Ok no no – Enerpac GBJ-Series User Manual

Page 4

4

Note: Model GBJ-100 should not be used in the

horizontal position.

6.0 MAINTENANCE

6.1 Adding Hydraulic Oil

If oil level is low, add additional oil as described in the

following steps. Be careful to avoid dirt entry during

fi lling.

1. With ram fully retracted, set the jack in the upright

position. Be sure surface under jack is level.

2. Remove the oil fi ll/air release plug. On all jacks except

model GBJ-100, the plug is located on the side of the

cylinder housing. On model GBJ-100 only, the plug is

located at the top of the cylinder housing.

IMPORTANT: Use only Enerpac HF Series hydraulic oil

(ISO Grade 32) poured from a clean container.

WARNING: The use of motor oil, brake fl uid,

alcohol, glycerin, vegetable oil or other

unapproved fl

uids will damage the jack,

resulting in possible failure or malfunction of the device.

Personal injury and/or property damage may occur.

3. All models except GBJ-100: Fill until oil level is even

with bottom edge of the oil fi ll hole. See Fig. 6.

4. Model GBJ-100 only: Fill until oil level is about 3

inches [75 mm] below the oil fi ll hole. See Fig. 7.

5. Continue operating the pump handle as required to

raise load to the desired height.

6. Model GBJ-100 only: After load is partially raised and

pumping eff ort noticeably increases, move the pump

handle to the high pressure pump. Continue pumping

until the load is raised to the desired height.

WARNING: Model GBJ-100 is equipped with a

pressure gauge calibrated to indicate the

approximate weight being lifted. STOP pumping

immediately if the gauge reading exceeds 100 metric

tonnes [980 kN]. The jack is not designed to lift loads

greater than 100 metric tonnes (110 short tons).

7. Immediately after lifting is completed, support the

load with jack stands of the appropriate weight rating.

5.3 Lowering the Load

1. Operate pump handle one or two strokes, so that

the load is raised off of the jack stands. Remove jack

stands from under the load.

WARNING: Turn the release valve slowly in the

following step. If release valve is opened too

quickly, the object being lowered may drop

suddenly, possibly causing the jack to become

dislodged from beneath the load. Serious personal injury

and/or property damage could result.

CAUTION: Avoid “shock loads” created by

quickly opening and closing the release valve as

load is being lowered. Shock loads may overload

the jack’s hydraulic circuit and damage the jack.

2. Using rectangular end of pump handle, slowly turn

the release valve stem counter-clockwise until the

valve opens and the ram begins to retract (do not turn

more than two revolutions). Allow the ram to continue

retracting until the load is fully lowered.

3. Remove jack from the lifting area.

4. Press down on the ram to return it to the fully retracted

position. Turn the extension screw (if equipped) all

the way down so that threads are fully recessed and

protected from damage.

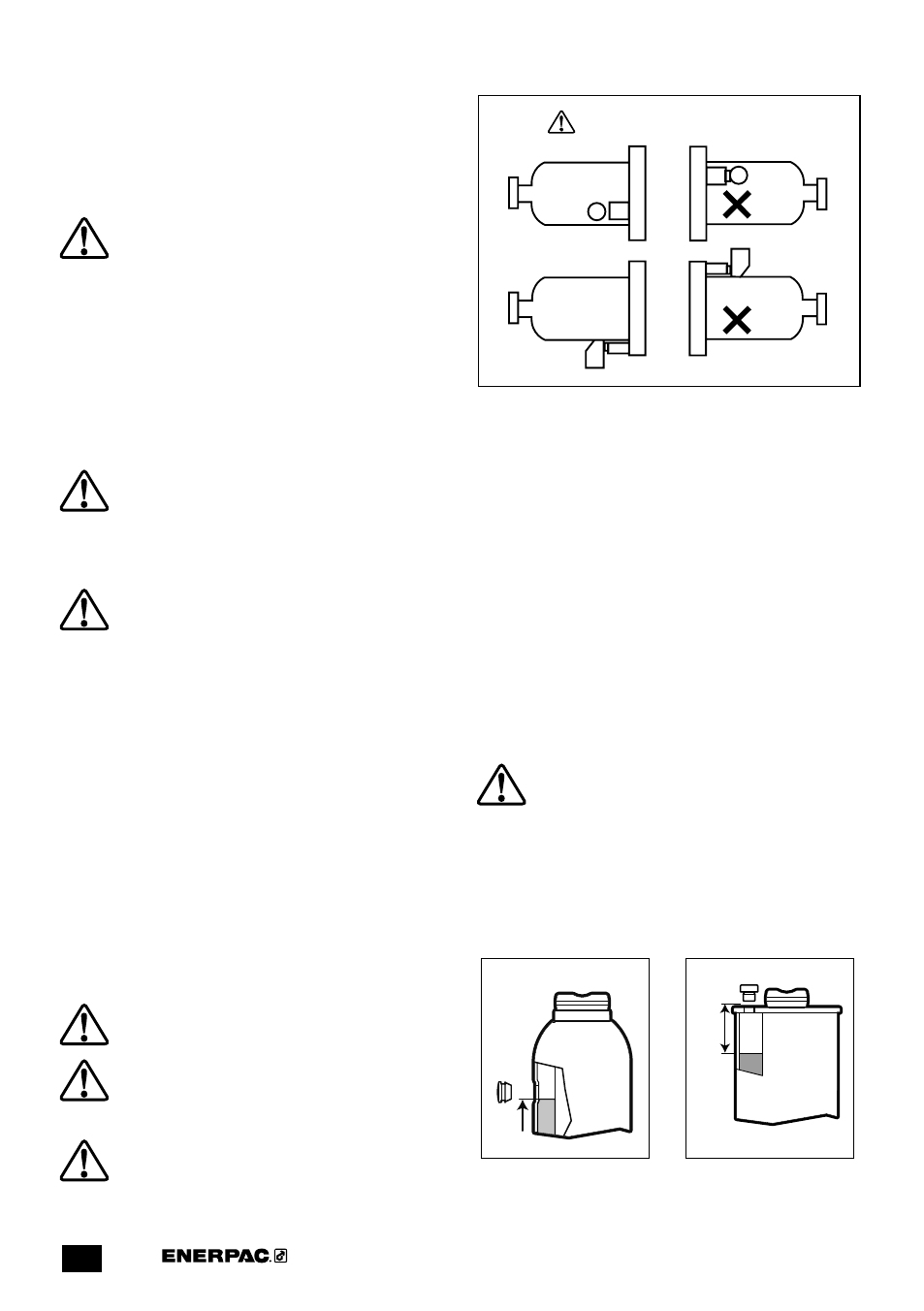

5.4 Horizontal Operation (all models except GBJ-100)

When operated horizontally, the jack must be oriented

so that the pump is positioned down - closest to the

ground. The jack will not operate properly if the pump

is positioned up. See Fig. 5 for horizontal operating

positions.

WARNING: Support the jack during horizontal

operation so that it does not drop.

WARNING: Jack capacity is 50 percent or less

than normal rating when operated horizontally.

Use care to ensure that jack is not overloaded

during horizontal operation.

WARNING: Always use appropriately rated

blocking and/or supports to retain objects that

have been pushed apart and/or that are under

tension. Never place your hands, feet or body in between

objects being supported only by the jack.

3 inches [75 mm]

Fig. 6 - Oil Level,

all models

except GBJ-100

Fig. 7 - Oil Level,

Model GBJ-100 only

Fig. 5 - Horizontal Operation (all models exc. GBJ-100)

Do NOT exceed 50% of the jack's rated

capacity during horizontal operation.

OK

OK

NO

NO