Ac b – Enerpac GBJ-Series User Manual

Page 6

6

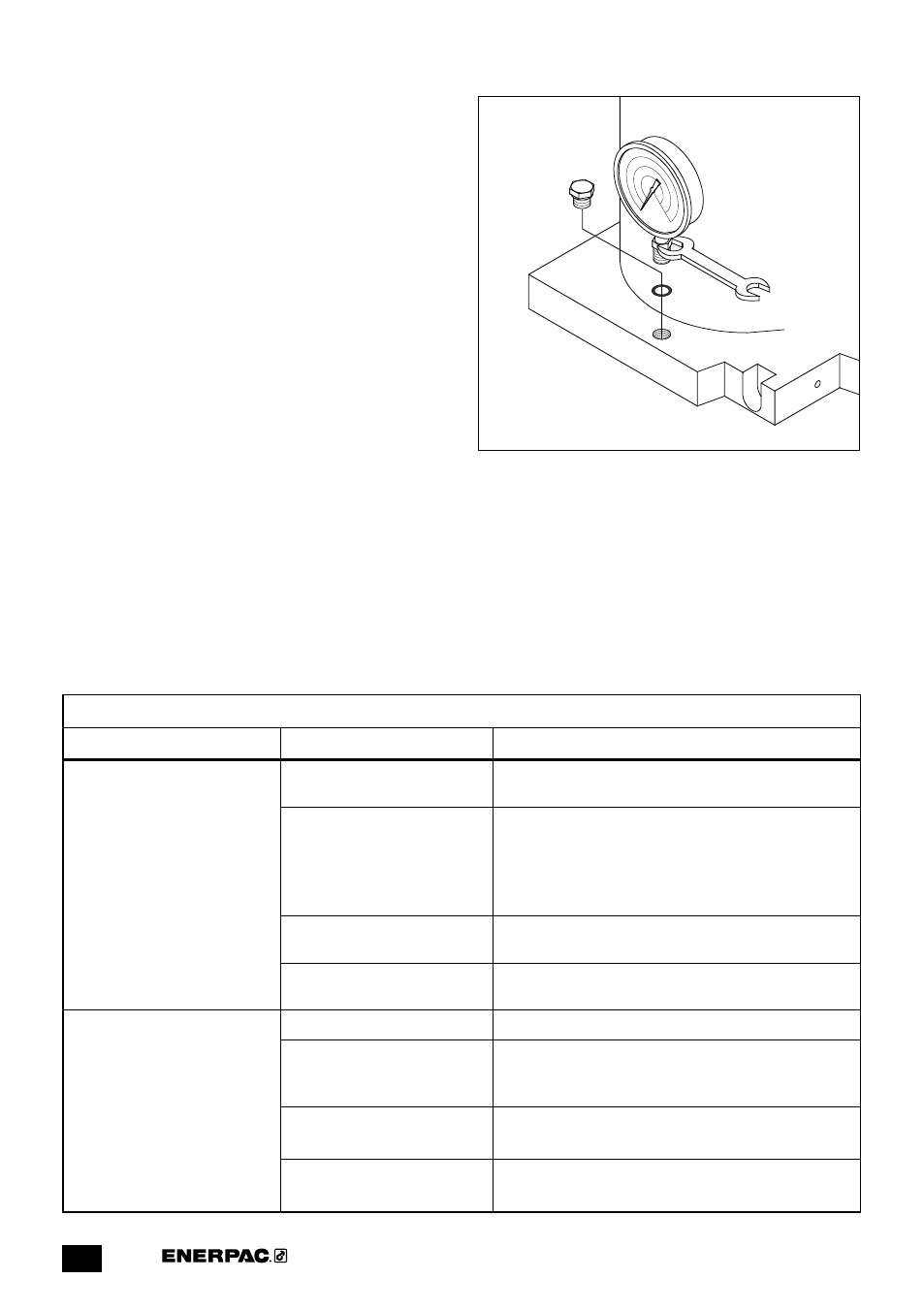

9.0 PRESSURE GAUGE INSTALLATION

(GBJ-100 ONLY)

A pressure gauge is used on Model GBJ-100 only. The

gauge is shipped loose and must be installed prior to

jack operation. See Fig. 9.

Install the gauge as described in the following steps:

1. Be certain that the ram is fully retracted and that no

load is placed on the saddle.

2. Using a 17 mm open-end wrench, remove shipping

plug (A) from gauge port.

3. Be sure that O-Ring (B) is seated at the bottom of the

threaded port.

4. Position the gauge (C) over the port with the dial

facing out, toward the user.

5. While fi rmly holding the gauge housing so that it does

not move, thread the gauge swivel fi tting into the port.

Tighten the fi tting by hand using a 22 mm open-end

wrench.

IMPORTANT: To prevent damaging the O-Ring, do not

use a wrench extension when installing the gauge.

10.0 TROUBLESHOOTING

Refer to the troubleshooting table for a list of common

bottle jack symptoms, possible causes and solutions.

For repair service, contact an Enerpac Authorized

Service Center. Inspection and repairs should be

performed only by an Enerpac Authorized Service

Center or other qualifi ed hydraulic service facility.

TROUBLESHOOTING TABLE

SYMPTOM

POSSIBLE CAUSE

SOLUTION

1. Erratic action.

Air in system.

Bleed air from unit. Refer to Section 6.2 for air

bleeding instructions.

Hydraulic oil viscosity too

high.

Drain all old oil from the reservoir. Refi ll to proper

level with Enerpac Type HF hydraulic oil (ISO

Grade 32). Refer to Section 6.1.

IMPORTANT: Dispose used oil in accordance with

all applicable laws and regulations.

Ram sticking or binding.

Remove any dirt or gummy deposits from jack. Be

sure that jack is not misaligned under load.

Seal wear and/or internal

damage.

Have jack inspected and repaired by Enerpac

Authorized Service Center.

2. Ram does not advance.

Release valve is open.

Close release valve.

Low oil level.

Fill reservoir to the proper level with Enerpac Type

HF hydraulic oil (ISO Grade 32). Refer to Section

6.1.

Jack hydraulic circuit is air

locked.

Bleed air from unit. Refer to Section 6.2 for air

bleeding instructions.

Load is greater than

capacity of jack.

Use a higher capacity jack of appropriate load

rating.

A

C

B

Fig. 9 - Gauge Installation (GBJ-100 Only)