COATS 5035 A/E Tire Changer User Manual

Page 12

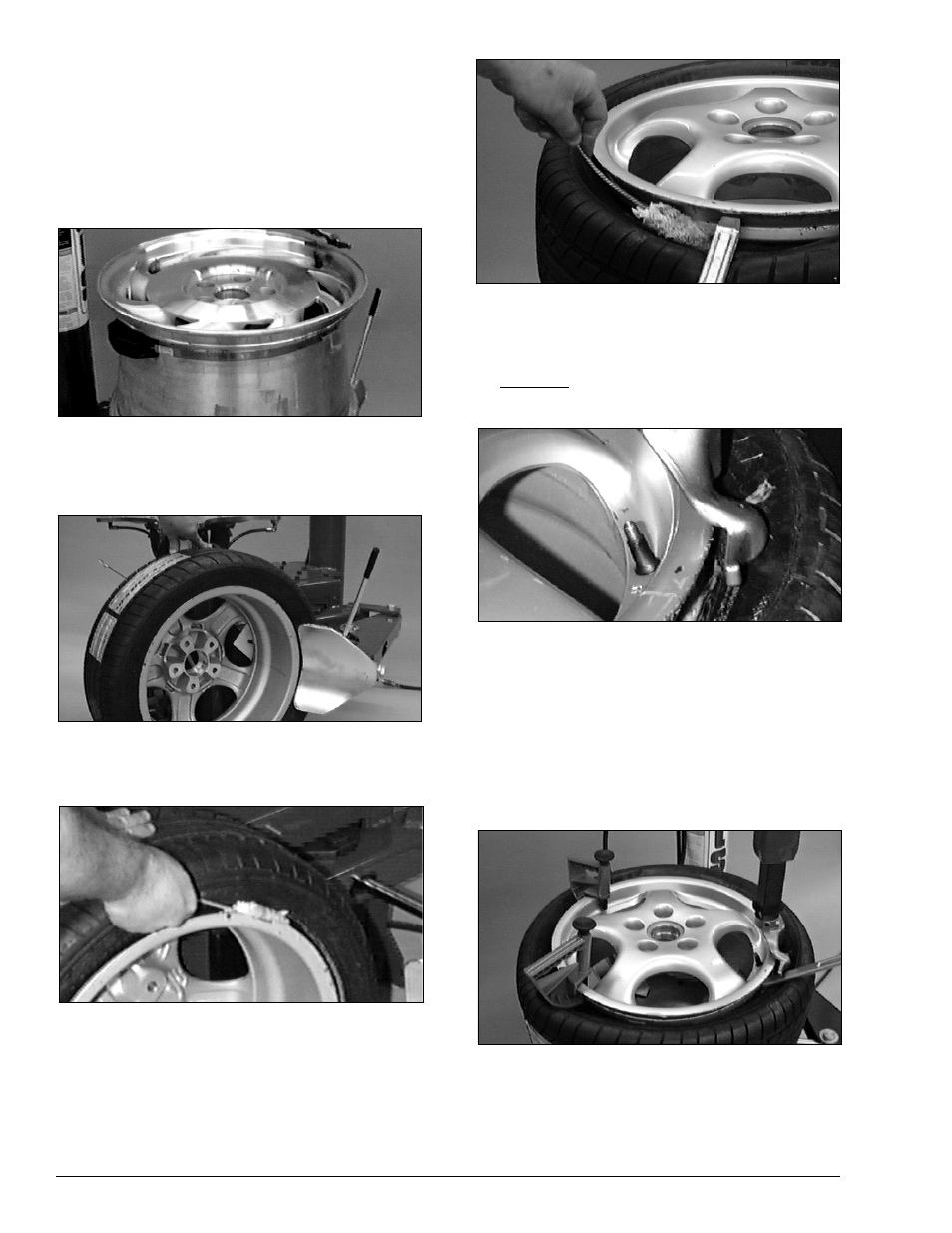

NOTE: Some wheels have a low pressure

sensor/transmitter strapped to the wheel. This is

especially true on run-flat tire/wheel systems. The

sensor is positioned directly opposite from the valve

stem. To avoid damaging the sensor, always loosen

the top bead at the valve stem first, then loosen the

bottom bead at the valve stem, and then continue to

loosen the remaining circumference of the beads as

necessary (Figure 20).

Figure 20 - Wheel with Low Pressure Sensor/Transmitter

3.

Loosen bottom bead, starting with valve stem

positioned directly next to the loosener shoe

(Figure 21).

Figure 21 - Loosen Bottom Bead

4.

Liberally lubricate the bottom bead of the tire

(Figure 22).

Figure 22 - Lubricate Bottom Bead

5.

Clamp the wheel to the table top as described in

item B on page 9. Always clamp custom wheels

from the outside.

6.

Lubricate upper bead liberally. Use the bead

lifting tool to help push the tire bead down so the

bead area is easier to reach.

Figure 23 - Lubricate Upper Bead

7.

Move swing arm into place and adjust as

described on page 4, steps 7, 8, and 9. Increase the

distance between the demount head and the wheel

an additional 1/16 to 1/8 inch with the adjustment

knob. Locate the valve stem directly under the

demount tool before proceeding.

Figure 24 - Position Valve Stem Under Demount Head

8.

Insert bead lifting tool between knob on

demount tool and tire bead. Pull lifting tool down

over wheel to lift bead up and over the knob.

NOTE: On asymmetrical hump wheels and stiff

sidewall performance tires, it may be necessary

to use 2 optional drop center tools (part

#435685) to hold tire in the drop center so that

the bead can be lifted over the demount tool.

Figure 25 - Insert Bead Lifting Tool (Optional Drop Center

Tools Shown)

9.

Hold lifting tool in place and depress the table

top control pedal momentarily to jog the wheel a

short distance.

10 • 5035 A/E Rim Clamp Tire Changer