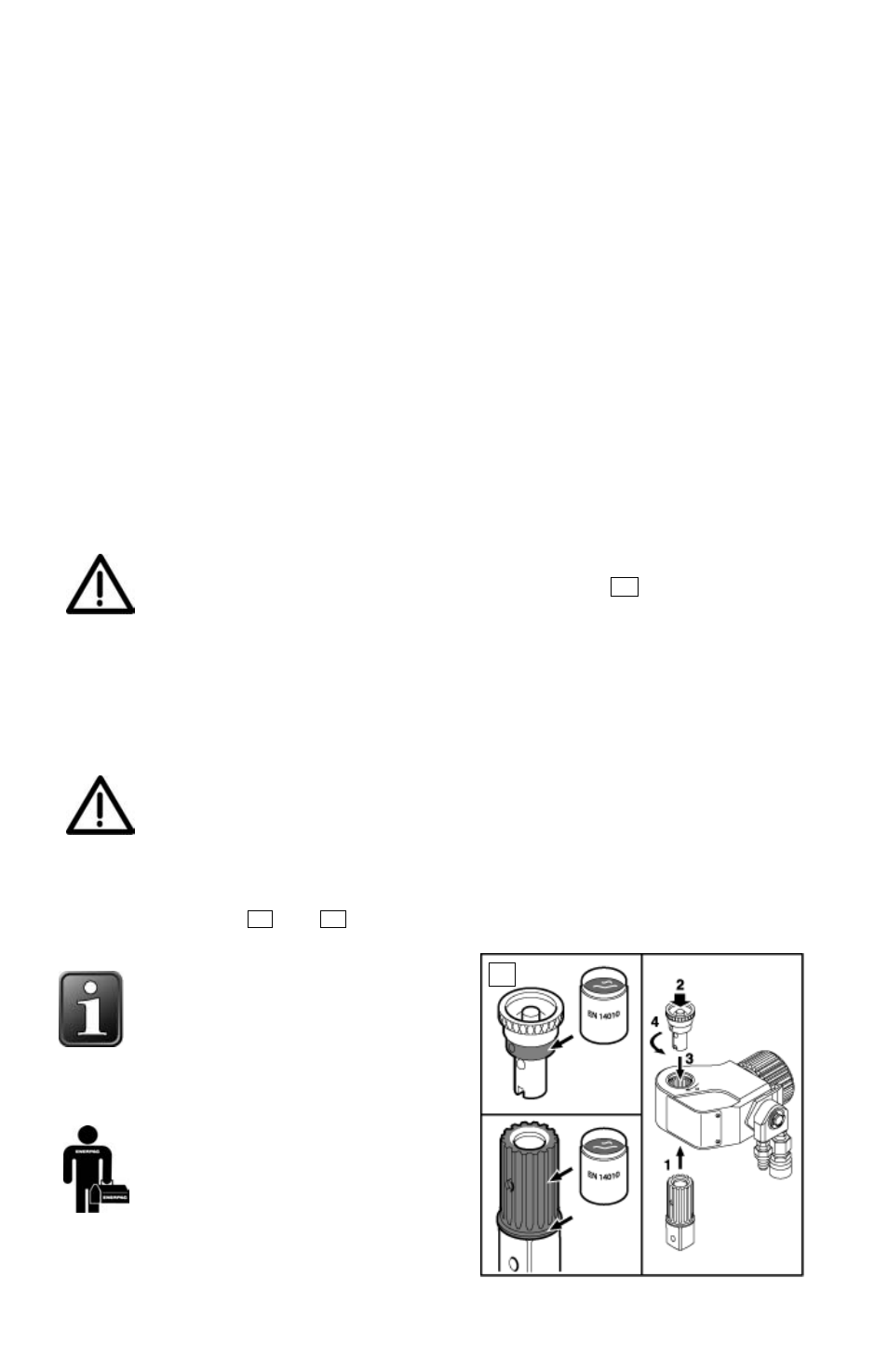

Review illustration

. below. Note areas that

are to be cleaned and lubricated on a regular

basis. Follow step 1-4 to re-assemble drive

mechanism after lubrication is completed.

• Clean surface and grease with Gleitmo 805

only. Available at Enerpac as Torque

Wrench Grease EN-14010.

• Keep all other surfaces clean and dry. Do

not lubricate.

IMPORTANT: Do not disassemble the wrench

unit (1) or the drive release (5). Do not immerse

these parts in oil, kerosene or other cleaning

liquid to prevent dirt from flushing in and

grease from being dissolved.

14

A2

A1

8

14