Warning, Caution – COATS 5035 A/E Tire Changer User Manual

Page 16

MAINTENANCE INSTRUCTIONS

Read and follow all the maintenance instructions

provided in this manual to keep the machine in good

operating condition. Refer to the other materials

received with the unit and to the service bulletins

from the manufacturer for additional instructions on

proper maintenance and service. Regular

inspections and proper maintenance are essential to

preventing accidents and injuries.

Before making any

inspection, adjust-

ment, or repair, dis-

connect the power source and block out all mov-

ing parts to prevent injury.

Keep the machine

and the immediate

work are clean. Do

not use compressed air to remove dirt and

debris from the machine. Foreign material may

be propelled into the air and into operator or

bystander causing personal injury.

Wear protective cloth-

ing and use eye pro-

tection when making

any adjustments or repairs to the machine.

A. The vertical slide should be cleaned with a

vaporizing solvent and then lubricated with

chassis grease once a month.

B. Check the adjustment of the mount/demount

head once a month. See instructions this page.

C. Check the fluid level in the table top

transmission once every 3 months. If fluid

shows on dipstick, level is satisfactory. If no fluid

shows, add an SAE 80 gear lubricant until fluid

shows on dipstick.

D. The table top, clamps, mount/demount head,

and other working surfaces should be cleaned

with a vaporizing solvent every month.

E. The clamps should be inspected and metal

chips and dirt removed from the serrations once

a month.

F. Check the tire pressure gauge function daily,

and check the accuracy monthly. Use a

pressurized tire and a high quality stick-type

pressure gauge. If necessary, adjust the dial of

the machine gauge. If the gauge is defective,

replace it immediately (part number 107985).

Check function of the pressure limiter weekly.

G. Make sure all fasteners are securely tightened.

H. make certain that all guards and covers are in

place.

I.

Check for worn, damaged or missing parts

including grips and protective covers. Replace

them before allowing the unit to be used.

J.

On a daily basis, inspect the unit and check to

be certain that all systems are operating

normally. Detailed inspection and testing

procedures are specified for various

components at regular intervals. Set up a chart

and assign responsibility for these items.

Replace any damaged

or missing safety

decals.

IMPORTANT: These instructions will help you

service the unit. Instructions are for a person with

some mechanical ability and training. No attempt

has been made to describe all basic steps. For

example, how to loosen or tighten fasteners. Also

basic procedures such as cycling systems and

checking operation of the equipment are not fully

described since they are known to anyone who does

mechanical and service work. Do not attempt to

perform work beyond your ability or at which you

have no experience. If you need assistance, call an

authorized service center.

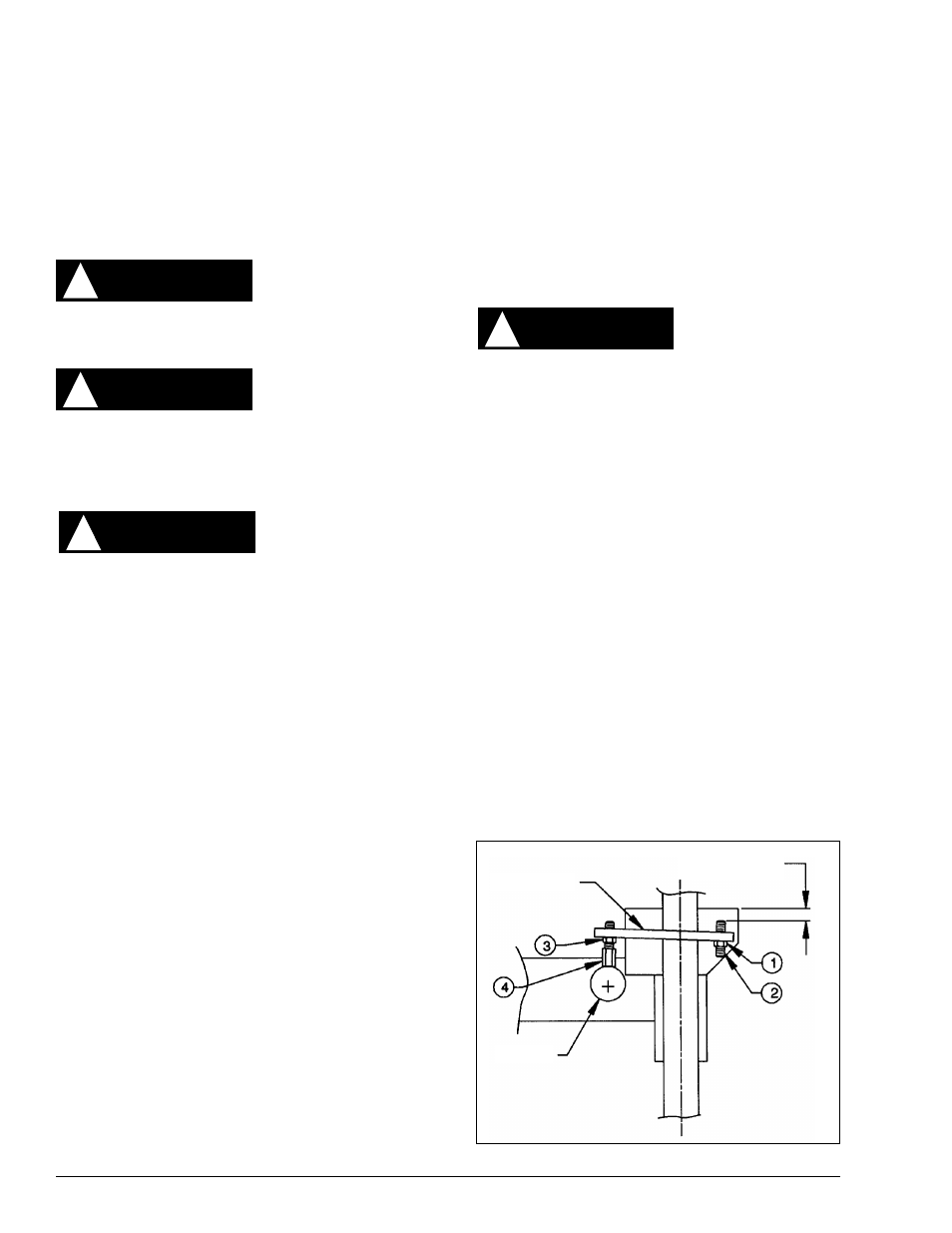

Mount/Demount Tool Head Adjustment

To Adjust Tool Head Lift

Loosen jam nut (ref. 1) and adjust screw (ref. 2) until

lift clearance is 1/8" to 3/16". Tighten jam nut and

check.

To Adjust Lock Tightness

With lock handle unlocked, loosen jam nut (ref. 3)

and adjust pin (ref. 4) until a slight firmness is

obtained, then tighten jam nut and check. Also

recheck tool head lift at this time.

14 • 5035 A/E Rim Clamp Tire Changer

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

Lock Plate

This will be the

same as tool head

Cam